The versatility of multi-compartment cement silos

Summary: Multi-compartment silos are very important for all those cement production plants that are willing to simplify their cement storage needs for different cement types. The main advantages of such a silo should be variable storage cells for the individual needs and to transport and distribute the cement from any of the individual compartments to any of the downstream loading, transport and packing installations. The present article summarizes experiences gained with installations IBAU HAMBURG has supplied in the last few years.

Globally there is a trend towards Portland-Composite Cements and Puzzolan cements. In Germany, for example, in the last 15 years the amount of CEM I cements has decreased from about 75 % to less than 30 %, while in parallel a number of different CEM II and CEM III cements have been introduced. In some developing countries such as India or Brazil, CEM I cement types still account for only a small proportion of the cement production. As the variety of cements in the production lines is increasing, multi-compartment silos are increasingly used in the terminal design. Such silos...

Globally there is a trend towards Portland-Composite Cements and Puzzolan cements. In Germany, for example, in the last 15 years the amount of CEM I cements has decreased from about 75 % to less than 30 %, while in parallel a number of different CEM II and CEM III cements have been introduced. In some developing countries such as India or Brazil, CEM I cement types still account for only a small proportion of the cement production. As the variety of cements in the production lines is increasing, multi-compartment silos are increasingly used in the terminal design. Such silos with capacities of more than 10000 t are predominantly made of concrete by using the central cone design, while other storage types have never gained practical market acceptance. The article will outline three examples, which have recently been installed in different countries around the world. The examples indicate that the success of the central cone design for multi-compartment applications is based on its versatility and the large number of design alternatives that are able to fulfil customer’s needs. All three terminals were constructed by the engineering company and technology provider IBAU HAMBURG.

IBAU HAMBURG introduced the central cone silo to the mar-

ket in 1975. The design is used for silos with diameters of

10 m to 30 m and above, for storage capacities of up to 40 000 t

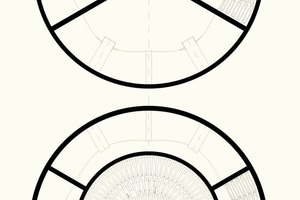

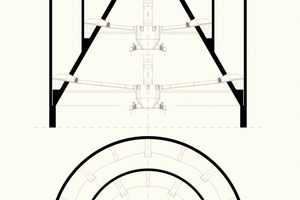

(Fig 1). Such large capacity silos for the storage of cement require an efficient and trouble-free emptying. The central cone has a displacement function for the material in the silo, to allow the material to come completely into motion during discharge. The central cone forms a ring space on the silo bottom, which is divided into individual aeration sections that are slightly downward inclined towards the discharge openings in the cone. The silo bottom is equipped with so-called open fluidslides (aeration pads) that have an air-permeable fabric on the upper side. The aeration air is blown under the fabric in order to fluidise the cement on the fabric. Each aeration section has its own discharge outlet with a flow control gate that provides a controlled discharge from the silo to the downstream collecting bin.

For silo discharge, one silo section is active at a time. This means only the fluidslides of one section are aerated and the relevant flow control gate is opened for discharge. The silo bottom

(Fig. 2) is aerated section by section, so that all sections are aerated in a complete cycle. Accordingly, only the bulk material above the actively aerated silo section is in motion and a flow channel above this section is formed. When the next silo section is aerated, the next flow channel is formed until the complete material in the silo is in motion and the silo level has been lowered. This refers to a mass-flow, in which the material is in complete motion after an aeration cycle. Only very small quantities of air are needed for the material discharge, and the aeration air is removed along with the discharged cement. The advantages of the IBAU discharge system are:

– complete utilization of the storage volume

– designed for 100 % safe operation

– no uncontrolled material movements within the silo

– no interruption during silo operation

– even discharge during an aeration cycle

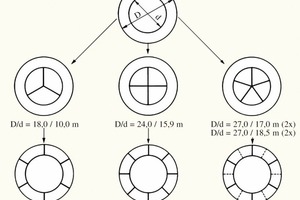

The central cone is able to carry ring loads as well as meridian loads with compression forces. Therefore the inverted cone does not restrict the separation into several compartments. Accordingly, different multi-compartment silo designs were developed (Fig. 3), of which the circular single design by separating radial diaphragm cells and the ring silo design have the most practical applications. The ring silo has two concentric circular walls, which form an inner circle and an outer annular cell (Fig. 4). Combining the ring silo concept with the radial cell design, the annular cell of the ring silo can be divided by diaphragm walls into several cells, in the same way as the inner circular cell.

Figure 5 shows different multi-compartment designs that can be evolved from the ring silo design. The separation into several cells by diaphragm walls can be done for the inner and outer cell simultaneously or for one of these cells only. Practically either the inner or the outer silo is divided into several cells. In case diaphragm walls are provided simultaneously for both cells, the pattern should be adapted preferably in such a way, that the inner and outer walls are in one line. This will reduce bending moments and restraint stresses in the walls and will allow a simpler installation of rebars during the slipforming process of the silo.

In the last few years IBAU HAMBURG has supplied a large number of multi-compartment silos for the cement industry. Most of these silos have been installed in Germany and other countries of Western Europe, as the use of blended cements in these countries is very advanced. Nevertheless a number of multi-compartment silos are now also operational in Brazil, Mexico, Turkey and other developing countries. With only a few exceptions, all these silos are unique and thus are not copies of any installation at a different location or for a different customer. Concerning safety practises, no compromise should be made [1]. The silos are mainly tailor-made designs, to fulfil the exact customer requirements for the number and tonnages of the different cement materials to be stored and the different distribution needs. Accordingly, just three examples of the wide variety of different designs are presented.

Holcim operates a 1.6 Mta cement plant (Fig. 6) in Dotternhausen/Germany. The plant is very unique because it uses oil shale for the production of cement. About 300 000 t of oil shale per year is supplied to the thermal treatment plant for electricity generation and the burnt oil shale is used as a hydraulic binder with up to 35 % contents in different Portland-burnt shale cements, corresponding to CEM II/A-T and CEM II/B-T cements. The oil shale saves costs for electric energy and provides the clinker substitute for low-CO2 cements. A smaller quantity of the burnt oil shale was used in Holcim cement plants in Switzerland. In 2008 Holcim decided in favour of a new rail and road-linked multi-compartment silo (Fig 7), to distribute different cement types to customers in Germany and to transport burnt shale to the Swiss cement plants in Eclépens and Untervaz by train. An investment of 7.5 million € was necessary for the new silo as well as for the reactivation and expansion of an existing railway track.

The multi-compartment silo has a capacity of 10 000 m3, 20 m diameter, 55 m height and a total of five cells. The silo has a raised bottom for direct bulk loading into trucks and rail cars. The outer ring silo has four compartments, each of 2000 m3, while the central (inner) silo has 9.5 m diameter and likewise a capacity of 2000 m3. The outer ring section compartments have two discharge sections each (Fig. 8), while the inner cell has one central discharge. Each discharge section is connected via fluidslides to one of the three IBAU Simplex loaders (Fig. 9), which provide a loading range of 4-5 m and 250 t/h loading capacity. Two of the mobile loaders are for the loading of railcars, while one mobile loader is used for the truck loading lane (Fig. 10).

The new Dotternhausen multi-compartment silo is in operation since January 2010. The fact that most of the cement and burnt shale transport is shifted by rail is in line with Holcim’s sustainable environmental policy. The railway partner in Germany is HzL (Hohenzollerische Bahn AG), in Switzerland it is SBB Cargo. A train with 13 rail cars has the transport capacity of 650 t. Both cement plants in Eclépens and Untervaz had to be upgraded for rail car unloading of the burnt shale. The first train to Switzerland was sent in May 2010, which significantly increases Holcim’s capacity of environmentally friendly Portland- burnt shale cements in Switzerland.

Hatien1 is part of the state-owned Vicem (formerly Vietnam National Cement Corporation or VNCC) and operates two integrated cement plants in the South of Vietnam. In 2010 the new 5500 t/d Binh Phuoc clinker production line went into operation. The new plant supplies the Phu Huu grinding plant in District 9 of Ho-Chi-Minh-City (HCMC) with clinker. The grinding plant (Fig. 11) consists of two clinker storage silos, two grinding lines and two cement storage silos. It is located at Tan Dien village, Phu Huu Ward and has water access for the clink-er supply and cement distribution to HCMC. The consortium HAVER & BOECKER/IBAU HAMBURG received the order for a second multi-compartment silo with 30 000 t capacity and two integrated packing plants.

The multi-compartment silo is of the ring silo design (Fig. 12). The outer silo diameter is 28 m, the silo height 71 m. The outer ring silo is divided into four cells, each with 5000 t capacity, the inner silo has 17 m diameter and 10 000 t capacity. The silo has a raised bottom for installing the packing plant with four truck loading lanes for bagged cement below the silo. A fifth loading lane in a separate building is for the loading of bulk cement onto trucks with a capacity of 150 t/h. The complete discharge capacity of the multi-compartment silo is 400 t/h. The terminal can also be used for the bulk loading onto barges (Fig. 13) as well the bag loading onto small boats (Fig. 14). The complete material handling capacity of the cement terminal is about 1.7 Mta.

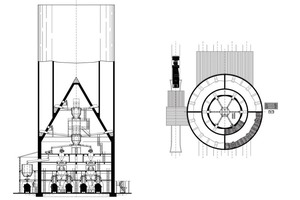

The Shurovsky plant of Alpha Cement, a Holcim subsidiary, serves the Moscow cement market. The plant is currently undergoing a modernisation and expansion programme leading to a new cement capacity of 2.1 million tons per year. IBAU HAMBURG was awarded the contract to modify the existing cement silos as well as to install two new ones [2], each for 20 000 t capacity (Fig. 15). Both new silos have a diameter of 26 m and a height of 60.5 m, one is designed as a single compartment silo and the other as a multi-compartment silo. The multi-compartment silo (Fig. 16) is of the ring silo design and consists of seven separate cells, which are for the storage of different types of cement. The inner silo has a diameter of 14 m and a capacity of 5500 t, while the outer ring is divided into six cells, each with 2500 t capacity.

The silo base of the multi-compartment silo is formed by a central cone, which is made from prefabricated elements

(Fig. 17). The inner cell has six aeration sections with a total of six discharge outlets with flow control gates. Each section has a right-hand side and left-hand side aeration sector that can be activated individually, in succession to generate small discharge flow channels. Each of the outer ring cells has four aeration sections with two flow control discharge outlets. Extraction rates from the silo cells are 250 t/h. As with all IBAU silos, only small quantities of air are needed for the material discharge and the aeration air is removed with the material. The flow control gates are automatically actuated, which ensures the controlled material flow from the silo cells. The new multi-compartment silo is equipped with four truck loading lanes. The designed daily truck loading time is 10 hours at four loading lanes, five days per week.

Multi-compartment silos are very important for all those cement production plants that are willing to simplify their cement storage needs for different cement types. The main advantages of such a silo should be variable storage cells for the individual needs and to transport and distribute the cement from any of the individual compartments to any of the downstream loading, transport and packing installations. These requirements need a high automation and that the material handling equipment is practically free of material residues, so that no undesired intermixing of different cement types occurs. Ring silo systems which are derived from the proven central cone design allow a versatility of designs to fulfil individual customer requirements. With their turnkey terminal capability, advanced silo technology, broad equipment solutions and worldwide references IBAU HAMBURG sets the industrial standards in this sector.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.