The industrial application of vertical roller mill separate grinding technology used in large scale raw mill

In this paper, the working principle and key equipment of vertical roller mill separate grinding technology is firstly introduced, then the updated technology scheme and application effect of the TRM53.4 and GRM53.4 respectively from Henan Jinrong, Henan Mengdian cement Ltd. are presented. Finally, a conclusion is drawn that the separate grinding technology can increase mill output by 10~20% and decrease electrical power consumption by 15~20%, which provides a good technology scheme for energy-saving and emission-reduction in the cement industry.

1 Introduction

The vertical roller mill is one of the large host units of the new dry cement production process, which adopts the principle of material layer grinding and has been widely used in the cement industry because of its compact structure, strong drying capacity, high grinding efficiency and easy large scale use. The vertical roller mill system and the roller press final grinding system are the mainstream raw material grinding systems. At present, under the same raw material and product fineness conditions, the roller press system usually has a lower power consumption than the vertical...

1 Introduction

The vertical roller mill is one of the large host units of the new dry cement production process, which adopts the principle of material layer grinding and has been widely used in the cement industry because of its compact structure, strong drying capacity, high grinding efficiency and easy large scale use. The vertical roller mill system and the roller press final grinding system are the mainstream raw material grinding systems. At present, under the same raw material and product fineness conditions, the roller press system usually has a lower power consumption than the vertical mill system by 2~3 kWh/t, which makes the raw material roller press system the first choice as raw material grinding system. However, the vertical roller mill has more advantages of large-scale compared to the roller press. For example, the raw meal grinding system for production lines with an output greater than 7500 t/d are generally equipped with two roller press systems, while a single vertical mill system has the ability to match production lines with an output of 10000 t/d. In addition, the vertical roller mill is more convenient than the roller press in terms of maintenance and overhaul. Therefore, the electricity consumption of the raw material vertical grinding system is the most critical factor limiting the application of large scale raw material vertical mills.

In response to the high electric consumption of the vertical roller mill system, the Tianjin Cement Industry Institute (in the following abbreviated as TCDRI) has developed the vertical roller mill gradient flow field series technology [1-6] since 2010 using a combination of theoretical research, experimental research and industrial application, significantly reducing the mill resistance and fan electricity consumption. Since 2014, in response to the common problems of coarse and fine particle mixed grinding and high electricity consumption of the vertical roller mill, the vertical roller mill separate grinding technology has been proposed. This technology improves the grinding efficiency and output of the vertical mill and significantly reduces the electricity consumption. The combination of vertical roller mill separate grinding technology and vertical roller mill gradient flow field technology provides a good systemic solution for the technology upgrade of the raw material vertical mill.

2 Principle and content of the technology

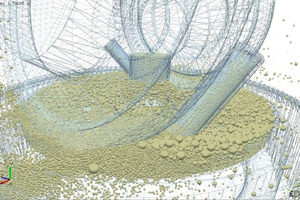

The vertical roller mill separate grinding technology is the basic grinding process technology of the vertical roller mill proposed by TCDRI for the first time internationally in 2014. It is a targeted solution to the common problem of unclear division of grinding zone and coarse-fine mixed grinding in the traditional vertical mill.The process flow of this technology is shown in Figure 1, and the main difference between it and the traditional vertical roller mill is the addition of a separator return powder dividing device, which has two main functions. One function is to separate the separator return coarse powder from the new feed and discharged material of the mill, and the other function is to convey the separator return coarse powder directly to the mill table grinding zone while the coarse material (new feed and discharged material) still follows the original process route of crushing first and then grinding.

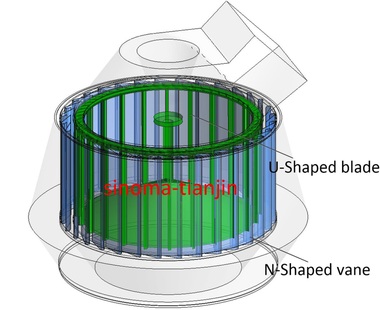

As shown in Figure 1, the vertical roller mill separate grinding technology has two key devices, which are the separator return powder dividing device and the grinding zone structure based on the separation of coarse and fine materials.

The main working principle of the vertical roller mill separate grinding technology is still the material layer grinding, but there are three differences from the traditional vertical roller mill material layer grinding process as follows:

The technology makes full use of the different crushing mechanisms of mutual extrusion between equivalent size particles and mutual extrusion between coarse and fine particles. The equivalent particle-size particles are particles of comparable particle size, and the grinding efficiency is increased through the mutual extrusion between particles with equivalent particle size.

The technology is fully based on the different crushing mechanisms of coarse particles and fine particles. Coarse particles are mainly crushed by squeezing pressure, while fine particles are mainly crushed by shearing force. The technology divides the grinding zone of the traditional vertical roller mill into grinding process zone and crushing process zone according to the function, and the crushing of coarse particles and grinding of fine particles are carried out separately and independently.

The grinding process zone is characterized by a “large velocity difference” and has a unique grinding zone structure. The returned coarse powder from the separator is directly conveyed to this zone for centralized grinding. The new feed material, which is conveyed to the center of the mill table, is first crushed in the crushing process zone of the grinding rollers and then sent to the grinding process zone under centrifugal force. In contrast, the grinding process of the traditional vertical roller mill is as follows: the returned coarse powder from the separator and the new feed material are firstly mixed in the separator down cone and the central feeding duct, and then falls onto the mill table together, and finally enter the bottom of the grinding roller under centrifugal force, so that the coarse and fine particles are ground and crushed in the mixed state.

3 Theoretical study of the technology

In order to study the effect of this technology theoretically, TCDRI has developed a numerical simulation platform based on the principle of “energy accumulation” and MBD multi-body dynamics coupling through its API secondary development interface based on EDEM commercial discrete element software.

The TRM5.6 test vertical roller mill was used as the research object, and the mixed grinding effect of the conventional grinding zone structure and the separate grinding effect for three grinding zone structures, including convex-concave engagement cone roller R111 (curved surface radius of curvature of 111 mm), curved-plane composite roller R80 (curved surface radius of curvature of 80 mm), curved-plane composite roller were studied by numerical simulation.

The torque curves of the mill table (Figure 3) and the output of particles below Φ50μm produced in the same time period were calculated from the simulation. The simulation data were calculated to obtain the output, mill power, and mill power consumption for each operating condition. The statistical averages under various working conditions are shown in Table 1. Under the same conditions, the separate grinding increases mill output by 67.6% and mill power by 39.6%, while the mill power consumption decreases by 16.7% compared to the mixed grinding.

4 Industrial application study of the technology

After three years of experimental and theory research, in order to verify the research results the industrial application of this technology was successively carried out in a Henan Jinrong TRM53.4 raw material vertical mill and a Henan Mengdian GRM53.4 raw material vertical mill in 2020, and good technical results were achieved.

4.1 Industrial application study of the technology in a Henan Jinrong TRM53.4 raw material mill

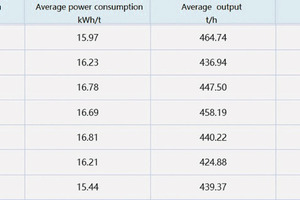

The raw material mill used in 2# production line of Henan Jinrong Cement Co., Ltd. is the TRM53.4 raw material mill of TCDRI, which was put into operation in 2012.After the output of the rotary kiln system was increased, the output of raw material grinding system could not meet the needs. After extensive research and comparison, the company finally chose the latest vertical roller mill separate grinding technology of TCDRI for technology modification. The operation of the raw material vertical mill before modification, whose annual average output is 457 t/h, R80μm is 13-16%, and R200μm is about 1.3% is shown in Table 2. The annual average power consumption of the mill was 7.34 kWh/t, and the annual average power consumption of the fan was 7.60 kWh/t, the total power consumption of the two items being 14.93 kWh/t.

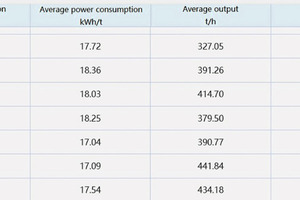

The mill was put into operation in April 2020 after technical modification, and after one and a half months of commissioning, the mill output, product fineness and power consumption all reached the contract guarantee index. The technically modified mill system and rotary kiln system were subjected to a 3-day performance assessment from July 4, 2020 to July 7, 2020. The results of the performance test are shown in Table 3. After the modification, the mill output increased by about 100t/h, an increase of 21.7%, and the total power consumption of the mill and fan decreased by 2.9 kWh/t, a reduction of 19.5%.

In June 2021, the company equipped the energy management system for the raw mill system of 2# production line. The energy management system statistics for the two months of July and August 2021 show that the average mill output was 550 t/h. In July, the mill power consumption was 6.26 kWh/t and that of the fan was 5.67 kWh/t, with the sum of the mill and fan electricity consumption being 11.9 kWh/t. In August, the mill electricity consumption was 6.0 kWh/t and the fan electricity consumption was 5.69 kWh/t, with the sum of the mill and fan electricity consumption being 11.6 kWh/t. The total power consumption of the mill and fan is below 12 kWh/t for the two months, which is basically in line with the performance test data in July 2020, fully proving the advancement and stability of the technology.

4.2 Industrial application study of the technology in the Henan Mengdian GRM53.4 raw material mill

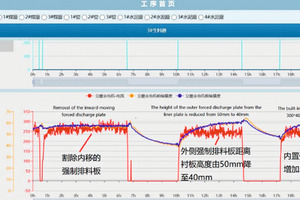

The Henan Mengdian’s 3# production line is equipped with a GRM53.4 raw material vertical roller mill from the Great Wall Machinery Company, which was technologically modified with TCDRI’s NU powder separator technology to improve production in 2018. However, the mill motor current was high due to the unreasonable match between the mill table and grinding roller. In July 2020, after the good application effect of the vertical roller mill separate grinding technology was proven in Henan Jinrong, the company adopted this technology for the technical modification of the raw material vertical mill.

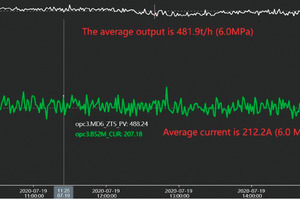

The mill, which had undergone the technical transformation of separate grinding, started commissioning from July 10, 2020. The mill commissioning was completed after about one week. The mill’s output has always been over 490 t/h, but due to the 400 t/h feeding capacity of the rotary kiln system, the mill is operated at 450 t/h to avoid long mill downtime affecting the kiln’s calcination operations and SO2 emission.

After the modification to separate grinding technology, the mill current is significantly reduced while the output is increased. While the output of the mill increased by about 50 t/h, its current decreased from about 240 A to about 210 A, and the mill power consumption decreased from about 8.2 kWh/t to about 6.6 kWh/t, a drop of 18-20%, which is basically consistent with the 16.7% reduction in mill power consumption derived from simulation calculations.

The comparison of power consumption in the energy management software before and after the technical modification (Figure 7 and 8) and the monthly statistics after the technical modification show that the mill output increased by more than 50 t/h, an increase of more than 12%, and the system power consumption decreased by more than 1.8 kWh/t, a decrease of more than 10.2%, which proves that the vertical roller mill separate grinding technology has good technology effects.

5 Conclusion

The vertical roller mill separate grinding technology is the basic grinding process technology of the vertical roller mill proposed by TCDRI for the first time in 2014. Theoretical, experimental and industrial application studies show that this technology can significantly increase mill output and reduce system power consumption. According to the simulation calculation data, test data and production statistics of industrial applications, the advantages of separate grinding technology over traditional mixed grinding technology are as follows:

(1) For the raw material vertical roller mill, the grinding efficiency can be increased by 29.7%, the output increase is 10~20%, and the mill power consumption reduction is 8~17% (the average value is 12%);

(2) In the raw meal grinding system, the fan power consumption is reduced by 8~12%, and that of the system is reduced by 15~20%;

(3) The vibration value of the mill is reduced by 40~50%, and the stability of the mill is significantly improved, which is of great significance for improving the life of key components such as the reducer, pressurization system and frame of the mill;

(4) The vertical roller mill separate grinding technology is stable and reliable, and its combination with the vertical roller mill gradient flow field technology can provide a good system solution for the technical modification of large raw material vertical mills. For medium abrasive materials (Wi=10~11 kWh/t), the power consumption of the raw material vertical roller mill grinding system can be reduced to about 13 kWh/t.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.