Industrial application of large raw material roller press finish grinding system

This paper introduces the large raw material roller press finish grinding system developed by Tianjin Cement Industry Design & Research Institute Ltd, which adopts newly developed equipment and process technology, such as the large raw meal roller press, new combined separator, low-resistance and high-efficiency cyclone, high-efficiency fan, and intelligent control technology. Industrial application shows that the optimal power consumption of the large raw material roller press final grinding system is only 9.1 kWh/t, and the average power consumption is 12.0 kWh/t. Compared with the other roller press systems, it has obvious power saving advantages.

1 R&D background

In the 1980s, TCDRI began to engage in the research and development of roller presses. After 30 years of hard work, TCDRI has always been at the forefront of technological innovation, leading the development of domestic roller press process technology and equipment. Nowadays, in addition to being used for traditional cement raw materials and cement, roller presses are also used for grinding materials such as slag, steel slag, and iron ore. In 2004, the first domestic cement roller press combined grinding system was put into operation. In 2013, the domestic largest roller press...

1 R&D background

In the 1980s, TCDRI began to engage in the research and development of roller presses. After 30 years of hard work, TCDRI has always been at the forefront of technological innovation, leading the development of domestic roller press process technology and equipment. Nowadays, in addition to being used for traditional cement raw materials and cement, roller presses are also used for grinding materials such as slag, steel slag, and iron ore. In 2004, the first domestic cement roller press combined grinding system was put into operation. In 2013, the domestic largest roller press TRP220-160 for cement raw material grinding was put into operation. In 2017, the first domestic steel slag/blast furnace slag roller press final grinding system was put into operation, with an annual production capacity of 600000 t. In 2018, TCDRI took the lead in realizing the industrial application of the cement roller press final grinding system.

In the current cement raw material grinding process, the roller press final grinding system has the lowest system power consumption.

According to the actual operation data of the raw material roller press final grinding system that has been put into operation, under the same condition of raw material grindability and product fineness, the system power consumption is 3~4 kWh/t lower than that of the vertical roller mill and 8~10 kWh/t lower than that of the ball mill. Therefore, in the past decade, the raw material roller press final grinding technology has been widely recognized in the cement industry, and has become the first choice for new construction or renovation projects.

After more than ten years of development, the final grinding technology of the cement raw material roller press has been very mature. In order to further reduce the power consumption of the system, and to be in line with international standards in the fields of energy saving and emission reduction, green production and intelligence manufacturing, TCDRI continues to explore the potential of energy saving technology for the raw material roller press final grinding system.

This paper mainly introduces the latest energy-saving technology developed by TCDRI and its industrial application, compares the operation of the raw material roller press final grinding system that was put into production at different stages, analyzes the reasons for the reduction in power consumption in detail, and puts forward the direction of future development.

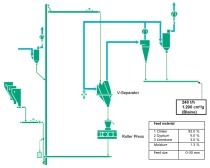

2 Technical characteristics of the process

The new feed materials are directly sent to the load bin above the roller press by the bucket elevator, and the materials squeezed by the roller press are fed into the V separator by another bucket elevator. After the materials are separated and dried in the V separator, the coarse materials are sent by the bucket elevator to the load bin above the roller press, and are then ground by the roller press. The finer materials are brought into the high-efficiency classifier by the wind for secondary separating. The qualified finished products are collected by the cyclone and transported to the product silo, while the coarse powder that does not meet the requirements of the finished product is returned to the V separator. The process flow is shown in Figure 1.

Technical characteristics of the latest raw material roller press final grinding system:

The latest process adopts the double bucket elevator. Compared with the scheme that adopted the single bucket elevator, it can effectively reduce the height of the frame and reduce the requirements on the capacity and machinery for the bucket elevator. At the same time,the roller press can be arranged on the ground, which is easy for repair and maintenance

The latest process has designed two sets of iron removal systems for new feeding materials and circulating materials. The perfect iron removal system ensures that large pieces of metal cannot enter the grinding area of the roller press, this effectively protects the roller surface with alloy stud, improves operational reliability, and reduces system maintenance costs and operating power consumption

In view of the large difference in raw materials of different cement plants, various types of feeding devices have been developed to improve the adaptability of the roller press to the raw materials and the grinding effect, and to reduce the power consumption of the system. Even if the raw material is aggregate scraps with a particle size of less than 5 mm, the roller press can operate stably

The combined separator can effectively control the residue of the 200 μm sieve and improve the quality of raw meal. At the same time, it can meet the drying requirements of the raw material with high moisture

3 R&D of energy-saving equipment

3.1 Large size roller press

With the increase in the scale of the cement clinker production line and the progress of domestic mechanical processing technology, a large raw material roller press has also emerged. In order to meet the needs of the 5000 t/d cement clinker production line, TCDRI took the lead in developing the TRP220-160 large raw material roller press in 2011, with installed power of 2×2000 kW and 2×2240 kW, which was the largest roller press in application in the cement industry in domestic at that time.

After nearly ten years of manufacturing and practical experience, TCDRI has continuously optimized the key components of large roller presses, such as rollers, roller supports, and hydraulic systems, etc. The large size roller press has the following characteristics:

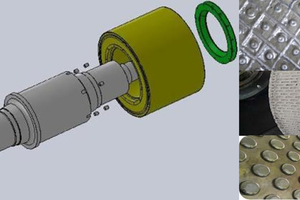

In order to improve the forging quality of the roller shaft of the large-size roller press, it adopts a split structure of the roller shaft and roller sleeve. At the same time, TCDRI has also researched a new wear-resistant roller surface, such as the build-up welding roller surface and cemented carbide roller surface, which greatly increase the service life of the roller shaft and greatly reduce operating costs. For medium-abrasive materials, the life of the cemented carbide roller surface with alloy stud can reach more than 30000 h (Figure 2)

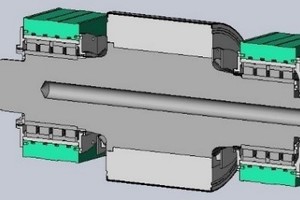

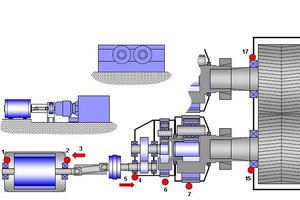

The roller support is mainly composed of bearing seat and bearing. The bearing seat of the fixed roller is directly connected with the frame, which improves the overall rigidity of the equipment and greatly reduces the vibration of the roller press. The bearing seat of the movable roller adopts the floating structure, and the movable roller and the bearing seat are integrally deflected during operation, which solves the problem of bearing sealing and improves the service life of the bearing effectively. The contact surface with the oil cylinder adopts a hinged connection, which can well solve the problem of uneven wear on the oil cylinder due to the deflection of the bearing seat, and double the service life of the oil cylinder. The bearing adopts four-row cylindrical roller bearings. Compared with spherical roller bearings, it has the characteristics of high bearing capacity, long life and good sealing performance. It can be several times longer than the double-row spherical roller bearings (Figure 3)

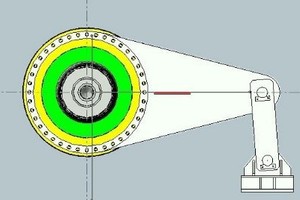

The simple torque support device transmits the torsion moment to the foundation, which makes the roller press run more smoothly (Figure 4)

The equipment has an advanced hydraulic system and automatic control system, which continuously improve the reliability of the equipment and reduce the failure rate. The hydraulic system of the roller press cooperate with the German Rexroth company and other professional hydraulic companies, and the key parts adopt the products of well-known international companies, so the highly integrated hydraulic system ensures the high reliability of the system. Each oil pipe of the system is provided by TCDRI, which makes the installation easier and with no need to flush the hydraulic system. Few pipe joints are designed to ensure that the system is leak-free. The large-diameter hydraulic cylinder adopts imported seals and proprietary technology make the service life longer (Figure 5)

The roller press can adopt a semi-direct drive permanent magnet motor which can reduce the speed at the input end of the reducer to 300~400 rpm, so the roller press runs more smoothly and the lubrication of the reducer can eliminate the water cooling process

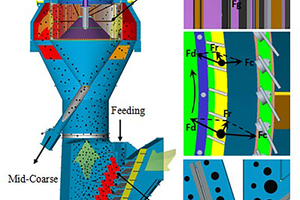

3.2 New combined separator

The separator is one of the important auxiliary equipment in the raw material grinding system, and the separation efficiency directly affects the stability and performance of the system.

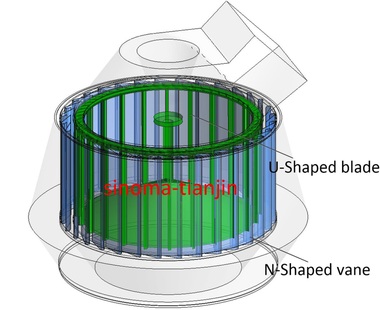

In order to improve the separation efficiency of the separator and reduce the power consumption of the system, TCDRI has researched and developed a new type of combined separator according to the characteristics of the raw meal grinding system. The new combined separator has the following characteristics:

The connection air duct between the V separators and dynamic separators is cancelled, which reduces the lifting height of the material, and reduces the resistance loss of the equipment and the power consumption of the fan. The operating data shows that the average resistance loss of the new combined separator is 2500~3000 Pa (including static and dynamic parts), which is more than 500 Pa lower than the traditional split separator

It can effectively control the residue of 200 μm sieve, to improve the quality of the raw meal. And it can meet the drying requirements of the raw materials with high moisture

TCDRI has researched and developed a new type of back incline rotor blade, which can reduce the rotor rotation resistance effectively. Under the condition of the same size rotor, the operating power of the separator can be reduced by 5%~10% and the power consumption of the separator can be reduced

The static part of the combined separators adopts a flat design, and the overall layout is more compact, which reduces the height of the equipment and the frame structure, and saves the investment cost in the early stage of civil construction

It uses a permanent magnet synchronous motor, which not only reduces the power consumption of the dynamic separators, but is also easy regarding operation and maintenance (Figure 6)

3.3 High efficiency cyclone and fan

In order to further reduce the ventilation resistance of the raw material grinding system, TCDRI optimized the structure of the cyclone and the system ventilation ducts. By optimizing the design of the cyclone and system ventilation ducts, combined with the optimization of the structure of the high-efficiency and low-resistance combined separator, the ventilation resistance of the raw material roller press final grinding system is greatly reduced, so the actual power consumption of the circulating fan is drastically reduced.

In addition, the newly developed raw material roller press final grinding system also adopts high-efficiency fans. The calibration results show that the efficiency of the fan has been increased from 70% to more than 82%, so the power consumption of the fan has been further reduced.

4 Intelligence of equipment and system

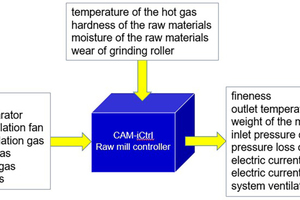

With the advancement of information and digital technology, on the basis of the existing grinding process and equipment technology, TCDRI has embedded information technology, intelligent technology and artificial intelligence technology into the entire cement manufacturing process to improve the product quality and production efficiency, and reduce the cement production costs, and promote the digital and informatized production in the cement industry. According to the characteristics of the grinding process, the raw material roller press final grinding system adopted non-linear model predictive control technology and established the neural network model using historical data, which solves the relationship between the feeding and the fineness of the final product, the non-linear gain of the return value of the coarse powder of the classifier and the return value of the feed, effectively solves the intelligent control of the grinding process, and further reduces the power consumption of the grinding system (Figure 7).

Through the real-time monitoring of the bearing temperature and equipment vibration, the working status of key components of the roller press can be predicted, thereby achieving planned maintenance and improving the intelligent level of the roller press equipment. The monitoring plan is shown in the Figure 8.

5 Industrial application case

In 2011, the first raw material roller press final grinding system developed by TCDRI was put into operation. By the end of 2020, about 80 sets of the raw material roller press final grinding system have been put into operation. Among them, there are 30 sets of large-size roller presses with roller diameters greater than 2000 mm, accounting for 37.5% of the total. According to statistics, the average system power consumption of the raw material grinding system is 12.0 kWh/t, the lowest is only 9.1 kWh/t, and the maximum capacity of a single system up to 650 t/h.

The following table shows the operation data of the large size raw material roller press final grinding system with daily output of 5000~6500 t clinker production line put into production.

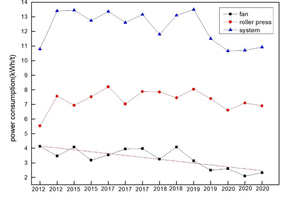

Analysis of the data in Table 1 shows that the power consumption of the grinding system with the contract signing date after 2019 is generally low, while the power consumption of the circulating fan has decreased significantly, which contributes most to the reduction of the system power consumption. The power consumption of several large size raw material grinding systems, such as CSNF and SMNF, which were put into operation at the end of 2020, is around 11 kWh/t, especially the maximum power consumption of the circulation fans does not exceed 2.6 kWh/t. This is mainly due to two aspects: First, the efficiency of the circulation fan has been improved, which has increased from about 70% to more than 82%, so that the power consumption of the fan has also been reduced by 0.35~0.4 kWh/t; second, by optimizing the structure of the combined separator, cyclone and other equipment, as well as the optimization of the ventilation ducts design, the ventilation resistance of the system is reduced greatly, so that the actual operating power of the circulation fan is also reduced greatly. Its contribution to power consumption reduction is about 1.0 kWh/t (Figure 9).

6 Economic benefit analysis

According to the statistical analysis of the actual operating data, the average system power consumption of the raw material roller press final grinding system developed by TCDRI is 12.0 kWh/t, and the advanced system power consumption is 9.1 kWh/t.

The raw material roller press final grinding system developed by TCDRI adopts the latest energy-saving technology and has obvious energy-saving effects. Compared with the other roller press systems, each ton of raw meal can save 1 kWh, which is equivalent to each ton of clinker with can save 1.5~1.6 kWh. Taking the 5000 t/d new dry process cement production line as an example, using the raw material grinding system developed by TCDRI can save 250000 kWh per year and save about 150000 RMB in electricity costs, which has significant economic benefits.

7 Conclusion

In order to improve the adaptability of the raw material roller press final grinding system, TCDRI has developed a series of energy-saving technologies: large size raw material roller press, new combined separator and low-resistance and high-efficiency cyclone, etc. At the same time, the system uses high-efficient fans. Actual operating data shows that the raw material roller press final grinding system newly developed by TCDRI has significant energy-saving effects, and the optimal system power consumption is only 9.1 kWh/t. Compared with other roller press systems, the raw material roller press final grinding system developed by TCDRI can save 1 kWh, which has significant economic benefits. At the same time, the system also has the characteristics of good raw meal quality and simple system operation. Up to the end of 2020, about 80 sets of raw material roller press final grinding systems have been put into operation. Among them, large-size roller presses with roller diameters greater than 2000 mm account for 37.5% of the total.

TCDRI has always insisted on optimizing the raw material grinding process and equipment technology, especially in the combined separator and the stand-alone machine and system intelligence, so the power consumption of the system is reduced by more than 10%, and the reliability is further improved. In the future, the raw material roller press final grinding system will continue to develop in the direction of being more energy-saving, more reliable and more intelligent.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.