The industrial practice of fuel and power saving at JSC Iskitimtsement

The cement industry is the most energy-intensive industry in the construction material sector. So it is no wonder that there are a lot of efforts to reduce the power consumption, especially in Russia, where are still a great many plants working according to the old fashioned and ineffective wet technology.

1 Introduction

The construction material industry ranks third in heat and power consumption after thermal engineering and metallurgy. The most energy-intensive industry in the construction material sector is the cement industry. In view of the fact that due to the prevailing use of the wet production technology in Russia, more than 200 kg of fuel equivalent, 120 kWh of electricity, and 5 t of construction materials are consumed to produce one ton of cement, the efforts to bring the power consumption down are quite relevant.

First, it appears appropriate to compare the most important technical...

1 Introduction

The construction material industry ranks third in heat and power consumption after thermal engineering and metallurgy. The most energy-intensive industry in the construction material sector is the cement industry. In view of the fact that due to the prevailing use of the wet production technology in Russia, more than 200 kg of fuel equivalent, 120 kWh of electricity, and 5 t of construction materials are consumed to produce one ton of cement, the efforts to bring the power consumption down are quite relevant.

First, it appears appropriate to compare the most important technical and economic parameters of the dry and wet methods of cement production based on the average data from Russia and worldwide (Tab. 1).

The above data show the undoubted advantage of dry cement production technology, especially in terms of the consumption of materials and power resources. However, changing the plant technology from wet to dry requires extensive capital investments, which makes it feasible to focus efforts on reducing the power costs at existing plants that use the wet technology, for which purpose it is necessary to consider the cost items of the heat balance of a kiln, the approximate values of which are shown in Table 2.

Considering that approximately 40 % of the heat is used for water evaporation, it is clear that reducing the moisture content in sludge and especially changing to the dry technology would reduce the heat consumption for clinkering significantly. The moisture content in sludge can be reduced with various known liquefiers. However, a reduction of moisture content in sludge alone often does not bring positive results, as this may increase the exhaust gas temperature and therefore the heat loss. Furthermore, it leads to a significant increase of dust discharge from the kiln, which is usually the main reason that restricts significant reduction of moisture content in sludge. Therefore, simultaneously with reducing the moisture content in sludge, the heat loss in the hot part of the kiln should be minimized.

2 Reducing heat loss in the hot part of the kiln

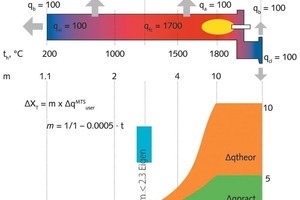

Reducing heat loss in the hot part of the kiln is an effective way to save fuel. According to the works of G. Eigen, which were developed significantly by V.K. Klassen [1], despite the relatively small heat loss in the hot part of the kiln, which amounts to about 12 %, reduction of these losses is important because it leads to significant heat savings for clinkering (Fig. 1). This is due to the fact that, according to the thermal engineering laws, high temperature heat has a big potential, and therefore the total heat savings ΔX increases by the heat loss factor m compared to the direct savings Δq.

The heat loss factor increases with temperature increase, and for a rotary kiln with the wet process it can theoretically reach a value of m = 10. G. Eigen actually achieved a value of m = 1.5-2.3, and we achieved a value of m = 2–5. Due to this fact, Eigen proposed referring to the high temperature zone of a kiln as the main thermal system (MTS), and the low temperature zone as the secondary thermal system (STS). [2]

Heat savings in the MTS can be provided by the following four methods, namely:

reducing the clinker production heat by changing the composition of the clinker raw meal, e.g., by using man-made raw materials, reducing the heat loss through the body by its insulation and establishment of a protective clinker coating

intensifying the heat exchange in the flame space through efficient fuel combustion

reducing the heat loss with the clinker

raising the temperature of secondary air

Let us now consider the last one of the heat saving methods. A grid cooler is a necessary and important unit of a kiln system. Its performance largely determines the fuel consumption for clinkering and its quality as well as the shape of the flame and the formation of protective rings and coating in the clinkering zone of rotary kilns and, therefore, the resistance of the lining. In this regard, optimization of heat and mass exchange processes in the cooler aims at providing a high heat efficiency of the unit, for which purpose it is necessary to implement the most complete and rapid cooling of the clinker with a minimum amount of cooling air.

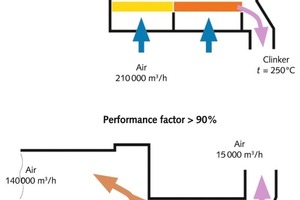

Modernization of the Volga grid cooler that was performed at JSC “Iskitimtsement” (Fig. 2) has increased the efficiency of the cooler from 0.68 to 0.85.

The kiln head seal and the aerodynamic performance of the cooler are of great importance with respect to fuel savings, formation of an optimal flame shape, and minimization of ring formation processes. With an increase of the proportion of cold air suction by 10 %, the secondary air temperature reduces by 50 °C, but as these losses occur in the hot part of the kiln, the loss is 3–3.5 kfe/t clinker (Fig. 3).

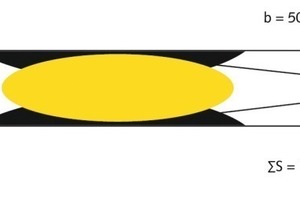

To reduce the proportion of cold air suction, the plant uses foreplates with replaceable top working parts, which provides a maximum seal in this unit of the hot oven (Fig. 4).

3 Burner facilities

The process fuel at JSC Iskitimtsement is gas, and the arrangement of the optimal flame during its combustion is of critical importance for reducing emissions into the atmosphere, producing high-quality products, high resistance of lining, and fuel savings. The plant uses DSB burners (diffusion swirl burners) designed by the Belgorod State Technological University named after V. G. Shukhov that are sufficiently in compliance with all the requirements for burner facilities.

4 Use of combustible waste in wet technology

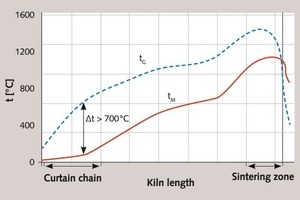

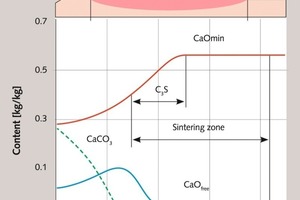

JSC Iskitimtsement together with the Department of Cement Technology and Composite Materials at BSTU developed and implemented the technology of using coal washing waste in the production of Portland cement clinker. The wet technology makes it possible to apply a more rational option of using materials that contain flammable substances, namely, joint grinding of the man-made product (waste) with traditional raw ingredients. This technology is based on the fact that in a rotary kiln the heat transfer takes place through the surface layers of the material, and the temperature difference between it and the gas flow is more than 700 °C (Fig. 5). Therefore, in the temperature range of volatile sublimation from the fuel (at 200-400 °C), the gas temperature exceeds 900 °C, and therefore more complete combustion of the combustible mass is provided.

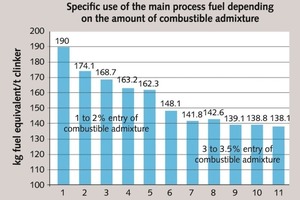

Under these conditions, a predetermined stable chemical composition of the sludge is achieved, as during the joint grinding of the raw ingredients and fuel-containing man-made materials technological adjustment is made in the traditional way. Thermal engineering calculations and the experience of using coal washing waste supplied by Sibantratsit LLC at JSC Iskitimtsement showed that every one percent of combustible mass added to the sludge saves about 15 kg of fuel per one ton of clinker. The combustion heat of the combustible component usually does not fall below the value QrH = 30 MJ/kg. When its content in the dry raw meal is an amount of 1 %, fuel savings amount to ~ 15 kg/t or 450 MJ/t, which corresponds to (~ 450/29.3) ≈ 15 kfe/t clinker.

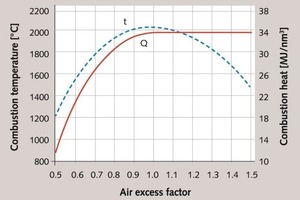

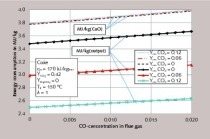

However, with the addition of combustible admixtures (coal washing waste) to the sludge one should consider some features of the rotary kiln operation, which are due to the need to have a sufficient amount of oxygen in the pre-kiln zones to ensure combustion of fuel that is contained in the sludge. It is this circumstance that determines the possible amount of combustible mass addition to the sludge, as the shortage or a great excess of air in the flame space reduces the flame temperature and therefore the heat transfer in the sintering zone (Fig. 6). Therefore, when the air excess factor rises above a certain value, the flame temperature that is necessary to ensure a normal clinkering process is not achieved.

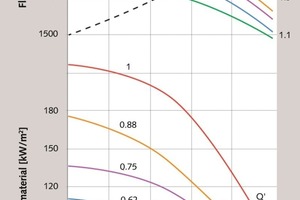

Based on numerous tests, the physical and chemical transformations of material in the flame space of a 4.5/5 × 170 m rotary kiln were found (Fig. 7). Calculations on the basis of experimental data show that for a normal clinkering process, the heat flow must be at least 100 kW/m2. This heat transfer value will be determined by the flame temperature and the length of the sintering zone, which in their turn depend on the concentration of the combustible component that is added to the sludge, the cooler efficiency, and the air excess factor. The relations of these parameters, which are shown in Figure 8, demonstrate that when the cooler efficiency is 0.88, the maximum allowed concentration of the combustible admixture in the sludge should not exceed 3.8 %, and the flame temperature should not be less than 1680 °C at a = 1,5 (point A).

In case of impairment of the cooler operation, such as an efficiency decrease from 0.88 down to 0.62, the required Q = 100 kW/m2 can be achieved at 1.28 and just 2 % combustible admixture can be added (point B). A decrease of the cooler efficiency below 0.55 virtually eliminates the possibility of introducing a combustible admixture into the sludge with an unchanging kiln productivity. However, if the absolute heat consumption and heat capacity of the kiln remain constant while the cooler efficiency goes down, and therefore the kiln productivity and Q are reduced proportionally, the possibility of introducing the admixture will be determined by the inclined line Q’. Under these conditions, even with an efficiency of 0.5, it is still 1ossible to introduce up to 1 % admixture (point C), and the required heat transfer is achieved at tf = 1640 °C. As the efficiency of grid coolers is usually 0.75 or more, one can confidently introduce up to 3 % combustible admixture with coal waste, which will save 45 kg of burner oil equivalent per ton of clinker.

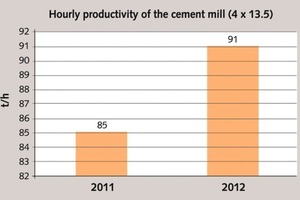

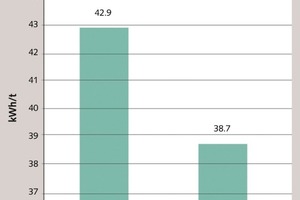

At the same time, there are three more positive effects. The organic component of man-made materials is usually a liquefier and an intensifier of sludge grinding, which naturally leads to a reduction in its moisture content and increased productivity of primary mills and therefore power saving. Moreover, the clinker produced from raw meal with combustible admixture has higher grindability, which raises the productivity of cement mills and thus provides additional power savings. Experience shows that the total heat consumption for clinkering is reduced when a combustible admixture is used.

The efficiency of implementation of combustible admixtures at the cement plant of JSC Iskitimtsement in 2012 and the first nine months of 2013 are shown in Figures 9-11 and Table 3.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.