The future is today

The Internet of Things – which is an essential part of the German initiative Industrie 4.0 – is synonymous with the digitalization of industrial processes. A core element is that process industries become more intelligent. Cement companies, too, can profit from technologies that increase digitalization and at the same time tackle the challenges facing the industry.

1 Introduction

Immense cost pressures – Consolidation of market players – The need to construct new sites more quickly and efficiently: These are just some of the challenges companies in the cement industry have to deal with. Part of the answer can be found in how cement firms use technology to organize themselves and their business processes. Simply put, digitalization can serve as a valuable tool to help cement managers do their jobs even better.

2 More digitalization

The idea of expanding the use of technology and IT to gain a competitive advantage is nothing new. Basically, this is the...

1 Introduction

Immense cost pressures – Consolidation of market players – The need to construct new sites more quickly and efficiently: These are just some of the challenges companies in the cement industry have to deal with. Part of the answer can be found in how cement firms use technology to organize themselves and their business processes. Simply put, digitalization can serve as a valuable tool to help cement managers do their jobs even better.

2 More digitalization

The idea of expanding the use of technology and IT to gain a competitive advantage is nothing new. Basically, this is the cornerstone of a movement to embed more and more objects with electronics, sensors and software, and allow the objects to communicate with one another via the Internet. Fittingly, the term Internet of Things has been coined for the trend. For many branches of industry, the Internet of Things is seen as a spearhead for a revolution in manufacturing. In Germany, it is an essential part of Industrie 4.0 – an initiative of the German automation industry sponsored by the German government. The objective is to define the way forward for manufacturing companies in the Internet age.

Thomas Walther, who is in charge of Cemat at Siemens, says that Industrie 4.0 means introducing more intelligence to process industries over the entire lifecycle: “From planning to commissioning, including operations and maintenance, more steps that were previously completed manually will be done without human intervention.” A significant aspect is the role played by more and more complex sensors. “Sensors are developing at amazing pace. Just a few years ago, for example in the home environment, it was possible to measure only the temperature and have it relayed to a smartphone,” says Walther. “I now have sensors in my house that can also measure humidity and register the degree of shade.” The sensors used in industrial settings have also become similarly more complex, he says. However, the data only really becomes useful when it is interpreted and new insights are gained.

Some industries have been quick to adopt a higher degree of digitalization in their processes and are already closer to this vision of Industrie 4.0. A forerunner in this regard is the automobile industry. The cement industry, however, is still at the beginning. Consequently, it is time that cement companies embrace innovations that have proven their value in other sectors.

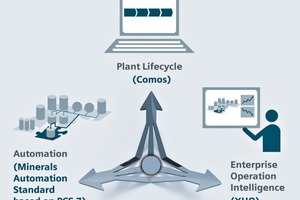

When thinking about where Siemens can offer well-proven elements from other sectors for the specific challenges of the cement industry, three solutions stand out in particular: end-to-end process automation and instrumentation; the engineering and application software Comos for the entire plant lifecycle phase which in turn serves as a basis for completely digitalized production; and a software platform like XHQ (eXtended Head Quarters) that collects data from a number of sources to give decision makers and management a real-time condensed overview of all information so they can make the best decisions possible.

3 Automation: the rock-solid basis

For quite some time, Siemens has been laying the groundwork for automation and digitalization. Almost 50 years ago, electrical engineering was integrated into automation technology thanks to the transistor. The introduction of Totally Integrated Automation (TIA) in 1996 enabled the coordination of components in production processes, allowing companies to closely integrate their software and hardware. Siemens has since continuously enhanced the TIA offering. In 2007, the company introduced a comprehensive family of product lifecycle management (PLM) software, to which it is continually adding more modules. The aim of PLM software is to optimize product development. And to achieve this goal, design, prototype development and simulation take place in the virtual world so that development times can be significantly reduced.

In the cement industry, the groundwork for the journey toward digitalization starts with rock-solid automation – automation that boasts the highest availability, reliability and efficiency possible. Automation can be seen as the brain, a closely knit network of sensors and instruments as the eyes and ears, and integrated drive systems as the muscles. Cemat is Siemens’ process control system for the specific requirements of the cement industry. With over 800 installations worldwide, Cemat has become the leading process control system for the cement industry and related branches. More than 40 years of matured functionality for automation of cement plants are combined in the solution. With a migration concept incorporated into the automation, the investment of a client is protected and at the same time the operator can profit from the latest innovations in the software standard.

Cemat ensures that operators receive the best support for performing their duties. Innovative and proven functions for operation and integrated maintenance functions assist in fast diagnosis of potential faults – even before the appearance of a problem. Downtimes are thereby reduced. The cement-specific library provides the best route to increased operational efficiency. Especially in regard to engineering: predefined and proven functional modules and faceplates for many applications and processes make engineering easy, fast and reliable. Cemat utilizes the modern process control system Simatic PCS 7 with its open, flexible and scalable architecture as its system platform. The advantage of a high level of automation is that operators know the status of each piece of mechanical equipment.

Automation alone isn’t enough – everything has to be connected with one another. The introduction of fieldbuses and their functional expansion to include isochronous operation and direct data exchange between plant sections set the basis for the increasing integration of drives and automation. It has also become possible not only to program connected controllers from a programming device or PC, but to also implement “intelligent drives” via one and the same communication bus. Products and systems can therefore be incorporated reliably into the automation from any distance via communication-enabled devices, switches and connection modules. This increases transparency throughout the production process, and enables consistent data management, standardized operating and monitoring, as well as consistent engineering in distributed automation structures.

Only when a control center has access to all the data at a cement plant can it begin to leverage that data to improve overall day-to-day operations. Cement manufacturers that operate several sites with Cemat profit from being able to easily compare KPIs at different sites. Naturally, synergies can also be more easily exploited among a company’s sites.

4 Savings with smart engineering and beyond

Mounting cost pressures, particularly for energy, have many operators taking an even closer look at their consumption figures. Siemens has a wealth of experience in saving energy, for example with highly efficient drive trains in which all components are ideally designed to fit with one another. For existing systems, Siemens performs energy audits in collaboration with customers to produce a transparent picture of all consumers in a cement plant and to identify potential to reduce energy consumption. The audits also include a return-on-investment calculation. End-to-end automation, of course, makes carrying out an audit a great deal easier. At several asphalt plants in the UK, production and energy data have been collected and analyzed using a cloud solution. Through data analytic services, potential to save energy was identified, an after implementation resource efficiency improved so much that EBIT increased by 25 %.

There is, though, another solution from Siemens that can help save money, and not just in the operations phase: Comos, the plant engineering software platform. The software solution contains applications for all plant lifecycle phases, from engineering and operations to modernization as well as dismantling. For cement manufacturers in particular, Comos holds the greatest potential for constructing new plants quickly and efficiently.

At the heart of a plant operating with Comos is a common database. Because all data is always available and up to date, it depicts the actual as-built status of a plant at all times. This is especially helpful in planning modernizations, since there is no need to catalogue the current status of a plant with the arduous task of updating old plans. Formerly separate fields such as process technology, mechanical and electrical engineering, and control technology are all combined into the standardized data structure of Comos. Furthermore, Comos simplifies data exchange between partners and suppliers, thereby helping to avoid misunderstandings.

A special aspect of Comos is the range of software solutions for the entire plant lifecyle. Three applications come to the fore in the engineering phase: Comos Platform provides a basis for effective overall data management. The creation of process data and all aspects of process engineering are covered in Comos Process. Comos Automation supports electrical engineering for a plant through to full automation covering all processes relevant to electrical, instrumentation and control engineering. Comos Automation also has a Simatic PCS 7 interface for exchange and software engineering with a distributed control system (DCS). All data created during the engineering phase can be reused in the operational phase.

For the operational phase, Comos Operation assists in implementing an efficient plant support strategy. Available applications include solutions both for maintenance during ongoing operations and overhaul during shutdown. Comos Lifecycle supports comprehensive information management throughout all plant lifecycle phases. The benefit is maximum reliability in decision-making. Plant operators have worldwide access to data and documents, so they can react quickly to changing market demands. “Perhaps one of the greatest advantages of Comos is that changes made in one application are immediately reflected in all other applications,” says Walther. Cement plants operating with Comos enjoy significantly lower costs – by approximately 60 % – and less effort and time are needed for daily operations. And with completely up-to-date engineering models, it is not unheard of for throughput time to be reduced by more than 50 %.

A number of industries are already benefiting from Comos. In pharmaceuticals, the Swiss company Novartis Pharma AG in close cooperation with Siemens launched a program for a standardization of its engineering worldwide. Since 2004, Novartis Pharma has been successfully using the Comos software solution for the purposes of plant engineering, lifecycle data management and plant documentation. In the meantime, the entire engineering at the main production sites – including process technology as well as electrical, measurement and control technology – has been carried out exclusively with Comos. The customer reports significant improvements in terms of efficiency and quality.

5 The big picture with XHQ Enterprise

Operations Intelligence

Comos offers worldwide access to data and documents, but that is generally not enough to make the most informed decisions. Therefore, Siemens offers XHQ Enterprise Operations Intelligence; XHQ stands for eXtended Head Quarters. Originally created for the oil and gas industry, XHQ has long found use in other sectors to aid in improving operational excellence through the collection and intelligent use of data.

In companies with several sites, operations personnel typically struggle to pull together a complete, timely picture of a situation. Like missing pieces of a puzzle, critical information is often scattered throughout a variety of databases, enterprise applications and operational systems in a wide range of formats with a confusing mix of unrelated contexts. Only when this information comes together in a meaningful way can it be used to react to a given situation. For that reason, XHQ extracts, aggregates, relates and presents operational and business data from a variety of information sources. XHQ provides users with a wide, unique range of coherent, up-to-the-minute information. This data is then used to monitor performance and make better, more informed, actionable decisions – for greater efficiency and reduced costs. XHQ can be easily customized for each user.

The true advantage of XHQ comes from the fact that decision makers have relevant, personalized and easy-to-understand information at their fingertips. A series of production plants can be tracked in real time, and the data can be compared, for example, with price indices, KPIs and other company production sites. This information allows operations performance to be taken to the next level. Answers to questions such as how are we doing against objectives, how are we doing collectively, and what should we do in this situation given current conditions can be answered easily with XHQ.

For the cement industry, XHQ gives operators access to real-time information that can strengthen the ability to maintain performance of a series of plants, wherever they may be in the world. With XHQ, operators can monitor equipment performance within specified operating parameters, based on a metrics strategy. Operators can reduce the probability of operating limit exceedances using alarms, alerts and notifications to ensure the most effective troubleshooting. Access to this equipment health monitoring data can be made available to operations managers, equipment operators, sensor vendors and service personnel to provide important transparency for equipment health, and thus can be used to improve and sustain cement operations.

6 Great potential for cement

All of the solutions described above are available today – and they have been employed in different industry sectors all over the world. “Until now, there still isn’t a cement industry reference in which all the solutions we mention here have been installed,” says Walther. However, as more and more companies make investments in digitalization, he is optimistic that it won’t be long before there is one.

The challenges facing the cement industry today do not look like they will disappear anytime soon. The possibilities of digitalization, however, can ease the way. Siemens is using its expertise to help the cement manufacturers become more effective and save money. The only prerequisite is a willingness to embrace innovation. With more digitalization comes access to the most up-to-date information. So whether we’re talking about cost pressures or market consolidation, operators can find the best solution to ensure profitability.

//www.siemens.com/mining" target="_blank" >www.siemens.com/mining:www.siemens.com/mining

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.