Greater productivity in industry thanks to digitalization

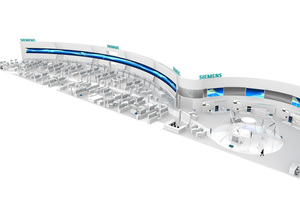

Under the motto “On the Way to Industry 4.0 – Driving the Digital Enterprise,” on the upcoming Hanover Fair (13.-17.04.2015) the Siemensstand in Hall 9, D35, offers an overviewof the company's extensive portfolio for industrial customers over an area of 3500 m2. Core topics are “Future of Manufacturing” and “Sustainable Energy.”

Digitalization has developed into a decisive lever for growth in practically every sector of industry. Because digitalization is the central key to greater productivity, efficiency and flexibility, it forms the focus of the Siemens presentation at the 2015 Hannover Messe. Speaking at the press conference prior to the fair, CEO of the Digital Factory Division Anton S. Huber said: “True gains inefficiency can only be achievedtoday by optimizing andnetworking systems and processes along the entire product and production life cycle. Digitalization opens up whole new scope for producing companies...

Digitalization has developed into a decisive lever for growth in practically every sector of industry. Because digitalization is the central key to greater productivity, efficiency and flexibility, it forms the focus of the Siemens presentation at the 2015 Hannover Messe. Speaking at the press conference prior to the fair, CEO of the Digital Factory Division Anton S. Huber said: “True gains inefficiency can only be achievedtoday by optimizing andnetworking systems and processes along the entire product and production life cycle. Digitalization opens up whole new scope for producing companies to develop and manufacture products and solutions quickly and efficiently. Anyone who consistently leverages these opportunities will benefit from a decisive competitive edge”.

Over an exhibition area of 3500 m², the Siemens booth D35 in Hall 9 will feature a wide range of solutions and products from its group-wide growth fields of electrification, automation and digitalization under the banner “On the way to Industrie 4.0 – Drivingthe Digital Enterprise”. As well as the integration of renewable energies into the energy system, a variety of industrial solutions such as Totally Integrated Automation (TIA), Integrated Drive Systems(IDS), Industry Softwareand plant data services will all be featured in the Siemens presentation. Also located within the booth will be the “Digitalization Forum”, where Siemens will be presenting concrete examples of digital technologies in application in the manufacturing and processindustry as well as machine building.

Siemens offers a future-proof platform based on high-performing software technologies aimed inparticular at customers from the manufacturing industries under the title of “DigitalEnterprise”, which will allow the extensive demands of Industrie 4.0 to be met over the coming years. “We already have the capability for full integrationof the entire production and production lifecycle. This allows us to enhance the productivity and efficiency of our customers and so boost their business”, explains Anton S. Huber. Siemens pays particular attention here tomerging the virtual with the real world by demonstrating that the digital factory is no longer just a vision.

Siemens is also breaking new ground in the process industry. “Current market trends are moving in the direction of modularization, digitalmapping of production steps and communication between the individual machines in the plant,” said Peter Herweck, CEO of the Process Industries and Drives Division. Thus, Siemens’ portfolio for the process industry offers sustainable solutions from design and engineering to maintenance and modernization.

At the stand’s “DigitalizationForum,” a hydraulic circuit demonstrates digital integration of a componentin the existing plant. Planning and engineering with the software solution “Comos” in conjunction with the “Simatic PCS 7” process control system enable data from engineering and automation to be pooled. “Comos Walkinside” visualizes the integration realistically in 3D.

A key step toward the digital plant is simplified administration in industrial networks. Siemens is presenting a current project on this topic at the Hannover Messe, named: “Effortless Communication.” Assignment of addresses from engineering is relocated to the automation devices. As a result, devices can automatically assign themselves unique addresses without the need for a central instance such as an address server. Moreover, the system simplifies the use of remote services and increases their security. The results from the project might be used to build and run future production networks.

In the field Integrated Drive Systems (IDS), Siemens is presenting new drive technology components. “Simotics” reluctance motors offering maximum energy efficiency and dynamism, a new shaft height for the “Simotics”FD low-voltage motors,and the modular “Simotics” HV M high-voltage motors expand the extensive portfolio. As customers from process industries today have to deal with a high degree of complexity, yet strive for maximum energy efficiency, IDS offers a comprehensive, end-to-end range of integrated drive systems. Almost any Siemens drive component can be integrated seamlessly into any drive system, any automation environment and the plant’s entirelifecycle.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.