The difference is in the detail

Drywall construction with plasterboard is simple and opens up a variety of options for architects, construction clients and DIY enthusiasts. As a result, the recycling of mixed construction waste with a high gypsum content is also becoming increasingly important. The efficient and economic recycling of gypsum-containing waste requires the latest technologies at every stage of the process – from process engineering right through to automation.

1 Introduction

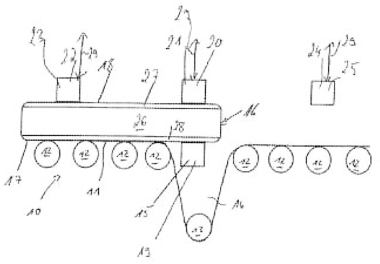

The German recycling company MUEG Mitteldeutsche Umwelt- und Entsorgung GmbH, founded in 1990, has been operating a new recycling plant (Fig. 1) for plasterboard panel construction waste (Fig. 2, 3) since the summer of 2014 in Großpösna near Leipzig, Germany. The plant was conceived by Martin Eves, CEO of the Irish company EGRS Ltd., a company that specializes in the design of gypsum recycling plants.

For more than ten years, he has been working closely with the German company Neuenhauser Maschinenbau GmbH. With roughly 2500 em-ployees around the world, the company builds systems...

1 Introduction

The German recycling company MUEG Mitteldeutsche Umwelt- und Entsorgung GmbH, founded in 1990, has been operating a new recycling plant (Fig. 1) for plasterboard panel construction waste (Fig. 2, 3) since the summer of 2014 in Großpösna near Leipzig, Germany. The plant was conceived by Martin Eves, CEO of the Irish company EGRS Ltd., a company that specializes in the design of gypsum recycling plants.

For more than ten years, he has been working closely with the German company Neuenhauser Maschinenbau GmbH. With roughly 2500 em-ployees around the world, the company builds systems for environmental and process engineering. Martin Eves emphasizes: “The special feature of our systems is that we can separate valuable gypsum from construction waste containing a very wide range of contaminants and a particular moisture content. In addition, the use of specialized process technology makes the system energy-efficient.”

At full load operation, the recycling plant is designed to separate approximately 200 to 300 metric tons of construction waste per day and convey the individual materials to the correct containers for further transporting (Fig. 4). Martin Eves sees a promising future for such plants, because German recycling legislation, such as the current Waste Management Act, requires the environmentally-friendly but above all high-quality recycling of used products – as well as the prioritization of the use of recyclable waste in the manufacture of those products. The gypsum industry is now tapping into the options associated with this.

2 Powerful soft starter

Sophisticated process engineering and design considerations that enable the systems to work efficiently and fault-free are crucial to the efficient and economical recycling of gypsum waste. “This makes system integration an important aspect for us,” explains Carsten Wellhöfer, Project Manager and Head Project Engineer at Neuenhauser, who was also involved in the installation of the recycling plant in Großpösna. That’s why Neuenhauser employs control and switching system solutions from Siemens almost without exception. In addition, when working on a new project, the machine manufacturer also takes advantage of any opportunity to optimize the control engineering by using the latest technical innovations. This way, with state-of-the-art products, the company is able to offer its customers a maximum in terms of added value.

Just such an opportunity was presented by the latest version of the Sirius 3RW44 soft starter (Fig. 5) from Siemens. The device has been part of Neuenhauser’s standard repertoire for many years, but has now been implemented with an integrated Profinet interface for the first time. Christian van der Kamp of the Electrical Engineering Department at Neuenhauser reports: “Our plants now communicate primarily via this powerful bus system, and because the soft starter is available with a Profinet interface, we can save on the additional costs that would have been associated with an additional fieldbus” (Fig. 6).

3 High level of functional integration

The device ensures soft starting of the main grinder (Fig. 7 that powered by a 90 kW electric motor and attached gear unit. The drive is subject to severe stresses from the contaminants in the recycling waste. To minimize these stresses, the parameters of the soft starter can be precisely adapted to the operating condition using the Soft Starter ES software. Christian van der Kamp explains: “At the start of the five-second power-up ramp, we can increase the voltage to increase the torque on the electric motor and the rollers, for example.”

He sees great benefits in being able to adjust individual parameters according to the particular situation. Following the initial breakaway pulse, the voltage can be reset to 70 % of the rated value (400 V) and steadily increased to 100 % by the end of the power-up ramp. “This model has proved practicable,” he says, as the contaminants in the waste frequently require high breakaway forces. In the event that anything does actually get caught between the rollers, the permanent current measurement integrated into the soft starter indicates this.

The controller immediately detects the sharp rise in current and switches off. Reverse operation is then triggered to clear the blockage in the rollers. “Previously, we had to provide an additional current transformer for current measuring, but now we can dispense with this entirely”, says the control specialist. Another design solution from this time was to monitor for blockages using an additional speed monitor – an approach that has now also been rendered obsolete.

The soft starter simplifies many things. For example, in the case of system blockages, the current flow can quickly reach four to five times the rated current before shutting down. “Thanks to the rugged design of the Sirius 3RW44, such brief overloads are still within the specification of the device,” explains Carsten Wellhöfer.

4 View logs – on the device or remotely

In addition, the device switches to a contact bridging system following the thyristor-controlled ramping and the current is routed through directly, essentially in the form of a bypass. This results in the 3RW44 soft starter only having power losses of 95 W after power-up. This saves energy, and is in keeping with the ecological philosophy of the gypsum recycling plant.

EGRS-CEO Martin Eves explains: “Like our partner Neuenhauser Maschinenbau, we rely on modern technology and system integration. This way, global support can be provided via remote service to maintain maximum plant availability.” Carsten Wellhöfer emphasizes: “Standardized solutions are a decisive factor for the functionality and long-term reliability of such plants.”

The parameters and operating values of the soft starter can also be accessed directly either via modem or the plant control at MUEG’s new gypsum recycling plant. It is the logs recorded by the device, however, that are of primary interest to the programmer from Neuenhaus. They allow for the detection of specific (peak) values or events from the data history, or the creation of selective fault analyses using trends in the values (Fig. 6). “The whole process is very simple, regardless of whether you are working directly on the device or with ‘Soft Starter ES’ via remote service,” he explains.

5 Rugged complete solution

The inaugural use of the Sirius 3RW44 soft starter from Siemens with Profinet communication in the new gypsum recycling plant has confirmed: consistent modernization and optimization always result in improved designs. Using the Profinet-enabled soft starter meant that it was possible to dispense with an additional bus system. In addition, the integrated current measurement feature allows you to operate without additional current measurement equipment, and the recording of operating values enables simple diagnostics.

In conjunction with their rugged design, high overload capability and flexible parameterization options, these devices can be individually adapted to motors or motor-gear combinations, as well as to the downstream processes. Grinding, sieving, milling and separating the waste (Fig. 8) make all the difference – these are the elements that ensure a recycling plant for mixed, gypsum-based construction waste (Fig. 9) works efficiently and economically and yields high-quality results. Martin Eves, Carsten Wellhöfer and Christian van der Kamp agree: “As in recycling, getting the desired result in plant engineering often depends on the details – and the new soft starter with Profinet communication is just one such detail.”

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.