GtoG Life + Project: First step towards gypsum circular economy

The European GtoG Project (Gypsum to Gypsum) is a perfect loop and the path to a circular economy: a European collaborative project between the recycling industry, the demolition sector, and the gypsum industry.

1 Background of the GtoG project

The European gypsum industry wishes to promote an increase in the culture of recycling and close the loop for gypsum products and systems within the gypsum industry as well as with the relevant stakeholders in the construction chain. Protecting the natural resources and avoiding an overall negative impact on the environment are key elements of such a culture – well-being, quality and sufficiency for all – within a global economy.

The European gypsum industry is conscious of the challenges which are embedded in the Waste Directive1. Based on its long industrial...

1 Background of the GtoG project

The European gypsum industry wishes to promote an increase in the culture of recycling and close the loop for gypsum products and systems within the gypsum industry as well as with the relevant stakeholders in the construction chain. Protecting the natural resources and avoiding an overall negative impact on the environment are key elements of such a culture – well-being, quality and sufficiency for all – within a global economy.

The European gypsum industry is conscious of the challenges which are embedded in the Waste Directive1. Based on its long industrial experience in sustainable extraction, quarry rehabilitation, biodiversity enhancement, mineral waste reduction, prevention and recycling, the European gypsum industry intends to rationalize even more its efforts in conjunction with the relevant operators in the construction chain to recover construction and demolition (C&D) waste. The industry takes advantage of the eternal recyclability of gypsum to move the construction supply chain towards a positive environmental footprint.

Enhancing the access to natural resources by developing an outstanding construction and demolition waste management will divert C&D waste from landfills by applying the waste hierarchy (prevent-reuse-recycle-recover-dispose) in accordance with the life-cycle impact of gypsum products and systems – from extraction until the end-of-life.

The construction sector represents a strategically important sector for the European Union, providing building and infrastructure on which all sectors of the economy depend. The sector is significant in terms of employment and provides constructed assets representing 49.6 % of the gross fixed capital formation (GFCF).

The construction and demolition waste in Europe is not a European market at all. It has a strong regional orientation. This orientation makes it difficult to obtain solid statistics, let alone to predict a solid forecast of the developments of C&D waste in Europe. The gypsum waste market in the EU is difficult to assess as statistics are lacking and figures are based on rough estimation. The average amount of C&D gypsum based waste is around 2.35 million tonnes per year.

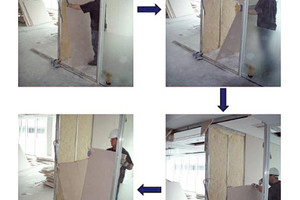

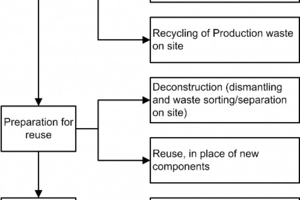

Applying dismantling techniques (Fig. 1) instead of demolishing buildings will lead to the sorting (Fig. 2, 3) and recycling of non-load bearing elements for re-use in the production process. However, as the mineral waste characterization differs, the production processes of the manufacturers must be adapted to increase the recycled content in the product. This needs research and development.

Deconstruction is an essential step in mineral waste recycling feasibility and should become the standard in order to obtain a circular economy. Deconstruction should also be applied in major renovations and light renovations of buildings. Internal partition in an office can be dismantled in case of refurbishment of that office, which is not the case currently. Education of the workforce is essential to create a dismantling mentality when it is easy to be implemented.

Required for optimizing the recyclability of gypsum-based waste:

Promotion of research and development for the design of gypsum products and systems which ensure that recycling is maximized, i.e., that diversion from landfill is taking place effectively;

Promotion of selective deconstruction and sorting among the relevant stakeholders and more particularly the demolition industry;

Promotion of research and development for ensuring the proper recycling of gypsum demolition waste;

Optimization of the internal recycled material input capacity of gypsum manufacturing plants.

2 Vision of the GtoG project

The overall aim of this project is to transform the gypsum demolition waste market to achieve higher recycling rates of gypsum waste, thereby helping to achieve a resource efficient economy (Fig. 4). The market transformation will start happening with the establishment of a collaborative business model between the demolition/processing/manufacturing and recycling industries.

Closed loop recycling for gypsum products will only happen if:

Deconstruction techniques are applied systematically for all demolition and refurbishment projects;

Sorting of mineral waste is done at source – thereby avoiding mixed mineral waste;

Processing is carried out according to clear standards;

Incorporation in the production process is carried out with innovative processes.

Therefore, the GtoG project aims to put in place an integrated approach to holistically manage construction and demolition waste, starting from the major refurbishment/demolition sites to the reinsertion of the recycled gypsum into the manufacturing process via the processing of the gypsum waste as a secondary raw material. This integrated approach uses gypsum products but could be extended, adapted and applied to any other type of construction material used in light-weight construction (Fig. 5, 6).

In order to reach the main goal of the GtoG project, surveys on mineral waste recycling and deconstruction practices and economics were carried out in 2013 in the major European gypsum product consumers, namely in France, Germany, Belgium, the Netherlands, Spain, Greece and Poland. This was necessary due to the strong regional orientation of current practices. Pilot projects implementing the deconstruction techniques, the decontamination, the mineral waste qualification, and the reprocessing in Gypsum manufacturing plants will be carried out in France, the UK, Germany, and Belgium during 2014-2015. The outcomes of these pilot projects will be used to reassess the findings of the surveys carried out in 2013.

The work to be performed includes in summary:

diagnosis of buildings prior to deconstruction;

auditing and the creation of an inventory of recyclable materials;

decontamination of mineral waste if necessary and separation of different mineral waste streams (sorting and segregation);

processing of the gypsum waste received;

qualifying gypsum waste and, finally;

recycling of the mineral waste in plasterboard manufacturing plants (cradle to cradle approach);

establishing the end-of-waste criteria for the recycled gypsum powder (Fig. 7)

3 The partners of the GtoG project

At first, the partners need to consult with their experts in demolition, logistics, and waste management. Involving demolishers is important as they have in-depth knowledge in demolition procedures, regulation and process. Also involved are universities because of their broad knowledge in construction systems, waste specifications and regulations’ framework.

Two additional partners have to be involved: recyclers and plasterboard producers. The first have expertise in designing recycling facilities to comply with high quality specification and they have the skill to manage such facilities. Plasterboard producers are the end of the line, using raw natural gypsum as well as recycled gypsum in the production of new plasterboards or other products. They have expertise in managing different sources of raw materials with high quality standards.

Legal entities are:

Coordinator:

Eurogypsum, The European association of plaster and plasterboard manufacturers

Consultancy:

Recovering SARL- France

Universities:

National Technical University of Athens – Greece

Universidad Politecnica de Madrid – Spain

Fundacion General Universidad Politecnica de Madrid – LOEMCO - Spain

Demolition companies:

Occamat - France

Cantillon Ltd – UK

Recycling assistance BVBA - Belgium

Pinault & Gapaix – France

KS Engineering GmbH – Germany

Recycling companies:

New West Gypsum Recycling Benelux BVBA – Belgium

Gips Recycling Danmark A/S - Denmark

Gypsum manufacturing companies:

Placoplatre SA (groupe Saint-Gobain) - France

Siniat SA – France

Siniat Ltd – UK

Knauf Gips KG – Germany

NV Saint Gobain Construction Products Belgium SA (Gyproc) - Belgium

4 The expected results of the GtoG project

Inventory of current practices for deconstruction, recycling and re-incorporation in the manufacturing process of the recycled gypsum;

European Handbook of best practices for controlled deconstruction of gypsum system;

European Manual of best practices for the audit of building;

European specification/qualifications for recycled gypsum;

Establish the end-of-waste status for recycled gypsum;

Adapt the Green Public procurement wall panels sheet2 providing a 2 % recycled gypsum in the panel;

Assess the optimal European average percentage of recycled gypsum that could be incorporated in the production process aimed at 30 % in the pilot plants;

Assess the carbon footprint of gypsum waste recycling;

Create a culture of deconstruction rather than demolition;

Report on best practices for deconstruction, recycling and re-incorporation in the manufacturing process of the recycled gypsum

5 Findings of the report on current practices on

deconstruction, recycling, and re-incorporation

into the manufacturing process

The report was carried out between January 2013 and September 2013. It covers Austria and Germany, Belgium and the Netherlands, France, Greece, Italy and Spain, Poland, and the UK. The methodology followed was literature review, questionnaires and face to face meetings with the partners and stakeholders involved in the supply chain.

5.1 Types of gypsum waste

We have three categories of gypsum waste based on origin:

Production mineral waste (e.g. gypsum products which do not meet specifications and mineral waste resulting from the manufacturing process)

Construction mineral waste, resulting from construction sites

Demolition waste – the last category includes both demolition and refurbishment waste and is the most complex to address because the mineral waste stream includes other construction materials (such as plasters, paints and screeds etc.).

Recycled with ease means production waste is generally recycled by the factories and used as raw material. Therefore, this measure is waste prevention.

Construction waste collection and recycling has started and is increasing in Scandinavia, France, the UK, and Benelux. However, the re-incorporation rate of the recycled gypsum in the manufacturing process differs from country to country and from plant to plant.

For some reason, far less demolition waste than planned has been recycled: Buildings are currently crushed and not dismantled, thereby impeding the sorting of plasterboard before the building is demolished. Also, plasterboard is a relatively new product used in construction after World War II and we are now only beginning to dismantle buildings with plasterboard linings. Additionally, gypsum demolition waste tends to be contaminated – with screws, vinyl wall paper etc. This renders the treatment more complex at higher costs and limits the ability to use the resulting material.

5.2 Deconstruction current practices

To properly manage C&D waste in the construction industry, a separation and selection of the recyclable mineral waste must be done “in situ”. This practice is even more important when demolishing a building, as it is in the demolition where more C&D waste is generated. The main obstacle facing the selective demolition, today, is the fact that both architects and builders saw their creations as permanent and did not foresee the dismantling at the end of the useful life of the building.

Designing a building in order to ease its assembly must also lead to ease of its disassembly, for future re-uses and recycling. Principles of design for ease of assembly, or ease of construction, should be adapted to become principles of designing for disassembly. The main difference between demolition and deconstruction is that the second one pays special attention to not damage building materials so these can be re-used or recycled in the future.

There are considerable differences between countries which predominately practice demolition and countries which do not. In the countries where deconstruction is a usual practice (the UK, France, Belgium, the Netherlands), gypsum-based waste is generally segregated from the other mineral waste, but in countries where this practice is not usual (Greece, Spain, Poland) plasterboards and gypsum blocks are generally mixed with other construction and demolition waste.

In the countries where deconstruction is the norm (the UK, France, Belgium, and the Netherlands), plasterboard is often stripped out on site by hand. Most of the time the fixing (screws, nails) and undesirable materials (cables, various plastics) are removed on site and the channel is taken off. Wall covering (paper and painting) are left on. It appears that the logistic schemes are complex. They depend in particular on the presence or not of a type of outlet in a certain area.

Legislation does not require traceability of documents; this makes it difficult to establish waste traceability. It is essential to follow waste streams not only from the jobsites to the transfer stations, but also and above all, from the transfer stations to the final outlets. Thus, it is recommended that legislation require traceable documents, as the countries have to monitor qualitatively and quantitatively the rates of construction and demolition waste in order to reach the European objective of a 70 % recovery target.

There is no regulatory requirement when choosing to demolish or to deconstruct buildings in the eight target countries. Some national schemes are starting to promote on site segregation, such as the Royal Decree 105/2008 in Spain that introduced the waste holder obligation to segregate on site different C&D waste fractions if a certain tonnage is exceeded. However, plasterboard waste is not listed and only very large buildings will exceed the specified amount of mineral waste. The regulatory audit of the materials prior to demolition in France is another example of a regulatory requirement which encourages building deconstruction.

The obstacles identified for deconstruction practices today are:

Most of the architects and construction companies do not foresee the dismantling at the end of the useful life of the building.

In countries where demolition is an usual practice, deconstruction is generally perceived as more costly. However, in countries where deconstruction is the common practice, it is generally perceived as a way of optimizing the costs.

5.2.1 Environmental driver

If an evaluation system is followed, environmentally friendly practices are usually carried out. BREEAM3 has been identified as the most used system in the countries under study.

5.2.2 Image of the stakeholder

This driver is closely related with the environmental driver, due to the fact that many companies adopt an environmental approach to spread a good image among the population.

5.2.3 Economical driver

Deconstruction is a way of optimizing costs in countries where the end route for mixed waste is more expensive than for segregated mineral waste. Some interviewees admitted that, if deconstruction is not the most favorable option from an economical point of view, they will not opt for this choice.

5.3 Recycling current practices

The recycling market in Europe is mature in the UK, The Netherlands, Belgium, France and Scandinavia. The average recycling rate for the four countries is 19 %. In the other countries considered in the survey only production mineral waste is recycled, i.e. 5 %. Most of the plasterboard plants (Fig. 8) have simple equipment to crush production waste for its re-incorporation into the manufacturing process.

We have two worldwide leaders – Gypsum Recycling International and New West Gypsum Recycling – and a variety of challengers mainly in the UK and France. Benelux (covering Belgium and the Netherlands), France and the UK have gypsum recycling systems in place. One French gypsum manufacturer operates a recycling facility inside its own plants for C&D waste, combining recycling and manufacturing activities.

The major competitive factors for the recyclers are:

Formulation and technology innovation

Cost effectiveness and pricing

Technical support and service

Alliances with distributors and key end users

The recyclers in the mature market have state of the art technology. They process gypsum and plasterboard waste from construction, renovation, and demolition activities for closed loop (Fig. 9)recycling, i.e. for re-incorporation into the manufacturing process. The core gypsum itself is processed through a series of stages to render it to the manufacturer’s specification. Great care is taken to ensure that physical impurities are removed from the material and the final product is stored in a dedicated location in order to avoid cross-contamination of gypsum powder and paper.

Potential contaminants, apart from mechanical contaminants (screws nails, paints, metals, wood, plastics, etc), reported by the manufacturers and recyclers within the GtoG project are listed below:

Asbestos – some countries require an extensive analysis before any demolition or renovation work. This analysis can be requested by the gypsum recycler.

Vinyl based wall linings have to be separated before the processing because the elasticity of the material makes crushing and tearing difficult .

Glass fiber mesh has to be separated from gypsum mineral waste before the processing.

Lead based paints – the gypsum mineral waste received can require an analysis report confirming that the mineral waste does not contain any lead based paint.

Laminates and insulation material (sandwich panels: polystyrene glued to plasterboard) – they have to be processed by a specialist recycler at a higher cost.

Heavy metals content in the gypsum demolition waste.

5.4 Recycling into the manufacturing process: current practices

The recycling of mineral production waste generated during the manufacturing process in plasterboard manufacturing is important as mineral waste prevention is the priority within the waste hierarchy (Fig. 10). Gypsum production waste can be simply crushed and mechanically sieved for inclusion with natural gypsum sources directly in the manufacturing plant. As the quantity of production waste is small compared to the entire input of raw material (natural and/or FGD gypsum) in many cases it is not necessary to separate paper from the gypsum core.

Re-incorporation needs further research and development when a high percentage of recycled gypsum is re-incorporated in the manufacturing process. Then the purity of the gypsum becomes essential. Recycled gypsum needs further grinding and generally plants are looking for specific grading (particle size). The general practice is to control the paper content amount in the recycled gypsum generally below 1 %.

Higher recycling standards are needed for re-incorporation of recycled gypsum into the plasterboard production exclusively using FGD Gypsum. Intensive sieving is then required to obtain a good grain size comparable to FGD gypsum particle size.

Consistency is closely related to both the supply volumes over time and the quality of recycled gypsum (type, grading, paper content, moisture...). Consistent volume and quality enables a uniform re-incorporation of recycled content in the final board product, effectively promoting an increase in the recycled content without damaging the manufacturing process. An over-supply or under-supply of plasterboard waste process can disrupt the re-incorporation in the manufacturing process, or in the case of over-supply, make it impossible as the plant might not be technically capable of absorbing the recycled gypsum.

Drivers for recycling gypsum waste in different European countries are shown in Table 1.

5.5 Conclusions

A strong cooperation within the supply chain is needed for effective closed loop recycling. For this to happen effectively, there is still a long way to go.

Indeed, the business model differs from country to country according to the culture and environmental legislative framework of that country. However, there are main characteristics which are valid for any kind of C&D waste recycling. The C&D and gypsum based mineral waste recycling systems always involve more than one operator. Each operator has its own responsibility in the economic, technical and environmental efficiency of the recycling of the C&D streams.

Mineral waste collectors can also be recyclers and recyclers can also organize the mineral waste collection. Manufacturers can also be recyclers (having internal recycling facilities) and they can also collect mineral waste. Some gypsum manufacturers have put in place take back schemes for collecting construction waste.

The efficiency of the value chain (Fig. 11) also depends on the monetary value of the recycled C&D gypsum waste: metal has infinite value and is thus recycled. Plasterboard is a commodity and has little monetary value for the waste collectors, the demolishers or the contractors.

The sorting at demolition and construction sites will happen for plasterboard if:

National authorities push for the dismantling, recycling or recovering of the plasterboard waste – by giving a positive legal context and appropriate incentives even more so when the recycling market is not mature;

other types of mineral waste of high monetary value are recovered at the same time;

Audit of gypsum-based waste is done prior to demolition;

Logistics are optimized.

Otherwise, the landfill route will still be seen as the easiest and often most economically viable route.

6 Next steps

Pilot projects will be carried out in Belgium, UK, France (2) and Germany. In each country, deconstruction will take place in a running dismantling project. The plasterboard waste will be transferred to the recyclers who will process it and transfer the recycled powder to the five manufacturers’ plants to be re-incorporated in the production process. Gypsum specifications will be drawn upon the trial’s results in all of the manufacturers’ plants, comparing them to the specifications already achieved in those countries.

Economic, environmental, and social indicators will be used to measure each step of the chain (deconstruction-recycling and re-incorporation).

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.