Key factors to minimise emissions from parallel flow regenerative lime kilns

Emission reduction is a significant topic in the lime industry. This article concentrates on NOx formation in PFR lime kilns, as these kilns provide the highest thermal efficiency of all kiln types. It goes on to share with its readers the conclusions drawn from years of research and development by Maerz Ofenbau AG, on how to reduce NOx formation, thereby minimising emissions and contributing to a healthier environment.

1 Introduction

Directive 2010/75/EU of the European Parliament, adopted on November 24th, 2010, lays down rules for EU member states on the integrated prevention and control of pollution arising from industrial activities. Member states are obliged to take the necessary measures to ensure that no installation, in this case no lime kiln, is operated without a permit. Germany incorporated the IED (Industrial Emissions Directive) 2010/75/EU into national law (BlmSchG) in May 2013. Other EU member states have reached an equivalent status and are currently implementing the IED into their respective...

1 Introduction

Directive 2010/75/EU of the European Parliament, adopted on November 24th, 2010, lays down rules for EU member states on the integrated prevention and control of pollution arising from industrial activities. Member states are obliged to take the necessary measures to ensure that no installation, in this case no lime kiln, is operated without a permit. Germany incorporated the IED (Industrial Emissions Directive) 2010/75/EU into national law (BlmSchG) in May 2013. Other EU member states have reached an equivalent status and are currently implementing the IED into their respective national laws.

Under the IED the European commission established the BAT (best available technology) conclusions 2013/163/EU for the cement and lime industry in April 2013 as successor to the IPPC directive. The BAT Conclusion 2013/163/EU provides guidelines not only for emission limits but also for primary and secondary emission reduction techniques. With the implementation of the IED into national law, the binding effect of the BAT conclusions has increased considerably. Kiln manufacturers are expected to provide kiln designs and operational procedures to adhere to or to exceed the legal minimum requirements.

Worldwide more quicklime is produced in Parallel Flow Regenerative (PFR) lime kilns than in any other kiln type thanks to their unmatched thermal efficiency. As NOx is not only a dangerous pollutant, but also an important indicator for the quality of the combustion process, the following paper focuses on the formation of NOx in PFR lime kilns and the resulting emissions thereof using different fuels.

On the one hand, this paper covers facts about NOx emissions from PFR lime kilns fired with different fuels, depending on fuel properties, required burning temperatures, temperature profiles, temperatures at the burner tip and the influence of excess air.

On the other hand, emphasis is placed on primary techniques to reduce NOx formation in PFR kilns. Although secondary techniques for NOx reduction are also mentioned in this publication, they are not examined in depth as their use is not justified for PFR lime kilns producing soft burnt lime. The need for secondary reduction techniques for kilns producing hard burnt lime at very high burning temperatures has not yet been proved and would go beyond the scope of this publication.

Years of data collection, research and development by Maerz Ofenbau AG offers every customer access to the latest state-of-the-art technology and operational support, thus minimising emissions wherever possible by means of primary emission reduction techniques as detailed in this paper.

2 BAT associated emission levels for NOx from flue

gases of kiln firing processes in the lime industry

The following limits are an extract from the BAT Conclusion 2013/163/EU:

At first glance the range of the AEL (average emission level) leaves ample room for interpretation and in future could be a challenge for the plant operators to obtain appropriate limits for their permits. In new EU member states, representatives of the authorities might have difficulties in stipulating practicable emission limits.

3 Primary and secondary techniques in order to

reduce NOx emissions according to BAT

The BAT not only states emission limits as given in the table above, but also provides examples for primary and secondary techniques to reduce emissions. Primary techniques aim at effectively avoiding or reducing emissions by kiln design and operational parameters. Secondary techniques concentrate on the reduction of emissions in the flue gases.

3.1 Primary techniques: Fuel selection

The following primary techniques must be considered for lime kilns (direct quote from BAT Conclusion 2013/163/EU):

Fuels causing lower emissions, like natural gas, diesel oil or lignite, are not always available and even if they are available, lime producers are, for economic reasons, often forced to use other fuels like petroleum coke or coal. Moreover, this economic evaluation may vary due to fluctuations in energy prices. Fuel flexibility is therefore vital and requires multiple firing systems, as well as lime kilns capable of utilising a variety of different fuels.

The application of BAT 45 (a)I requires actions from both lime producers as well as kiln manufacturers. An adapted fuel purchasing strategy combined with additional investments for fuel storage and handling systems are some of the most important measures to be considered by the lime producers. Lime kiln manufacturers therefore have to provide a wide range of improved lime burning technology, ensuring minimum losses in kiln performance and lime quality.

3.2 Primary techniques: Process optimization

Primary emission reduction techniques, according to BAT 45 (a)II, are of utmost importance to the lime industry due to the high potential for process improvement. As the PFR lime kiln provides the highest thermal efficiency of all lime kiln types, this paper focuses on primary emission reduction techniques for PFR lime kilns.

3.3 Secondary techniques

In addition to the primary techniques the following secondary techniques will be discussed briefly:

Initial experiments with Selective Non-Catalytic Reduction (SNCR) on PFR lime kilns were stopped at an early stage because of:

Optimisation of the burning process and subsequent adherence to thresholds

Virtually no demand for this process from the lime industry

Inadequate research of this technique for PFR lime kilns

Additional investment and operating costs necessary

NH3-slip to be monitored permanently

Unknown influence on the service life of equipment

Selective-Catalytic Reduction (SCR) is not appli-cable for use with PFR lime kilns because:

Off-gas temperatures are too low

Periodic temperature variations of the kiln off-gases

It should however be mentioned, that emissions from single shaft kilns operating at very high temperatures are currently being investigated. If the upper NOx-limit of 500 mg/Nm³ cannot be adhered to, Elex CemCat AG, a sister company of Maerz Ofenbau AG, can provide a simple “High Dust” SCR system with the following characteristics:

Min. 75 % NOx reduction

Min. 75 % VOC reduction

Up to 30 % SO2 reduction

4 Consequences of the BAT regulations

for the lime industry

As the thermochemical processes in shaft kilns of large dimensions are not directly observable, extensive research is necessary to better understand the physical and chemical interrelationships. This is a prerequisite for the implementation of and compliance with BAT 45 (a)II.

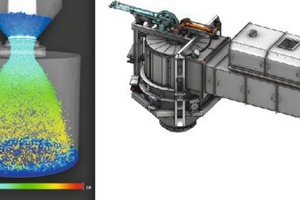

Improvements in the fields of pyroprocessing and lime kiln design require a profound understanding of the combustion process taking place inside lime kilns and inside the material bed of shaft kilns. Large scale measurement campaigns are essential; with good cooperation between kiln manu-facturers and plant operators as a precondition. In addition, real kiln models as well as computer models for the bulk movement, the thermochemical process and the fluid dynamics, are essential to optimise lime shaft kiln and firing system designs.

Investigations and measurements on existing PFR kilns have confirmed computer simulations in pointing out the uniform distribution of heat over the cross-section as well as along the shaft axis as the key factor to reducing emissions without further consideration of fuel properties such as the nitrogen content of solid fuels. Conversely, a uniform heat distribution depends on fuel and combustion air distribution, with the combustion air distribution depending on the grain size distribution of the limestone in the kiln shaft.

This understanding leads to the main task definition for the primary emission reduction techniques:

Lime shaft kilns and firing systems must be designed to achieve uniform heat distribution over the cross-section and along the kiln axis.

Lime shaft kilns and firing systems must be operated with the help of process control systems with implemented appropriate algorithms, in order to achieve uniform heat distribution.

5 NOx emissions from PFR lime kilns

This chapter highlights some characteristics of PFR kilns in connection with NOx emissions from PFR lime kilns. Table 1 shows emissions from circular Maerz lime shaft kilns stated as NO2 based on 11 % O2. When comparing the emissions from different kilns with differences in cross-sections, number of burner lances as well as operating parameters, fired with different fuels, it must be considered that the thermal load related to one single burner lance as well as the excess air and the air supplied through the burner lances influences the NOx emission.

Therefore, a conclusive dependence of the NOx emission on the nitrogen content of the fuel could not be found. Nevertheless the nitrogen content of the fuel must be considered as an important factor.

As kilns using solid fuels showed the highest NOx emissions, the nitrogen contents of different solid fuel samples were determined first as listed in Table 2.

The nitrogen content of solid fuels is important in connection with the NOx emissions because of the following well known facts regarding NOx formation:

Fuel NOx is generated at T > 800 °C, conversion rate from coal ≈ 20 % to 40 %

Thermal NOx is formed at T > 1000 °C; the formation rate increases exponentially with temperature

NOx formation is strongly promoted in the presence of an excess of air

5.1 Where in the PFR lime kiln is NOx formed?

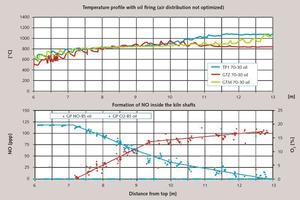

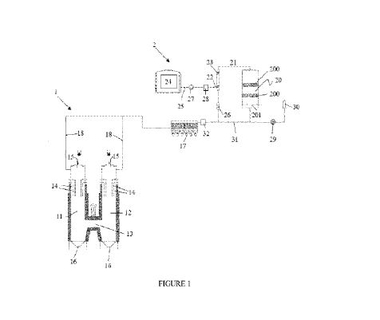

In order to better understand the burning process inside the material bed of PFR lime kilns the generated NOx was measured by means of long gas extraction pipes running down with the kiln feed, together with thermocouples. The upper graph of Figure 1 shows the temperature profile of an oil- fired PFR lime kiln, whereas the lower graph shows the oxygen and the NOx contents of the combustion gas.

The temperature profile shows a gentle temperature rise in the burning zone. Nevertheless 75 % of the NOx-formation takes place within the first third, and only 25 % in the rest of the burning zone. This could be an indication, that mainly fuel NOx is generated because the formation of thermal NOx takes place at higher temperatures.

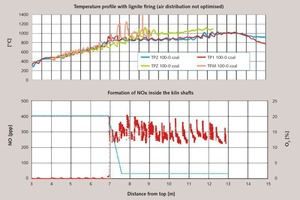

The upper graph of Figure 2 shows the temperature profile of a lignite-fired circular PFR lime kiln, whereas the lower graph shows the oxygen and the NOx levels of the combustion gas.

The temperature profile shows a sharp temperature rise just underneath the burner lance tips, which indicates an immediate ignition of the lignite underneath the burner lances. This phenomenon can be explained by the low ignition temperature of lignite, as well as by the presence of sufficient oxygen delivered with the pulverised fuel conveying air through the burner lances. 100 % of the NOx-formation takes place in a very short zone directly underneath the burner lances. A reduction of the NOx-formation can only be achieved with a higher number of burner lances and less coal conveying air.

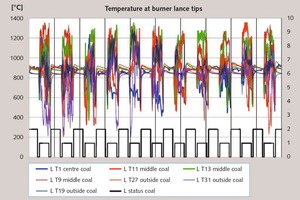

Temperature measurements at the burner lance tips have confirmed these peaks (as may be seen in Fig. 3), where hot spots of up to 1300 °C are present with lignite firing. These hot spots generate more NOx and should be reduced as far as possible. Such hot spots can also be observed when using hard coal or wood dust. Hard coal with a high swelling index shows the highest peaks, whereas petroleum coke behaves completely differently, as it does not ignite directly underneath the burner lances.

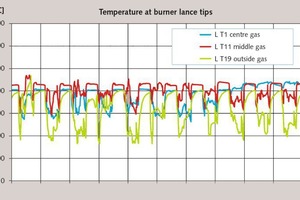

No hot spots at all underneath the burner lances were detected with natural gas firing (see Fig. 4).

6 Application of primary techniques

for PFR lime kilns

6.1 Influence of burning temperatures

and temperature profiles

6.1.1 Burning temperature and reactivity

of burnt lime

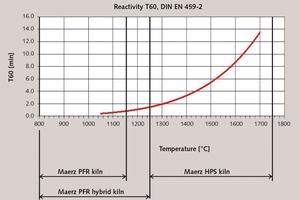

The lime industry needs different types of lime kilns to produce lime with the required reactivity. The reactivity of the burnt lime depends mainly on the burning temperature; the retention time in the kiln only plays a secondary role. It must be stated that the laboratory results shown in Figure 5 are related to one specific granular crystalline limestone sample with very high CaCO3 content. As limestone varies from source to source, this curve can vary in a wide range for limestone from other sources.

When lime with high reactivity is needed, the PFR lime kiln is the ideal choice. Well-designed PFR lime kilns operate at an average burning temperature of 950 °C with peaks up to 1050 °C. For slightly harder burnt lime special PFR hybrid kilns with additional side burners are available. Such kilns can be operated with burning temperatures of up to 1250 °C. For the production of aerated concrete, hard burnt lime with low reactivity is required. Counter-stream-fired Maerz single shaft kilns provide the necessary burning temperature for this application.

As previously mentioned, the formation of thermal NOx increases exponentially with the burning temperature, so that higher NOx emissions from kilns producing hard burnt lime have to be expected.

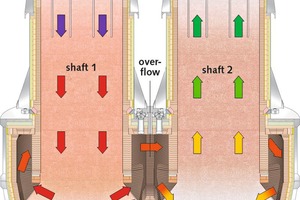

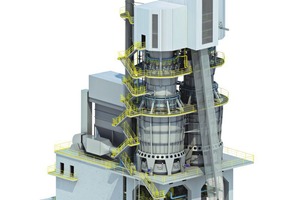

6.1.2 Circular Maerz PFR lime kilns

Lime shaft kilns have to be designed for a uniform heat distribution over the cross-section of the shafts and along the kiln axis. Besides other measures, it has been proved that the best precondition to achieving this objective is the use of circular kiln shafts combined with circular gas channels as shown in Figure 6. Other PFR kiln designs are less effective, as a result of their asymmetrical design and uneven gas flow distribution, resulting in uneven heat distribution with the disadvantage of higher emissions. Asymmetrical PFR kilns with direct cross-over channels or PFR kilns with poorly designed circular gas channels have no or only limited potential for the application of primary techniques to reduce emissions.

6.1.3 Heat distribution and temperature profiles

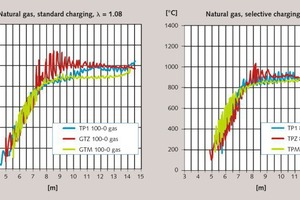

Figure 7 shows the measuring results at one and the same circular PFR kiln fired with natural gas. The red curves represent the temperature profile in the shaft centre, the green curves show the temperature profile near the refractory lining, and the blue curves show the temperature profile halfway between the centre and the wall. The horizontal axis shows the distance from the kiln top and the vertical axis shows the temperature.

The chart on the left, in comparison with the chart on the right, shows higher temperature peaks in the centre, arising from too much air in the centre. The fuel distribution was the same in both cases. A better air distribution controlled by targeted, selective limestone charging as described later in this paper, resulted in an improved temperature distribution across the shaft cross-section and along the shaft axis. Peak temperatures in the centre were also reduced and the NOx emission was reduced from 30 to 25 mg/Nm³.

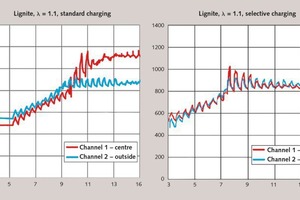

Figure 8 shows the measuring results from the same PFR kiln, fired with lignite. The red curves represent the temperature profile in the shaft centre; the blue curves show the temperature profile near the refractory lining.

The chart on the left, in comparison with the chart on the right, shows higher temperatures in the centre arising from too much air in the centre. The fuel distribution was again the same in both cases. The better air distribution controlled by targeted, selective limestone charging improved the temperature profile and reduced the NOx emission from 100 to 75 mg/Nm³.

6.2 Optimized combustion over the length

of the burning zone

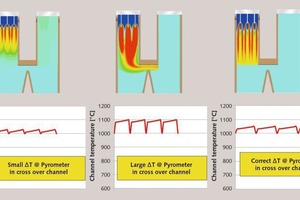

Reduced NOx-formation can be achieved by optimising the excess air factor setting. An optical pyrometer in the cross-over channel provides all the information required: the ∆T measured by the pyrometer between the beginning and the end of each burning cycle can be maintained at a constant level by the kiln operator or by a new process management system patented by Maerz.

The flame length can be adjusted by the amount of excess air dependant on the pyrometer’s measurements. Figure 9 shows from left to right:

Excess air factor too high resulting in hotter flame, lower channel temperature, less ∆T at the pyrometer and more NOx

Excess air factor too low with incomplete combustion in the burning zone, post-combustion in the cooling zone and in the gas channels, high channel temperature, more ∆T at the pyrometer and more NOx

Correct excess air factor, best temperature profile along the burning zone, less NOx.

A precondition for successful utilisation of this process control system is to maintain the heat distribution over the cross-section of the shaft as constant as possible. This not only requires a sophisticated fuel distribution system, but also a uniform and symmetrical air and hot gas distribution, which is facilitated by circular Maerz PFR kilns with circular gas channels.

6.3 Optimized combustion over the cross-section of the burning zone

Uniform fuel distribution is state of the art but insufficient by itself to achieve perfect temperature distribution over the cross-section of the burning zone. The solution is to charge the limestone selectively in order to control the combustion airflow over the cross-section of the burning zone. Different grain size mixtures are charged to the centre and to the outside of the shafts.

A circular PFR lime kiln according to Figure 6, is the pre-condition for this application. Figure 10 shows the latest design for such a kiln charging system.

7 Summary and outlook

The Industrial Emission Directive 2010/75EU and the BAT Conclusions 2013/163/EU are or will be implemented into national law in all member states of the European Union. In order to comply with these regulations, lime producers and lime kiln manufacturers are required to take appropriate measures. The regulations not only stipulate emission limits but also primary and secondary techniques in order to reduce pollutant emissions.

NOx formation in circular Maerz PFR lime kilns can be reduced by means of primary techniques according to BAT 45 (a)II. Table 3 shows deviations, leading to increased NOx formation, and their causes as well as applicable primary techniques to reduce NOx emissions. Some of the techniques shown are already well known and state of the art, but others are new and were developed during recent years. The development of new primary techniques as described below is based on comprehensive measurements and supplementary computer simulations.

Years of data collection, research and development by Maerz Ofenbau AG have provided the basis for improvements of lime shaft kilns and the development of primary techniques which are fully compliant with the valid regulations. All circular Maerz PFR lime shaft kilns together with their firing systems for all different types of fuel represent the latest state of the art and surpass all legal requirements.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.