Technology improvement of production of sulfuric acid integrated with cement from phosphogypsum

The improved drying and calcination process with a vertical drying dehydration device was proposed for the production of sulfuric acid integrated with cement from phosphogypsum, aiming at increasing the SO2 concentration in the flue gas and reducing the system heat consumption. The improved process has been applied in the design of a practical project in Ningxia (China) and is expected to be put into operation in 2016. The design of refractory materials for the pyroprocessing system was discussed. The feasibility analysis of the New Suspension Preheater (NSP) used in decomposition of gypsum has been carried out.

1 Introduction

Phosphogypsum is a kind of solid waste produced by wet-process phosphoric acid production, with annual emissions of more than 100 million tons worldwide and 50 million tons in China, respectively. The stacking of phosphogypsum leads to many problems such as taking up lots of land resources, polluting the air, water and soil, and increasing the high costs of construction and maintenance of the phosphogypsum stack. At present, about 10 % of the total phosphogypsum are used as a resource in China. For a long time, the utilization of phosphogypsum has been listed by the Chinese...

1 Introduction

Phosphogypsum is a kind of solid waste produced by wet-process phosphoric acid production, with annual emissions of more than 100 million tons worldwide and 50 million tons in China, respectively. The stacking of phosphogypsum leads to many problems such as taking up lots of land resources, polluting the air, water and soil, and increasing the high costs of construction and maintenance of the phosphogypsum stack. At present, about 10 % of the total phosphogypsum are used as a resource in China. For a long time, the utilization of phosphogypsum has been listed by the Chinese government as one of the four major environmental protection projects. In China, phosphogypsum is mainly used for the production of sulfuric acid (SA) integrated with cement, cementitious materials, phosphogypsum standard bricks, potassium sulfate by a two-step conversion.

The technology of production of SA integrated with cement from phosphogypsum was proposed firstly by Britain, Austria, the former East Germany, etc. in the early 1960s due to the sulfur shortage on the world market. One of the most successful processes is the OSW-Krupp technology invented by the Linz Chemie AG in Linz, Austria which was put into operation in 1969 (240 t/d), and a 350 t/d production line in Africa was put into operation with the same technology in 1972. The key to this technology is to ensure the normal operation of the kiln to obtain the flue gas with high concentration SO2 and the high quality clinker. In China, studies on this technology began in the 1950s.

The “Three-Four-Six” project in the Lubei enterprise group was put into operation in 1990, that is, producing 40000 t of SA and 60000 t of cement, respectively annually with phospho- gypsum produced by an ammonium phosphate plant with an annual production of 30000 t. The technology used was similar to the OSW-Krupp process. At present, the Lubei enterprise group has achieved an annual production of 0.15 mta ammonium phosphate, 0.20 mta SA and 0.30 mta cement, becoming the largest producer in the world in the production of SA integrated with cement from phosphogypsum.

2 Technology status

At present, the SP kiln process is the most advanced technology, preferably used with the advantage of higher unit volume production, lower heat consumption and absolute value of 1 ~ 2 % higher SO2 concentration in the flue gas, compared with long dry kiln and shaft preheater kiln processes. However, because of the existing coke in the raw meal, the gas temperatures at the preheater outlet and in the kiln chamber plus the temperature of the raw meal entering the kiln should be controlled properly, due to equipment erosion when the gas temperature is lower than the acid dew point at the preheater outlet. There, coke combustion in the raw meal and local buildups jam in a specific position of the preheater system can occur.

2.1 Raw meal preparation

Generally, three ingredients are used at the stage of the raw meal preparation, that is phosphogypsum, clay and coke, with proportions of 85 ~ 86 %, 7 ~ 8 % and 6 ~ 7 % respectively. The phospho-gypsum should be dried separately to decrease the moisture from 40 % to less than 15 %. Then the phosphogypsum is mixed with clay and coke, and fed to the drying and milling system. The required fineness is less than 12 % based on 80 μm sieve residue.

The degree of CaSO4 decomposition is affected directly by the amount of coke in the raw meal. If the C content is high, a large amount of one step decomposition reaction will occur, which will lead to many problems, such as obtaining more CaS plus a decrease in the production of C3 S and a lower SO2 concentration. But if the C content is low, the CaSO4 will not be decomposed completely which also leads to lower SO2 concentration. In addition, the raw meal will easily form unwanted ring deposits in the kiln, affecting the rate of operation. According to the reaction equations, the theoretical mole ratio of C to SO3 is 0.5. But the C content is a little higher than the theoretical value considering the loss caused by combustion.

2.2 Decomposition and calcination

The key equipment in such a process is the kiln. With the SP kiln technology, the multi-stage suspension preheaters coupled with the kiln have been adopted as the decomposition and calcination system. The high-sulphur coal, in which the S content is more than 2.5 %, is recommended here which can increase the SO2 concentration in the flue gas as well as reduce the operation cost.

The SO2 gas generated in the kiln enters the multi-stage suspension preheaters and is discharged from the top stage preheater after multi-stage heat exchanging with raw meal. Then the SO2 containing flue gas is introduced into the SA system through the electric precipitator by the exhaust fan. Generally, the control indexes for the clinker are as follows: KH is 0.84 ± 0.02, SM is 3.4 ± 0.2, AM is 2.0 ± 0.2. Other requirements include CaS < 2 %, SO3 < 2 %, f-CaO < 2 % and MgO < 2 %.

Both the processes of SO2 generation and clinker formation occur in the kiln. To ensure the concentration of SO2 in the flue gas according to the requirement of SA production and the quality of the clinker, many measures should be taken into account, such as the control of the raw meal proportion and the regulation of the kiln atmosphere. If there exists a strong reducing atmosphere in the kiln and excess C in the raw meal, it may lead to the formation of elemental sulfur which can block part of the equipment in the SA production system. In addition, if the C content in the raw meal is low and there exists a strong oxidizing atmosphere, it is prone to the formation of low-melting material and unwanted kiln shell deposits. The O2 concentration at the inlet of the kiln should be controlled in the range of 0.5 ~ 1.5 %.

2.3 SA production

The section of flue gas purification: the low temperature flue gas discharged from the preheater system is purified through the retention tower, scrubbing column and wet precipitator to remove the raw meal and acid fog. The settling sludge and dilute acid are treated to form CaSO4 for recovery. Because the gypsum is slightly soluble in water, special attention should be paid to fouling in the process which can cause blockages. The CO concentration should also be strictly controlled so as not to cause an explosion.

The section of drying and absorption and conversion: the clean gas from the purification section enters the drying tower removing the moisture, and then goes into the converter in which the SO3 is generated by the reaction between SO2 and O2. After that, it enters the absorption tower to produce the SA product. The low temperature waste heat recovery and low resistance and high efficiency double transformation and double absorption process have been adopted. The main indexes in this section are as follows: SO2 concentration entering the converter is 5.5 ~ 7.5 %, acid frog is less than 0.03 mg/Nm³, dust concentration is less than 0.039 mg/Nm³, the rate of conversion of SO2 is more than 99.56 % and total rate of absorption is more than 99.97 %.

3 Technology improvement of production of SA

integrated with cement from phosphogypsum

In 2012, the improved technology of production of SA integrated with cement from phosphogypsum was proposed considering the characteristics and deficiency of the existing technology, on the basis of actual site investigation and technology status analysis. And a design and construction contract has been successfully signed with the Ningxia Tianyuan Manganese Company Limited which is the largest manganese manufacturer in the world. This production line is expected to be put into operation in 2016 and annual production of SA and clinker will be 300000 tons, respectively.

3.1 Technology improvement of gypsum drying and cement calcination

At present, there are still a lot of problems in the existing technology. They are as follows:

Low capacity and high energy consumption. The heat consumption is generally above 1450 kcal/kg (the heat consumption during the drying process and the consumption of coke are excluded).

Low SO2 concentration in the flue gas. It is generally only 8 ~ 9 % which may lead to larger equipment specifications and higher investment costs in the SA production system.

Buildups at a specific position of the preheater system caused by combustion of coke.

The liquid phase occurs in the kiln while CaSO4 is not decomposed completely, which results in a low decomposition rate of gypsum because of the liquid phase coating and affects the clinker quality.

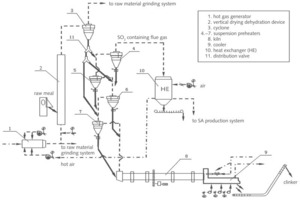

Considering the above problems mentioned in the existing technology, a newly developed drying and calcination process has been proposed as shown in Figure 1. The system mainly includes the hot gas generator, vertical drying dehydration device, 4-stage suspension preheater, kiln, cooler, etc. The characteristics of this process is that the drying and dehydration process of the gypsum is carried out in a separate vertical drying dehydration device, so the flue gas generated by vapor and the high temperature heating source in the process of drying dehydration is independent of the flue gas from the calcination system. The result is that it can increase the SO2 concentration in the flue gas while reducing the amount of ineffective exhaust gas.

Higher SO2 concentration in the flue gas can create beneficial conditions for the downstream process of SA production. Furthermore, the vapor generated from the dehydration process is not mixed with the SO2 containing flue gas which can reduce the risk of corrosion of the equipment. The raw meal is fed into a vertical drying dehydration device in which the process of drying and dehydration occurs. The heat source is hot exhaust gas produced by a hot gas generator (or other heat sources). The crystal water existing in the phosphogypsum can be released completely. The dust containing exhaust gas discharged from the drying dehydration device is introduced to a cyclone to separate the raw meal from the exhaust gas. According to different conditions of system operation, the high temperature raw meal can be fed into different positions of the preheater system through distribution valves. As a result, the temperature of the SO2 containing flue gas at the top preheater outlet and the temperature of the raw meal discharged by the bottom preheater can be controlled, avoiding the combustion of coke in the preheater system.

Then the processes of heat transfer, decomposition, calcination and cooling occur. The dust excluded exhaust gas generated from the drying hydration device can be introduced to the milling system to dry the raw meal for heat recovery. A heat exchanger is equipped in the pipe coupled with the top preheater. The heat can be recovered from the SO2 containing flue gas on the premise of non occurring acid dewing issues in the follow-up equipment. The heat recovered can be used for air heating. The heated air can be used as combustion air of the hot gas generator. The thermal efficiency of the whole system can be maximized.

In order to realize the newly developed drying and calcination process as shown in Figure 1, the key is to develop the vertical drying dehydration device in which the physical water and crystal water can be released completely. Researches [1-3] show that, the process of dehydration of the gypsum can be divided into the following two steps:

CaSO4 ∙ 2 H2O → CaSO4 ∙ 0.5 H2O + 1.5 H2O↑⇥(1)

CaSO4 ∙ 0.5 H2O → CaSO4 + 0.5 H2O↑⇥(2)

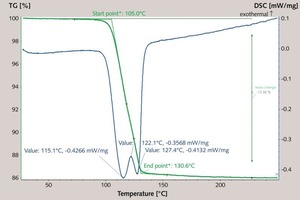

The first step generally occurs at 105 ~ 150 °C, and the second step generally occurs at 150~200 °C. So the temperature of the exhaust gas from the vertical drying dehydration device should be controlled at about 210 °C. And it should ensure enough retention time of the raw meal in the vertical drying dehydration device. Figure 2 shows the TG-DSC curve of one kind of phosphogypsum. It shows that the first step in the dehydration process of such phosphogypsum finishes at about 130 °C. The mass change of the second step is too small to be investigated.

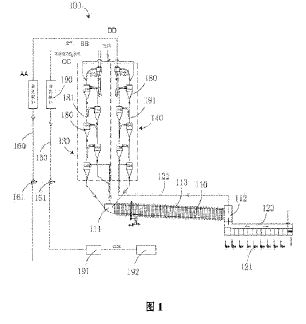

Based on the newly developed drying and calcination process, the vertical spouted-type drying dehydration device has been developed. It is a suspended drying dehydration device with multiple throats designed to provide a multi-stage spouting effect. The advantages are that it can increase the retention time ratio of solid to gas, which results in a longer retention time of raw meal in the device, so enhancing the gas-solid heat transfer.

The temperature of the exhaust gas from the vertical drying dehydration device should be controlled at above 210 °C to ensure that the physical and crystal water in the raw meal is released completely. This can be realized by the adjustment of the heat from the hot gas generator with fixed raw meal feeding. Based on the above described concept, a patent entitled “A kind of energy-saving drying and calcination equipment that can increase the SO2 concentration” has been applied for China, and the patent authorization has been granted (Patent No. ZL 201320230168.2).

In 2012, a design and construction contract was successfully signed with the Ningxia Tianyuan Manganese Company Limited with a design capacity of clinker and SA of 950 t/d and 1000 t/d, respectively. It is nearly three times the maximum capacity of the existing line. The kiln length is 100 m at a diameter of 5.2 m, and the newly developed drying and calcination process mentioned above has been adopted. Now the production line is under construction. It is expected to be put into operation in 2016.

3.2 Optimal configuration of refractory materials

It is known that the SO2 concentration in the flue gas is high in the pyroprocessing system in the production of SA integrated with cement from phosphogypsum. In order to prevent the system corrosion caused by SO2, the design of corrosion resistance should be specially considered during the configuration of the refractory materials.

Considering the low rotary speed (the designed value is about 2.5 rpm generally) in such a production line, the composite high aluminum brick can be adopted in the decomposition zone and safety zone of the kiln to decrease the surface temperature of the kiln, thus resulting in lower heat loss. At the same time, the composite high aluminum brick with low Fe2O3 should be recommended to prevent carbon deposits in the brick structure. More carbon deposits will occur and lead to the formation of strong whiskers while iron exists as a catalyst. This will destroy the refractory structure.

During masonry of the kiln, a larger ISO brick should be adopted in each zone of the kiln to decrease the brick joints, and fire mortar should be used. In addition, the thin steel plate as the lining can also be used during masonry. It means that the thin steel plate layer is located between the brick and kiln shell to prevent the flue gas from corroding the kiln directly.

For the static equipment in the pyroprocessing system, it should minimize the use of calcium silicate board. Three layers of composite masonry should be used, that is calcium silicate board + light heat insulation brick or insulation castable + working lining. The castable with good air tightness should be used. The refractory material near the brick support should not use brick but the castable with a ring of G type brick at the lower end of the castable. The expansion joints should be designed rationally and Z type expansion joints are recommended to increase the air tightness of the lining structure.

3.3 Feasibility analysis of the New Suspension Preheater (NSP) used in decomposition of gypsum

Since the 1960s, the suspended devices for decomposition of gypsum have begun to be developed by some researchers in Germany and the USA. In recent years, researchers from the Kunming University of Science and Technology and other domestic universities have done some researches on NSP technology used in the decomposition of phosphogypsum, but with no substantive breakthrough.

Firstly we carry out the feasibility analysis of NSP used in the decomposition of gypsum based on the reaction mechanism. The solid-solid reaction is hard to carry out at a suspended condition with carbon as the reducing agent. Moreover, the gas-solid reaction occurs more easily with CO gas as the reducing agent. Considering the following reactions:

CaSO4 + 4 CO → CaS + 4 CO2 ∆rHU298

= –180.21 kJ/mol⇥(3)

The above reaction is an exothermic reaction. The second step reaction may occur between CaS produced by the first step and the remaining CaSO4:

3 CaSO4 + CaS → 4 CaO + 4 SO2 (> 1000°C) ∆rHU298

= 1057.05 kJ/mol⇥(4)

the overall chemical reaction is:

CaSO4 + CO → CaO + SO2 + CO2 (> 1000°C) ∆rHU298

= 219.21 kJ/mol⇥(5)

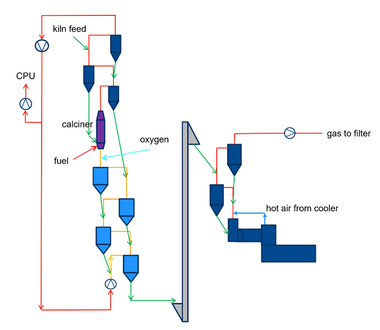

Based on the above analysis, we consider that the first step reaction can be carried out outside the kiln the length of which can be shortened. A reducing furnace can be equipped in which the first step reaction occurs and CaS is produced with CO as the reducing agent. The raw meal and exhaust gas mixed in the flue gas from the reducing furnace can be separated by the cyclone.

The raw meal enters the kiln and the second step reaction occurs. The high temperature exhaust gas can provide heat for the dehydration of phosphogypsum. The advantage is that the reducing agent need not be mixed with raw ingredients avoiding the combustion issues in the preheater system. And the 5- or 6-stage preheaters can be used to obtain a better preheating effect.

CO2 produced by the reaction between CaSO4 and the reducing agent and the combustion of excess reducing agent can be independent of the flue gas from the kiln. So the SO2 concentration can be increased (above 12 % at dry basis). It can create beneficial conditions for the follow-up process of SA production reducing the investment. At present, the industrial test based on such technology has been prepared. The second step reaction still occurs in the kiln, and the heat required in the kiln will not be much decreased.

In addition, the gaseous sulfur as the reducing agent has also been considered. CaS is produced by the first step reaction between CaSO4 and S. Using S as the reducing agent, the reactions are as follows:

S + O2 → SO2 (> 250°C) ∆rHU298 = -296.83 kJ/mol⇥(6)

CaSO4 + 2 S → CaS + 2 SO2 (750 ~ 1000°C) ∆rHU298

= 358.05 kJ/mol⇥(7)

3 CaSO4 + CaS → 4 CaO + 2 SO2 (> 1000°C) ∆rHU298

= 1057.05 kJ/mol ⇥(8)

the overall chemical reaction is:

2 CaSO4 + S → 2 CaO + 3 SO2 ∆rHU298 = 707.55 kJ/mol⇥(9)

The concept is similar to that of using CO as the reducing agent with the advantage of increasing the SO2 concentration in the flue gas, but the cost of S is higher.

4 Conclusions

After decades of development, the technology of the production of SA integrated with cement from phosphogypsum has made great progress. The technology can solve the problem of sulfur resource shortage decreasing the cost of SA, as well as realize the resource utilization of a lot of industrial gypsum. At the same time, it can deal with many environmental problems caused by the stacking of phosphogypsum. It can also reduce the demand for limestone in the cement industry so as to reduce carbon emissions. The improved technology introduced herein could obtain optimized technical indexes. This newly developed technology shows a promising prospect for commercial production.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.