SO2 emissions and reduction technologies in the Chinese cement industry

Facing more and more strict and detailed environmental protection standards, Chinese cement enterprises have to adopt various desulfurization technologies. The authors analyze the cycle processes of sulfur in the cement production process, and introduce various desulfurization technologies currently used in China’s cement plants.

In 2020, there were 1609 dry process cement clinker lines in China, with an annual cement output of 2.395 billion t, accounting for 58% of the global output. In 2018, the Chinese cement industry emitted 700 thousand t of SO2, accounting for 2-2.5% of Chinese total industrial SO2 emissions [1, 2]. At present, the cement industry has become one of the most serious emission sources and key control industries in China’s industry [3].

1 Emission standard of sulfur dioxide for the Chinese cement industry

At present, the current SO2 emission standard of the Chinese cement industry is the Emission...

In 2020, there were 1609 dry process cement clinker lines in China, with an annual cement output of 2.395 billion t, accounting for 58% of the global output. In 2018, the Chinese cement industry emitted 700 thousand t of SO2, accounting for 2-2.5% of Chinese total industrial SO2 emissions [1, 2]. At present, the cement industry has become one of the most serious emission sources and key control industries in China’s industry [3].

1 Emission standard of sulfur dioxide for the Chinese cement industry

At present, the current SO2 emission standard of the Chinese cement industry is the Emission Standard of Air Pollutants for the Cement Industry (GB4915-2013), and the limit value of SO2 emission concentration is 100 mg/m3 (the converted concentrations of Chinese standards, the same below).

In July 2020, China released the Technical Guide for Formulating Emergency Emission Reduction Measures for Key Industries in Heavy Pollution Weather. Cement plants are classified into different environmental protection levels. Level A is the highest level, whose SO2 emission is limited to 35 mg/m3. Different cement enterprises respond to the peak shift production time according to their environmental protection level. Many provinces have formulated the cement plants’ operating days. For example, as required in Anhui Province’s Notice on Further Normalized Peak Shift Production of Cement, Class A plants can arrange their production days as they wish from December 1 to March 31 of the next year. Class B plants will be shut down for 30 d. Class C plants have to stop production for 60 d. Class D plants will be offline for 90 d.

Many provinces, such as Shandong, Shanxi, Henan, Hebei, Anhui, Jiangsu and Zhejiang have issued their own cement industry emission standards in recent years. In April 2022, the China Cement Association approved the release of the group standard of Ultra Low Emission Standard of Air Pollutants for the Cement Industry. These standards are more stringent than GB4915-2013. See

Table 1 for the summary of national standards and provincial standards.

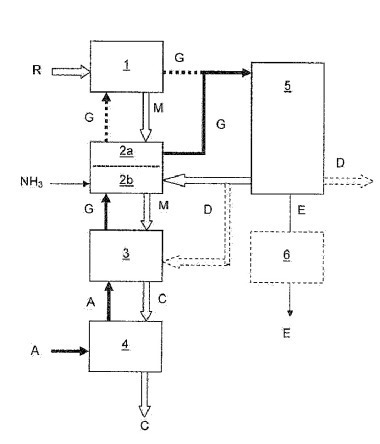

2 Input and output of sulfur in cement production

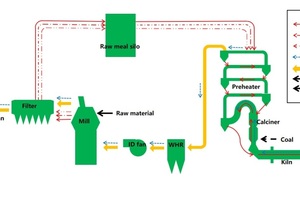

Most of the SO2 in the cement clinker production process comes from raw materials and fuels. Some scholars have carried out detailed and systematic analysis on this [4, 5, 6]. The input and output flow of sulfur is shown in Figure 1.

Pulverized coal enters the cement process system at the rotary kiln and calciner. During the combustion of coal, the sulfur in coal is converted into SO2 and released. Due to the high concentration of CaO in the calciner and the lowest cyclone, and the high concentration of flue gas in the calciner, SO2 reacts with CaO and O2 to generate CaSO4, which then enters the rotary kiln. Although a small amount of CaSO4 decomposes to release SO2 and SO3 again, CaSO4 is generated again in the calciner and the lowest cyclone. Finally CaSO4 is discharged from the system along with the clinker. This cycle is called the high-temperature cycle of sulfur among the rotary kiln, the calciner and the lowest level cyclone. Sulfur-containing substances in coal do not cause the emission of SO2 to exceed the standard.

Sulfur-containing substances in raw meal include sulfate, sulfur-containing organic matter and sulfide. Most of sulfide is pyrite (FeS2), and sulfate is gypsum (CaSO4) and anhydrite (CaSO4·2H2O). These sulfur-containing substances enter the cement process system from the raw mill, then the raw meal silo, and the preheater system through the raw meal elevator. Sulphate will enter the calciner with raw meal powder, go to the high-temperature cycle of sulfur, and be discharged out of the system with clinker, without affecting SO2 emission. Sulfur-containing organic matter, sulfide will decompose and release SO2 below 600 °C, which is the main reason for SO2 emissions in the chimney exceeding the standard. Therefore, if some cement plants’ SO2 emission exceeds the standard due to some raw materials’ high FeS2 or sulfur-containing organic content, the replacement of those raw materials may make SO2 emission meet the standard [7]. After SO2 is released from the cyclones at the upper part of the preheater system, it will react with limestone to generate CaSO3 and further oxidized to CaSO4, which is mixed into the raw meal powder. However, this reaction only occurs in the raw meal mill and is difficult to occur in other equipment. This is because the raw mill has a higher concentration of limestone powder, oxygen concentration and moisture content. Therefore, the SO2 emission concentration of most cement production lines is strongly related to whether the raw mill is running or not. The SO2 emission concentration when the raw mill is running is 50-80% of the concentration when the raw mill stops. This cycle is called the low temperature cycle of sulfur between the raw mill, the bag filter, the raw meal silo and the preheaters.

3 Flue gas desulfurization technology and its

application in the cement industry

At present, the desulfurization technologies adopted by Chinese cement enterprises can be divided into two categories from the source of technology: one is directly transplanted to the cement industry from other industries, and the other is developed in combination with the cement industry’s own characteristics.

The limestone-gypsum technology, the soda-lime double alkali technology, the ammonia desulfurization technology and the Ca(OH)2 desulfurization technology are usual desulfurization technologies in other industries. The raw-meal-powder technology, the CaO self-desulfurization technology and the compound desulfurization additives technology are developed by researchers according to the characteristics of the cement process.

3.1 The limestone-gypsum technology

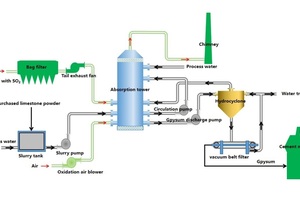

The limestone-gypsum technology is a commonly wet desulfurization technology in the coal power industry, and it is also the most popular desulfurization technology in all Chinese industries. The limestone-gypsum technology process flow directly to the cement plant is shown in Figure 2, which is generally divided into an absorbent preparation system, an absorption tower, a desulfurization gypsum treatment system, a water treatment system, etc. The chemical reactions of limestone-gypsum technology are as follows:

SO2 + H2O H2SO3

CaCO3 + H2SO3 CaSO3 + CO2 + H2O

2CaSO3 + O2 2CaSO4

The desulfurization efficiency of the limestone-gypsum technology can reach more than 95%, which can make SO2 < 35 mg/m3. However, if the cement plants directly copy the limestone-gypsum technology of power plants, they will have the following problems:

High cost of purchased limestone:

The particle size of limestone in a cement plant’s limestone silo is generally 1-60 mm, which can not meet the requirements of the limestone-gypsum technology. Therefore, the absorbent used is mostly purchased. The fineness is required to be 325 mesh (44 μm), and the CaCO3 content is more than 90%. The current market price of the limestone powder is about € 20 to 30 per t without considering the portation expense.

The waste water treatment:

The balance of stable PH value and ion concentration is the premise of normal operation of the limestone-gypsum technology. Because gypsum dewatering is required regularly, de-sulfurization wastewater will be generated.

The desulfurization wastewater has the characteristics of complex water components, great difficulty in treatment and high cost. Because SO2 is dissolved in desulfurization wastewater and SO2 is easy to ionize, the PH value of desulfurization wastewater is low to 4-6. Desulfurization wastewater contains CaSO4, CaSO3 and other solid suspended substances, which easily cause plugging and corrosion. The calcium hardness is high and easily causes scaling of the pipeline. In addition, heavy metals are easily enriched in desulfurization wastewater, which also increases the treatment cost. To treat the desulfurization wastewater, the factory needs to add NaOH and other alkaline substances, increase the PH value to above 9, form insoluble hydroxide precipitation for some heavy metal ions, then add organic sulfur to remove the heavy metal, and finally add PAM, PAC or other flocculants in the flocculation tank to make suspended particles coagulate and precipitate. The sediment as solid waste also needs further treatments.

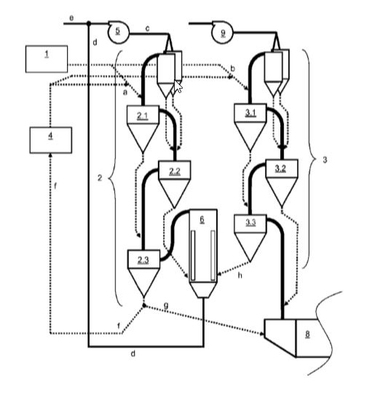

3.2 The raw-meal-powder technology

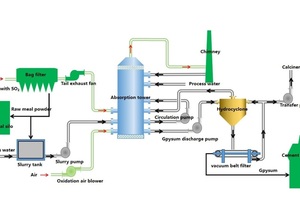

Due to the problems in the traditional limestone-gypsum technology above, the researchers have developed the raw-meal-powder technology in view of the characteristics of the cement industry. The process is illustrated in Figure 3.

The raw-meal-powder technology has following advantages:

Using the raw meal powder to replace purchased limestone powder:

The limestone powder absorbent is replaced by the raw meal powder. The fineness is about 240-325 mesh (45-60 μm), and the calcium carbonate content is about 40-44%. The cost of the raw meal powder is about € 3 to 4 per t including the portation expense.

Discharge the waste water to the calciner:

Cement kilns naturally have the advantage of disposing of wastes. Although the desulfurization waste water has the characteristics of low PH value, high calcium hardness, and suspended calcium sulfate, it is not a very difficult problem for cement kilns to coordinate the disposal of wastes. From the authors’ experience, it is only necessary to inject no more than 2 t of desulfurization wastewater into the calciner or the cooler every day. The cost of water treatment is nearly negligible.

Set backwater slope at the bottom of chimney:

At the bottom of the chimney, a backwater slope is set, and anti-corrosion materials and pipes are added to guide the water condensed in the chimney back to the desulfurization tower. In this way, the reuse rate of industrial water can be improved and the running cost can be reduced.

As this raw-meal-powder technology is more suitable for cement plants than the traditional limestone-gypsum technology, it has been rapidly promoted in China. The following is a brief introduction to a raw-meal-powder desulfurization system designed by the authors of a 5000 t/d cement clinker production line in Hubei Province. The design and running parameters are shown in Tables 2 and 3.

The raw-meal-powder technology’s running cost includes the consumption of the raw meal, the process water, the raw-meal-powder system power consumption and the cement system power consumption caused by the desulfurization tower. The consumption of the raw meal powder is a variable cost, and others are nearly fixed cost. For this project, the total power consumption cost is € 0.27 per t of clinker. The water consumption cost is € 0.01 per t of clinker, and the cost of absorbent (the raw meal powder) is € 0.03 per t of clinker. Total operating cost is € 0.31 per t clinker. The raw-meal-powder technology’s disadvantage is the high investment which is nearly € 2 million for a 5000 t/d cement clinker production line.

3.3 The soda-lime double alkali technology

The double alkali technology uses the NaOH solution to absorb SO2, then Na2SO3 and NaHSO3 solution generated reacts with CaO and oxygen in the regeneration tank to generate gypsum, so that NaOH solution can be regenerated and reused. The chemical equation of double alkali method is as follows:

SO2 + 2NaOH Na2SO3 + H2O

2Na2SO3 + SO2 + H2O 2NaHSO3

CaO + H2O Ca(OH)2

2Na2SO3 + O2 2Na2SO4

2NaHSO3 + O2 2NaHSO4

Na2SO4 + Ca(OH)2 2NaOH + CaSO4

NaHSO4 + Ca(OH)2 NaOH + CaSO4 + H2O

The double alkali technology has the advantage that Na2SO3 and NaHSO3 are soluble substances, and will not produce sediment to block the pipeline. Disadvantages of the double alkali method are below: The desulfurization gypsum contains Na2SO4, which increases the difficulty of utilization. The high pH value of the absorption solution is highly corrosive. The CaO’s price is high. The process flow is so long that the operation is complex, and the maintenance cost is high. In 2010, a 6000 t/d cement clinker production line adopted double alkali desulfurization in Guangdong Province. However, in 2020 due to the high running cost, the plant has turned to use the raw-meal-powder technology.

3.4 The ammonia desulfurization technology

The ammonia desulfurization technology refers to the method of spraying ammonia water or urea solution into the preheater or the humidifying tower to remove SO2. The reaction of ammonia desulfurization is as follows:

SO2 + NH3 + H2O NH4HSO3

SO2 + 2NH3 + H2O (NH4)2SO3

2NH4HSO3 + O2 2NH4HSO4

2 (NH4)2SO3 + O2 2 (NH4)2SO4

The ammonia desulfurization system is nearly equal to the SNCR (selective non-catalytic reaction) denitration system. The only difference is the ammonia water injection position. The ammonia desulfurization system adds the aqueous ammonia into the areas below 400 °C such as cyclone one or the humidifying tower.

The ammonia desulfurization technology’s advantage is its low investment. If a cement plant has a SNCR system, it only needs about € 10000 to add an ammonia desulfurization system.

The ammonia desulfurization technology’s desulfurization rate is about 80-90% [8]. If the target of less than 35 mg/m3 is to be reached stably, the initial SO2 emission concentration should not be higher than 300 mg/m3, which limits the ammonia desulfurization technology’s application scope. The ammonia desulfurization technology’s running cost is much higher than the raw-meal-powder technology. When the SO2 emission concentration is reduced from 1000 mg/m3 to 100 mg/m3, the aqueous ammonia consumption is 7.9 kg per t of clinker which means that the running cost is about € 1.5 per t clinker. In addition, this technology has a serious ammonia-escape problem which must exceed the 8-mg/m3-NH3-emission limit of GB4915-2013. Therefore the ammonia desulfurization technology might not suit the Chinese cement industry.

3.5 The Ca(OH)2 desulfurization technology

The Ca(OH)2 desulfurization technology has two processes. The chemical reaction is below:

SO3 + Ca(OH)2 H2O + CaSO4

SO2 + Ca(OH)2 H2O + CaSO3

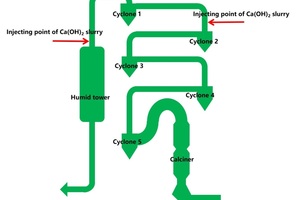

One process is the spray drying technology which means to make calcium hydroxide into slurry and inject it in the humidifier or cyclone one inlet. The spray drying technology is shown schematically in Figure 4. A cement plant in Shandong Province uses the water tank of the humidifying tower to set a compartment as the Ca(OH)2 slurry pool, and uses compressed air to stir the slurry pool [9]. The plant sprays Ca(OH)2 slurry into the humidification tower through six old humidification tower spray guns, which can reduce the SO2 emission concentration from 200 mg/m3 to 40 mg/m3. The spray drying technology’s advantage is its low investment and the disadvantage is its pipe is easily blocked. The spray drying technology suits plants whose SO2 emission concentration is very low.

The other process is to mix Ca(OH)2 into the raw meal powder before entering the bucket elevator. This method has low investment and can adjust the amount of Ca(OH)2 added according to different SO2 concentrations. It has been applied in many cement enterprises in China. The disadvantage of this method is the high running cost. In a 5000 t/d cement clinker production line in Henan Province [10], whose initial SO2 emission concentration is about 964 mg/m3, SO2 emission concentration is too hard to be controlled lower than 35 mg/m3. At that time the Ca(OH)2 consumption is up to 3.5 t/h, which means that the running cost is € 1.56 per t of clinker. Compared with the raw-meal-powder technology above (€ 0.31 per t clinker), this technology is too expensive.

3.6 The compound desulfurization additives

technology

The reason for the Ca(OH)2 desulfurization technology’s high operating cost is that the amount of calcium hydroxide sprayed is much higher than the amount required for theoretical reaction. From the chemical mechanism, the chemical reaction activity of SO2 is much lower than that of SO3 [11]. Therefore, the oxidation of SO2 to SO3 could reduce the amount of Ca(OH)2, and even promote the raw meal powder reaction with SO3 in the preheater. The process of the oxidation of SO2 to SO3 and the next desulfurization is called the compound desulfurization additives technology. SCR catalyst can catalyze SO2 to generate SO3, which is avoided as much as possible in SCR but beneficial to the desulfurization. The active component is the transition metal oxide such as titanium dioxide, vanadium pentoxide and manganese dioxide.

At present, dozens of enterprises in China sell the compound desulfurization additives. The sold compound desulfurization additives’ composition include the desulfurization additives, the SCR catalytic additives, or the oxidant additives. The desulfurization additives’ constituents are CaO, Ca(OH)2, and etc. [12]. The catalytic additives are TiO2, V2O5, MnO2, LiOH and etc [12,13]. The oxidant additives are KMnO4 [13].

Based on the practical effect [10], the compound desulfurization additives technology can make SO2 emission concentration from 964 mg/m3 to about 20 mg/m3 stably. The compound desulfurization additives are up to 1.5t/h, which means that the running cost is € 0.75 per t of clinker. Compared with the raw-meal-powder technology above (€ 0.31 per t clinker), the compound desulfurization additives technology is suitable for the cement plants whose initial SO2 emission concentration is below 500 mg/m3. At present, more than half of the Chinese cement plants who need desulfurization use this technology.

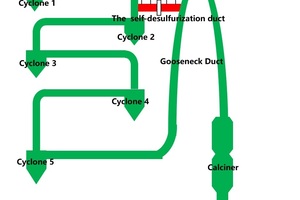

3.7 The CaO self-desulfurization technology

The CaO’s desulfurization effect is better than that of limestone. But in the preheater, CaO only exists in the calciner and the lowest stage cyclone, while sulfur-containing organic matter and sulfide in the raw materials releases sulfur dioxide in cyclone one, two and three. SO2 is discharged with the flue gas, and there is no overlap between CaO and SO2. The FLSmidth Company extracts some flue gas from the calciner outlet into a newly added cyclone, and then feeds the collected hot raw material into the flue gas duct between cyclone one and two. Several Chinese cement plants have adopted a similar technology for desulfurization, but none of them added a new cyclone. Instead, the flue gas from the calciner is directly introduced to the duct between cyclone one and two as Figure 5 or the outlet of cyclone one. In a cement plant in Xinjiang Uygur Autonomous Region, the CaO self-desulfurization technology’s desulfurization efficiency can reach 80%. The disadvantages are some inevitable impacts on production, such as the high dust temperature at cyclone one outlet, the increasing collapsing frequency in all cyclones, the block of the desulfurization flue gas duct, and the ID fan blades’ abrasion [15]. Because the CaO self-desulfurization technology can not absolutely meet the ultra low emission standard, a few cement plants use this technology.

4 Summary

Chinese central and local governments have set strict emission standards for the cement industry. Many cement plants have to cater to the SO2 limit of 35 mg/m3. SO2 emission of cement plant a is mostly caused by sulfur-containing organic matter and sulfide. Many technologies are applied in China. Among them, the compound desulfurization additives technology is the most widely used. The raw-meal-powder technology is placing the compound desulfurization additives technology in some plants whose intial SO2 emission concentration is over 500 mg/m3.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.