Smart refractory solution for stress loaded rotary kilns

The concept of a chrome ore free PERILEX® has been confirmed in numerous applications, so that a new, innovative and future-proof basic product for the lining of cement rotary kilns is available now.

1 Introduction

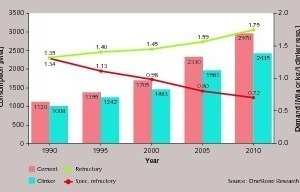

For example, the specific consumption of basic refractories dropped from 1.2 kg/t clinker in 1970 to its present value of 0.72 kg/t clinker (Fig. 1). Apart from the increased use of alternative fuels and raw...

1 Introduction

For example, the specific consumption of basic refractories dropped from 1.2 kg/t clinker in 1970 to its present value of 0.72 kg/t clinker (Fig. 1). Apart from the increased use of alternative fuels and raw materials, an important contribution to this very positive trend was made by the development of Refratechnik Cement’s AF technology.

2 Use of thermomechanically

insensitive magnesia chromite bricks

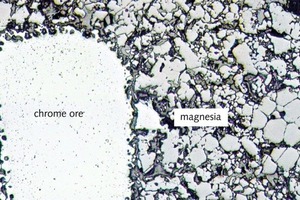

Contrary to this, the new PERILEX® 80 at that time was based on a European sintered magnesia, which exhibits a particularly elastic direct bridging bond between the chrome ore and the magnesia matrix thanks to an ingenious firing technique and the use of specially selected chrome ores (Fig. 2).

In addition, an effective crystal plasticity is ensured by the sintered magnesia used, so that any thermomechanical stresses due to the rotary kiln brickwork can not only be dissipated elastically without fracturing, but also plastically. The integration of coarse crystalline periclase in a periclase-magnesioferrite-spinel matrix together with a minimized amount of elastifying chrome ore, gives the brick a balanced ratio between thermal shock resistance, stress-reducing creep behaviour, and chemical resistance. These outstanding properties [2] ensured that under mechanical and/or thermomechanical load, PERILEX® 80 frequently gave better results than magnesia spinel brick types.

Due to its outstanding properties, more than 2 million tons of PERILEX® 80 have been produced since 1967 (> 200 million bricks). Expressed in the dimensions used by the cement industry, that is 208 km of lining in a kiln with 4.50 m diameter.

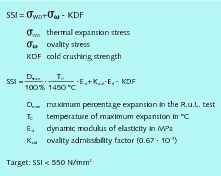

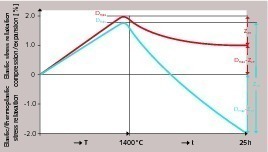

3 Basics of thermomechanical stress relaxation

Another factor of non-destructive, thermo-mechanical stress relaxation is creep, simulated in the laboratory by means of the creep in compression (CIC) method shown in Figure 5 [4]. This method serves to measure deformation under constant pressure and constant temperature during a defined period – mostly 25 hours. Normally, a balanced behaviour is aimed for, as inadequate CIC does not reduce the thermomechanical stresses, and can lead to spalling if the brick’s elasticity is too low. Too high a CIC value with simultaneously low refractoriness under load (R.u.L.) does not provide adequate resistance to higher thermal loads. In general, a high ta-value of ≥ 1550 °C from the R.u.L. test is required for the use of basic bricks in cement rotary kilns.

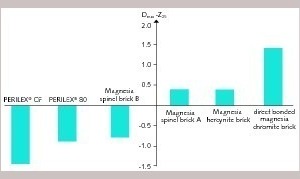

Figure 5 shows typical curves of bricks with low and with increased CIC. Characteristic values for thermomechanical stress relaxation are Dmax as maximum brick expansion – responsible for the amount of generated stress – and Dmax-Z (25 h) as a measure for thermomechanical stress relaxation.

4 Development and properties

of stress-minimizing, chrome ore free bricks

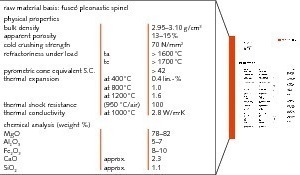

Based on new developments in raw materials [5] [6], the concept of using a pleonastic spinel as an elastifier could also be applied to a product based on an iron rich raw material. In its composition, pleonastic spinel, i.e. a spinel from the MgO-Al2O3-FeOx system, is closer related to a chrome ore than e.g. magnesium-aluminium spinel (Table 1). The chromium oxide of the ore is replaced by the oxides Al2O3 and MgO, and also by Fe2O3/FeO to a lesser extent.

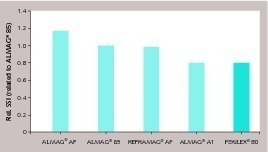

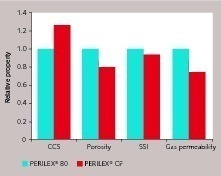

Applying the established AF technology and using sintered magnesia containing iron oxide (known from PERILEX® 80) with pleonastic fused spinel – a synthetic raw material – it was possible to manufacture the thermomechanically insensitive PERILEX® CF brick, which exhibits extraordinary physical properties and outstanding thermal shock resistance. Compared with the exceptional performance properties of a PERILEX® 80 brick, it was possible to increase mechanical strength by 20 % whilst maintaining the well-proven refractoriness (Fig. 6).

Due to the significantly lower porosity of about 13– 15 % compared with a value of 17–19 % for magnesia chromite bricks, and in combination with a reduced gas permeability from about 4 nPm to 3 nPm, it is even possible to achieve a 25 % increase of infiltration resistance without affecting the other properties.

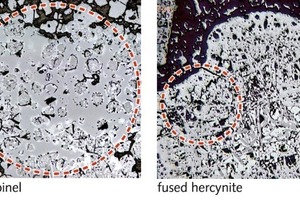

Stress sensitivity index and elasticity correspond to those of PERILEX® 80. The decisive value of CIC for thermomechanical stress relaxation is maintained, so a stress-reducing thermoplastic behaviour can be achieved for PERILEX® CF (Fig. 7). The thermochemical advantages of pleonastic spinel also result from the brick’s microstructural design (Fig. 8).

Due to diffusion of MgO and iron oxides, (MgO-free) hercynite is able to interact with its surrounding matrix [7], resulting in local porosities and microstructural inhomogeneities, which reduce the resistance of hercynite to cement clinker melt attack. Contrarily, such active reactions do not occur with MgO containing pleonastic spinel, so that a high level of corrosion resistance is given. Hereby, pleonastic spinel behaves similarly to magnesium-aluminium spinel, which also does not interact significantly with its surroundings.

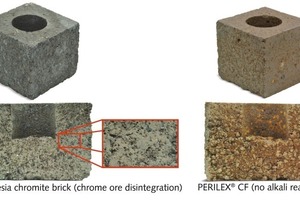

Although magnesia chromite bricks are undoubtedly still the standard product for cement kilns from a technical point of view, compared with spinel containing magnesia bricks, their importance has decreased significantly for ecological reasons. In an oxidizing atmosphere and in the presence of alkali oxides – i.e. the predominant conditions that occur in cement kilns – it is possible that the chrome ore is decomposed, whereby toxic alkali chromate may form [8]. Apart from the environmental impact, the elastifier is also corroded, so that the bricks may become brittle as well. This behaviour can be simulated very well in the so-called alkali cup test [9] at a temperature of 1350 °C with potassium carbonate as reagent (Fig. 9). Due to the disintegration of the chrome ore, the cup of a magnesia chromite brick shows clear pitting in the places where the chrome ore was located. The results are a loss of brick elasticity, and the formation of chromate. As can be expected, no such reaction is observed in a cup made of chrome ore free PERILEX® CF, as it does not contain minerals that can be corroded by alkalis.

Apart from the advantages of thermochemically stable pleonaste, which is more resistant to cement clinker attack than a hercynite [10], it is possible to use the advantage of a ferrous sintered magnesia, which exhibits a better coatability than a low iron natural or synthetic sintered magnesia (Fig. 10).

Due to the presence of pleonastic spinel, magnesio-ferrite, and also belite, the coating behaviour of magnesia pleonaste bricks based on a ferrous sintered magnesia is superior to those of magnesia hercynite bricks or even magnesia chromite bricks. The presence of highly viscous calcium ferrite and calcium aluminate compounds due to reactions between kiln feed and brick constituents, promotes the formation of a cement clinker coating on the refractory lining [6].

5 Lining recommendations

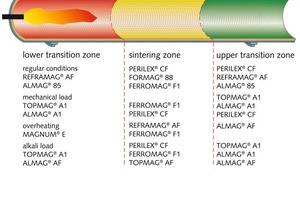

PERILEX® CF exhibits high resistance to alkali spalling, high infiltration resistance, low porosity, reduced gas permeability, excellent microstructural elasticity, and pronounced thermoplasticity. This results in a low sensitivity to mechanical stress, so that due to this combination of properties, PERILEX® CF is primarily suited for lining the central burning zone, and for the upper transition zones subjected to normal thermal and increased thermomechanical stresses (Fig. 12).

6 Summary

The concept of the chrome ore free PERILEX® has been confirmed in numerous applications, so that a new, innovative and future-proof basic product for the lining of cement rotary kilns is available now.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.