Basic kiln hoods – successful and innovative refractory concepts

The kiln hood of a rotary kiln in a cement plant connects the hot area of the kiln with the clinker cooler and is therefore always exposed to high thermal and process-related stresses. In recent decades, these loads have steadily increased in consequence of the use of alternative fuels and thereby induced higher process temperatures. For system builders, this means an enormous design effort, when rotary kilns are modernized.

1 Introduction

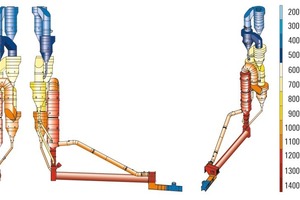

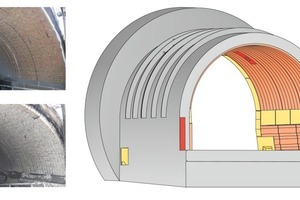

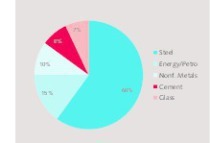

As a static unit, the kiln hood of a cement plant connects the hot area of the rotary kiln with the clinker cooler, and is therefore subjected to correspondingly high loads. In the past decades, these loads have increased continuously as a direct result of developments toward cement plants with modern process conditions, the use of alternative fuels as well as higher process temperatures (Fig. 1).

Especially the increasing modernization of older rotary kilns, that means the change from satellite coolers to more efficient grate coolers and correspondingly dimensioned kiln hoods,...

1 Introduction

As a static unit, the kiln hood of a cement plant connects the hot area of the rotary kiln with the clinker cooler, and is therefore subjected to correspondingly high loads. In the past decades, these loads have increased continuously as a direct result of developments toward cement plants with modern process conditions, the use of alternative fuels as well as higher process temperatures (Fig. 1).

Especially the increasing modernization of older rotary kilns, that means the change from satellite coolers to more efficient grate coolers and correspondingly dimensioned kiln hoods, resulted in higher loads to the kiln hood. This led to the need for complex refractory linings with individual problem solutions.

Moreover, the continuously increasing capacities of modern cement plants also gave rise to larger kiln hood volumes, which require specially engineered refractory concepts, too. Refratechnik Cement GmbH, Göttingen, recognized these problems in the early 1990’s and has meanwhile developed basic lining concepts for kiln hoods, which meet all the demands of modern cement plants. An overview of these concepts using the examples of different kiln hoods is given in the following.

2 Loads in the kiln hoods

In the kiln hood, the hot clinker is discharged into the cooler. This means that the hood is subjected to some of the highest thermal stresses in a cement plant, and therefore requires a multi-layer refractory design. In the kiln hood dropping down of the hot clinker into the cooler takes place. In modern plants with precalcination, the hood has a connection to the tertiary air duct, which leads to the preheater. Consequently, the refractory lining in this area is subjected to four basic stress factors:

high radiant heat of the hot clinker with temperature peaks up to 1600 °C,

alkali load due to alternative fuels introduced through the main burner,

evaporation of the alkalis contained in the clinker,

hot and highly abrasive secondary airflows from the clinker cooler, that means laden with clinker dust and with temperatures up to 1150 °C.

These factors must always be regarded as “combined stress loads” in the kiln hood, which can have different effects, depending on hood volume and type.

As already mentioned, thermochemical loads in the kiln hoods have increased in the past years due to higher kiln outputs and more efficient coolers with high secondary air temperatures. In the past, alumina products were used for conventional refractory linings of kiln hoods – in different combinations with refractory bricks or concretes, depending on customer requirements. Simply the high thermal loads, in particular the occasional peak temperatures, make alumina products reach their limits. Here, other thermally more resistant products, such as magnesia spinel bricks, are required. In addition to the physical infiltration of salts and their crystallization in the pore spaces, alumina grades are subjected to other thermochemical reactions.

Hereby, circulating alkalis, which are introduced by alternative fuels, lead to so-called alkali spalling (Fig. 2). During this process, the alumina components are attacked by alkalis, leading to new mineral formations such as feldspar and feldspathoids. These result in strong mineral growth that damages the brick lining, which in turn causes surface spallings. Infiltrated salts minimize brick porosity, reduce brick elasticity, and their crystallization pressure causes additional damage to the brick’s microstructure.

Subsequently, salt-laden alumina bricks exhibit an uncontrolled expansion, i.e. spallings, and thereby contribute to the instability of the brickwork or the monolithic lining. Apart from alkali attack and salt infiltration, growth effects induced by raw materials also play a considerable role with products based on andalusite. So, there commences mullitization at temperatures above 1350 °C, which is accompanied by a volume expansion of up to 7 %. This also contributes to extensive brick spallings. The result is a considerably shorter lifetime and the consequential need for regular and time-consuming repairs that depend on the dimensions of the kiln hood. In particular, very large kiln hood vaults require the time and cost-intensive installation of complex sub-structures and scaffolding work, which lead to longer kiln downtimes.

3 Innovative refractory linings

for optimized lifetimes

The thermochemical reactions described previously do not occur in basic bricks, which make this type of refractory lining appear to be far more advantageous. As with a rotary kiln lining, the known expansion of basic bricks is compensated for by providing suitable allowance for expansion joints in the initial lining, which practically equals a “controlled” expansion. Basic linings react far more flexibly to the seasonal start-up and shutdown of the rotary kiln, and lead to far less brick losses in the static units. Together with a corresponding “care” of the expansion joints during every kiln downtime – that means cleaning the joints and re-filling them with new, flexible refractory mats – this results in longer lifetimes of the kiln hood lining. This approach should also be followed in all other static units, such as cooler and cyclones.

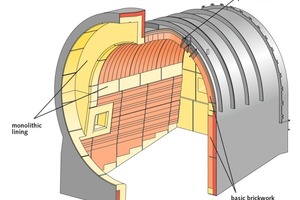

Depending on the steel structure configurations of the kiln hood units, various engineering concepts have been implemented during the past 15 years. Hereby, kiln hood vaults account for a major part of the constructions. The magnesia spinel brick types REFRAMAG® 85, ALMAG® A1, and ALMAG® 85 are used for this purpose. Figure 3 shows a diagrammatic overview of the lining options for the kiln hood of an ongoing project, which will be presented in more detail in the following.

A frequently heard argument against basic linings is the expansion behaviour of magnesia spinel bricks mentioned previously, as well as their higher thermal conductivity compared with alumina products. However, many different lining types have shown that by means of a suitable wall design, it is possible to control the temperature gradient in such a way that no excessive loads occur in the system.

The following examples show a few successful lining concepts that are characterized by excellent lifetimes.

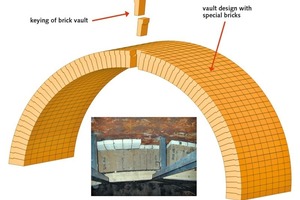

3.1 Vault construction

Figure 4 shows the refractory construction of the kiln hood vault in a leading German cement plant. The relatively large vault diameter of about 9 m was lined in two layers with a total thickness of 350 mm. The insulating layer consists of 50 mm thick lightweight refractory bricks. The working lining was installed using 300 mm thick ALMAG® A1 bricks with the tongue and groove technology developed and patented by Refratechnik Cement GmbH. Hereby, the bricks rest over their entire width on the tongue of the adjoining brick. This gives an optimum force distribution, so that load peaks are avoided [1]. In this way, the vault is given additional thermomechanical stability, which is particularly required and advantageous in large barrel vault constructions.

In Figure 5 the condition of the refractory lining after lifetimes of 2 (left) and 9 years (right) is shown. After a total service life of 9 years, this lining concept was applied again in the kiln hood.

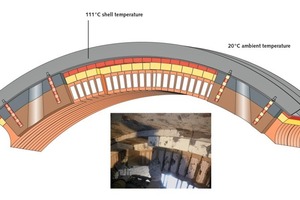

In another well-known German cement plant, the kiln hoods of both kiln lines were lined with a basic refractory material. The three-layer design has a working lining of ALMAG® 85 with a thickness of 220 mm in the standard VDZ shapes B322 and B622 (Fig. 6). The two insulating layers consist of lightweight refractory bricks with a height of 76 mm (shape 1-76), and a 50 mm thick calcium silicate plate with barrier coating. This configuration gives a theoretical shell temperature of 111 °C at an ambient temperature of 20 °C, calculated without wind effects. With a diameter of less than 5 m, the size of the kiln hood permits the lining to be applied with the help of normal rotary kiln lining equipment like the REFRA-Rig II.

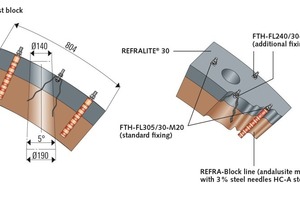

Figure 7 shows the partial view of the finished kiln hood lining as well as a photograph of the same view after a lifetime of about 8 months. A special feature of this kiln hood lining was the area around the cable grommet to the kiln ramp. As stated by the customer, in the past some severe refractory damage occurred in this area already after lifetimes of less than a year, so that repair work was often required several times a year. An outstanding solution was found with a special design using a precast block, which was then also installed in the identically lined kiln hood of the second kiln line (Fig. 8).

This precast block was manufactured in Refratechnik Steel GmbH’s production site for preformed shapes in the city of Dülmen. It consists of an insulating layer of REFRALITE® 30 insulating concrete, and a working lining made of dense refractory concrete on andalusite raw material base (REFRA-Block line®). The location of the inner sleeve for the cable grommet, as well as the entire shape of the precast block had to be matched precisely to the kiln hood dimensions, in order to achieve the desired effect. After eight months of lifetime, the precast block as well as the surrounding lining of ALMAG® 85 bricks exhibited no signs of damage (Fig. 9).

Already in the past, both kiln hoods of this cement plant were lined with basic ALMAG® 85 bricks, whereby lifetimes of 8 to 9 years were achieved. This optimum result convinced the customer to apply this successful refractory concept again.

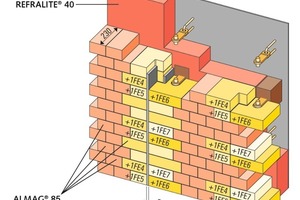

3.2 Wall construction

The walls below the vault of the kiln hood as described earlier were lined using a two-layer concept, as shown in Fig. 10. The ALMAG® 85 anchor bricks in shapes +1FE4 up to +1FE7 have a thickness of 230 mm, and the matching anchor brackets of 1.4835 grade steel are wrapped in refractory wool for additional protection. A 151 mm thick layer of REFRALITE® 40 insulating concrete is placed behind the anchor bricks. Moreover, 20 mm expansion joints are provided to compensate for the expansion of the magnesia spinel bricks.

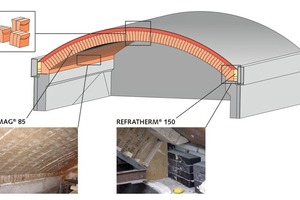

3.3 Special solutions together with customer and kiln constructor: cement plant in Spain

Due to permanently recurring refractory problems and unsatisfactory service life, caused for example by large amounts of dust and high temperatures, the plant management decided to rebuild the kiln hood from an originally flat design that was completely lined with refractory concrete, to a vaulted design. Moreover, due to the increased kiln hood volume, the secondary airflow speed was to be reduced, thereby also reducing the abrasive effects on the refractory lining. Rebuilding of the steel structure was carried out by a local company. Refratechnik was contracted for the special design of the refractory lining. The working lining of ALMAG® 85 bricks with a thickness of 300 mm was installed applying the tongue and groove technology. The lateral supports were installed using special shapes, also made of ALMAG® 85, together with REFRA-THERM® 150 insulating bricks fixed with gusset plates. To insulate the vault, a high-temperature fiberglass plate of 100 mm thickness with barrier coating was chosen (Fig. 11).

The lining with this new vault solution was completed in February 2007, and an inspection after a five years performance gave highly satisfactory results. Systematic temperature measurements of the metal shell before and after rebuilding show on average, that this new refractory vault design reduced the temperatures by half. The aim of a considerably longer lifetime of the refractory material, and the associated significant reduction of maintenance costs during this time, was achieved completely.

4 Summary and outlook

A short outline about conventional and newly developed refractory lining concepts for kiln hoods was given. Meanwhile, it has been shown that basic refractory linings used in this kiln – based on the experience gained on a large number of projects – have resulted in highly satisfactory lifetimes. Hereby, the vault design using high-grade magnesia spinel bricks, such as ALMAG® 85 and ALMAG® A1 for the working lining, has proved to be an ideal “workhorse”. Depending on the kiln hood’s geometry and the load the plant is subjected to, refractory light weight bricks are most suitable for insulation in modern cement plants.

However, one elementary question remains at the end: How will future requirements develop for cement plants in general, and for kiln hoods in particular? Of course, any prediction of the future will be speculative, but can still be made in connection with a review of developments in the past decades.

Alone the continuously increasing use of alternative fuels in the cement industry will greatly increase the thermochemical requirements for kiln hood linings. In line with the trend to higher capacities of cement plants, future kiln hoods will have even larger dimensions, which will make optimized lining concepts necessary. This indicates a great potential for professional engineering services.

Of course, increasing cost pressures and economic considerations are dominant whenever the refractory lining of a cement plant is involved. Even though the basic lining of a kiln hood appears to be more expensive than a conventional solution with alumina products at first sight, the advantages during normal operation with longer service life soon become apparent. Moreover, reductions in maintenance costs are achieved during the longer life cycles.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.