Simplifying the geometry of a parallel-flow regenerative (PFR) kiln to

achieve both long-term cost savings

and process advantages

The following presentation focuses on PFR kilns, explaining their process engineering and discussing the authors’ proposal for simplifying the geometry of PFR kilns in order to achieve cost savings in combination with process advantages.

1 Introduction

Different lime kiln types, e.g., rotary kilns and shaft kilns, are used for lime production. The last-mentioned type is found mainly in Germany. Soft-burnt lime is generally produced in the following types of kiln: parallel-flow regenerative (PFR) kilns, annular shaft kilns and normal shaft kilns equipped with side burners positioned in the lower third of the kiln. Most medium- or hard-burnt lime is produced in mix-fired normal shaft kilns (NSK), where the kiln is simultaneously charged with solid fuel and limestone. Such kilns are also used in the soda and sugar industries....

1 Introduction

Different lime kiln types, e.g., rotary kilns and shaft kilns, are used for lime production. The last-mentioned type is found mainly in Germany. Soft-burnt lime is generally produced in the following types of kiln: parallel-flow regenerative (PFR) kilns, annular shaft kilns and normal shaft kilns equipped with side burners positioned in the lower third of the kiln. Most medium- or hard-burnt lime is produced in mix-fired normal shaft kilns (NSK), where the kiln is simultaneously charged with solid fuel and limestone. Such kilns are also used in the soda and sugar industries. While various other types of kiln are also in use, their production output rates are low in comparison with that of the aforementioned models. All types of lime kiln mentioned to this point, with the exception of mix-fired normal shaft kilns and a few others, were first developed in the 1950s and have since been partially improved, but with no significant innovations added.

Table 1 ranks the lime kilns presently in use in Germany in descending order of frequency. Clearly, the most widely employed types are the NSK, PFR and annular shaft kilns – compared to a mere five rotary kilns. It is evident that PFR-type and annular shaft kilns are used mostly for soft-burning lime, because hard lime is more expensive to produce.

2 PFR kilns

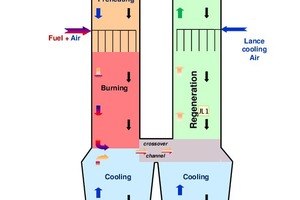

Today’s standard PFR kilns consist of two identical, vertical shafts connected to each other by a cross-over channel, as shown in Figure 1. The two shafts serve alternatively as burning shaft and regenerative shaft for the duration of the so-called cycle time, during which each shaft performs its own function that can be freely chosen as a process-related parameter. The switchover from burning to regeneration is referred to as the reversal time.

In principle, PFR kilns operate under pressure. In the burning shaft, compressed combustion air is blown into the kiln at the head end. This air absorbs the heat from the limestone in the so-called preheating zone, which was newly charged and preheated by the waste gas during the previous cycle time (function: regenerative shaft). The fuel is injected through a certain number of lances distributed vertically over the cross section of the kiln in the direction of gas and limestone flow. The preheating zone ends at the tip of the lances.

The following types of fuel are generally used:

gas (natural gas, coke oven gas, etc.)

powdered solid fuel (lignite, hard coal)

liquid fuel (heavy oil, light oil)

The powdered solid fuel is blown in with air. The transporting air has two functions, i.e., to transport the fuel and to cool the lances. The employed amount of transporting air is subtracted from the total combustion air requirement in order to maintain the chosen air-fuel ratio for the type of fuel in use (air coefficient).

The burning zone begins at the end of the preheating zone. Here, the process heat generated by fuel combustion subjects the product to thermal treatment. During the calcination process, the limestone is converted to lime, during which carbon dioxide gases are released to become part of the waste/process gas. The flame is in direct contact with the limestone. The burning zone ends where the generated process heat has become too low to sustain the calcination process.

The process gas and the limestone/lime column flow in co-current mode through the preheating and burning zones of the burning shaft. In the cooling zone, pressurized cooling air is supplied to the limestone/lime column in a counter-current arrangement. The process gas and cooling air flow together through the ring channel and crossover channel (connecting the two shafts; see Figure 1). In both shafts, the ring and crossover channels are positioned between the burning and cooling zones. Only PFR kilns with round shafts have a ring channel. If the shafts are rectangular, the process gas and cooling air flow directly from one shaft to the other via the crossover channel.

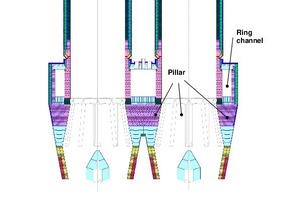

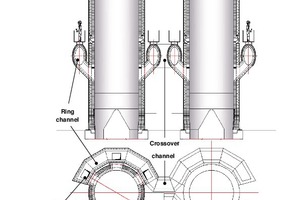

In a conventional PFR kiln with round shafts, the ring channel is formed by an inner cylinder and an outer shaft with floor and ceiling of brickwork or monolithic material. The ring channel is an integral part of a PFR kiln. The brickwork of the inner cylinder is either supported by an arch-and-pillar structure (cf. pillar kiln, Figure 2) or formed by a pendulous, double-walled steel cylinder (cf. kiln with pendulous cylinder, Figure 3).

The gas arriving via the crossover channel mixes with the cooling air in the regenerative shaft and, further up, with the cooling air from the lances. The combined gas flow passes through the column of limestone (charged during the previous reversal time) in countercurrent mode and, in doing so, gives off its heat to the stone.

Thanks to regenerative heat recovery, PFR kilns have very low specific energy consumption in comparison with other types of lime kilns, and they are accordingly widespread.

Pillar-supported PFR kilns, as Figure 2 shows, have the disadvantage that the brickwork of the pillar is exposed to high temperatures on three sides. The thermal stresses resulting from kiln operation, together with the heavy load of the inner cylinder, can eventually lead to pillar failure due to cracks forming in its brickwork. The so-called working lining, i.e., the brickwork of the inner cylinder, is exposed to high pressure loads by the weight of the limestone/lime column. Often, this causes the brickwork to move radially outward, resulting in a direct influx of process air into the ring channel. In either case, properly-controlled kiln operation is no longer possible, and the kiln has to be shut down. The specific amount of refractory material required for a given kiln capacity is very high, as is the cost of corrective maintenance in case of brickwork failure.

One drawback of PFR kilns with pendulous inner cylinder is that, as shown in Figure 3, it takes an extremely high technical effort to properly support the brickwork. A double-walled, air- or liquid-cooled steel cylinder in which an uninterrupted flow of coolant dissipates the heat into the brickwork is required.

Unfortunately, this has the disadvantage of removing heat from the actual process. In addition, blowers or pumps are required for supplying the coolant, with the consequence of increasing the kiln’s total energy consumption.

Add to that the fact that the bottom end of the brickwork, i.e., the end of the cylinder barrel, still constitutes a problem that has not yet been satisfactorily solved. This leads to reduced operational readiness and lower productivity due to frequent failure and corresponding unplanned shutdowns of the kiln.

Both types of PFR kilns (pillar supported kilns and kilns with pendulous cylinder) have round shafts and rectangular transverse sections in their ring channel, as shown in Figures 2 and 3. All these kilns face a serious problem caused by dust first being entrained in the flow of gas, then dropping out and accumulating, most notably in dead zones. Such deposits require laborious removal by hand at regular intervals with the aid of compressed air or water. The alkaline dust tends to sinter onto the refractory material, which therefore requires frequent cleaning. Especially the water used for cleaning attacks the refractory material, thus accelerating its rate of wear and again increasing the cost of maintenance.

So-called magnesia bricks consisting of highly purified, appropriately sintered magnesium oxide are the preferred refractory material for such kilns. The drawback here, however, is that magnesia bricks become hydrated in the presence of water, leading to their ultimate destruction.

3 Modification of a PFR kiln

Considering the above, the authors set themselves the task of building a kiln aggregate for burning lumpy mineral material – based on a less complicated design that would be more maintenance friendly and economical both in construction and in operation, as compared to a round, conventional-type PFR kiln. The basic mode of operation and the applied processing technique remained unchanged.

The most significant feature of the modification, as to be seen in Figure 4, is that the ring and crossover channels are situated outside of the kiln, so that now, neither channel is an integral, internal part of the kiln. That fact yields a number of advantages:

1. The modified PFR kiln consists of two identical round shafts (burning shaft and regenerative shaft), each with the same inner diameter and, hence, the same cross-sectional area. This reduces the specific weight of the lining in relation to the kiln’s capacity and greatly improves its structural strength. The cylindrical shape of the shaft wall imposes a significantly lower level of mechanical stress on the limestone/lime product and the brickwork, hence lengthening the service life of the refractory materials.

Since less refractory material and structural steel are required, the cost of construction is lower – as reflected by the amount of lining material required for, e.g., a 450 tlime/d PFR kiln. The envisioned modification reduces the refractory material requirement by roughly 30 %.

2. The need for custom shapes and sizes in the refractory lining is also significantly lower, further decreasing the cost per ton of refractory material. The use of standard-size bricks significantly accelerates the return of availability in case of repair. Such a kiln is very easy to build in a shorter time, because no complicated installations are needed. No pillars or similar supporting members have to be taken into consideration. All in all, this cuts the cost of installation by approx. 30 %.

Installing a console above the waste-gas channels considerably reduces the necessary frequency of overhaul inspections in the principal area of wear, so the associated costs are significantly lower, as well. The console approach can be instituted in the course of kiln conversion, too, since the static loads to be contended with by the modified kiln are much lower than for the original, conventional PFR kiln.

3. The cross sections of the transfer points between the kiln and the external ring channel can be adapted and optimized for the kiln’s own particular conditions of flow. This, in turn, optimizes the gas supply line to the regenerative shaft, hence yielding homogeneous distribution of heat over the cross section of the regenerative shaft. The existing openings in the brickwork of the cylindrical shaft have no influence on the static strength of the shaft’s masonry.

4. The external ring channel can be prefabricated in segments, and individual segments can be replaced as necessary in the course of operation, i.e., with no need for shutting down the kiln or otherwise interrupting its operation. The inner lining of the ring channel can be made of material that is better able to withstand the strains of cleaning, especially when water is used. Mineral brickwork and highly heat-resistant alloys make suitable choices.

The cross sectional geometry of the ring channel can be accommodated to the conditions of gas flow such that optimal mixing of the process gas and cooling air is ensured. This measure reduces the kiln’s tendency toward dust accumulation by ruling out dead spaces thanks to good consistency of flow resulting from the uniform geometry. This, too, significantly reduces the necessary frequency of cleaning.

Within the ring channel, technical measures can be integrated to reduce pollutant emissions from the kiln, e.g., by the targeted addition of appropriate media or ingredients.

5. With this kind of kiln modification, the following options are also available:

Two conventional-type shaft kilns standing side by side can be converted into a single PFR kiln, and

an existing, conventionally built, round PFR kiln can be modified as described, possibly enhancing its performance at the same time. The cost of modification for an existing kiln is quite reasonable, since the expense incurred for the requisite steelwork is nearly canceled out by the savings on refractory material in connection with a major maintenance inspection.

4 Summary

The authors have applied themselves to the task of modifying a conventional, round PFR kiln to the extent of simplifying its design while altering neither its mode of operation nor the applied lime-processing technique. The most significant feature of this modification is that the ring channel and crossover channel are situated outside of the kiln. Unlike the case of a conventional, round kiln, the two channels no longer constitute integral, interior parts of the kiln.

These modifications bring with them a number of advantages, mainly:

savings on lining material requirements

longer service life

reduced preventive maintenance

reduced corrective maintenance

process benefits

All these advantages are accompanied by significant cost savings.

The main advantage of this new kiln design is that it enables modification of two juxtapositioned, conventional-type shaft kilns to obtain a single PRF kiln. Likewise, an existing conventional-type round PFR kiln can be converted to the new design, as well. In either case, the problematic nature of a pillar-supported kiln or of a pendulous-cylinder kiln is eliminated. The cost of such a modification for a conventional PFR kiln remains within justifiable bounds.

The modified PFR kiln design, as described above, has already been discussed with a number of kiln-operating companies and was very well received, including shows of interest in actually modifying conventional PFR kilns to reflect the new design.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.