Research on the influence of the carbon nanotubes injection method on cement composite properties

In the paper, various methods of CNT (carbon nanotubes) injection into cement composites are studied. Modified slurry mix is studied on setting time, heat emission development and chemical shrinkage. Physical and mechanical properties of the slurries modified with CNT and superplasticizer are observed.

1 Introduction

One of the ways of service properties development for heavy weight concrete is modification with chemical additives and carbon nanotubes (CNT). In the present state of the art, the study of properties of CNT modified concrete is our main interest [1]. There are several types of nano-additives. And the use of upstretched nanoparticles – for instance CNT – has been proven to be more efficient for mechanical properties development [2]. They have high strength, acid and alkali chemical inertness. CNT reinforces cement brick and serves as crystallization centers, making of it a...

1 Introduction

One of the ways of service properties development for heavy weight concrete is modification with chemical additives and carbon nanotubes (CNT). In the present state of the art, the study of properties of CNT modified concrete is our main interest [1]. There are several types of nano-additives. And the use of upstretched nanoparticles – for instance CNT – has been proven to be more efficient for mechanical properties development [2]. They have high strength, acid and alkali chemical inertness. CNT reinforces cement brick and serves as crystallization centers, making of it a high-strength material [3].

Two modifying methods for cement based concretes with the use of nanoscaled particles are available [4]:

nanoscaled particles preparation and insertion into the concrete mixture

deliberate growing of required nanoscaled particles in a modified curing system

For the present the first method is more wide-spread, but due to their high surface activity, the CNT unite into a conglomerate in the form of powdered grains i.e. have a tendency to agglomeration which complicates homogeneous distribution over composite volume.

In this paper we present studies on the influence of the CNT insertion method (in combination with superplasticizer) on physical and mechanical properties of cement composites. We have used CNT “Taunit” by LLC “Nanotechcentr” as a modifying additive for cement composites. This additive represents a nanofiber and nanotubes mixture with a particle size of 40-60 nm in diameter and a length of up to 2 µ.

Today, several methods of efficient dispergation of CNT agglomerates are suggested – the hydrodynamic cavitation method [5], the method of ultrasonic exposure (USE) [4, 6]. In the present article the comparative results of two CNT insertion methods into cement composite are shown (by means of mechanical mixing and by means of USE in surfactant medium).

2 Experiments

We have used a superplasticizer “Giperlit” as a surfactant. It represents a copolymer based on polyoxyethylene derivatives of unsaturated carboxylic acids containing 30-35 % of dry substance. This additive is produced by LLC “Svan”. Recommended dosage is 0.2-1.5 %.

We have studied two compounds of complex additive (CA), containing 0,005 % of CNT and 1.25 % of superplasticizer “Giperlit”. Percentage is shown by weight of cement. We have mixed CNT in the superplasticizer solution by means of a propeller stirrer during 2 min at a rotating speed of 300 rpm to make the first compound. The second compound has been obtained by means of USE at an exposure duration time of 3.5 min and a US power output of 100 W.

Table 1 shows:

the influence of compound additives with different CNT insertion methods

comparative influence of CNT and superplasticizer (added in gauged water by the conventional method) on setting time and normal consistency measured according to GOST 310.3-76 “Cements. Methods for determination of standard consistency, times of setting and soundness”.

In the study, we have used Portland cement SRPC400 D20 GOST 22266-94 produced by the Volskcement plant (Holcim group).

Table 1 expresses that the “Giperlit” additive has a reduced water consistency of cement slurry and an increased initial set time by 160 min and a final set time by 200 min. Under condition of CNT insertion without superplasticizer, initial set time has been decreased by 25 min and final set time by 35 min in comparison with the compound without additives.

On the condition obtained by mechanical mixing of CNT in a superplasticizer medium, the water demand has remained constant and the initial setting time has increased from 170 up to 290 min, which is still 40 min less compared with a mixture containing superplasticizer only. The final setting time has increased from 220 up to 350 min and it is 70 min less in comparison with mixture2 in Table 1.

Under condition of insertion of CA (obtained by means of USE on CNT in superplasticizer medium), the water demand has remained the same compared with a compound containing superplasticizer only (compound 2).

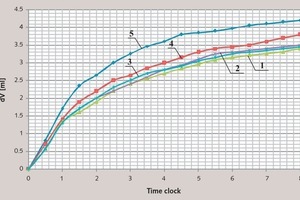

In comparison with the compound without CA, the setting time for slurry mix of normal consistency has increased, but compared with the compound containing CA (obtained by means of mechanical mixing of CNT and superplasticizer) the setting time has decreased. For instance the initial setting time has decreased by 75 min, and the final setting time by 60 min, relatively. We have used methods of chemical shrinkage and heat emission measurement to analyze the influence of CA under study of the slurry mix hydration processes. Chemical shrinkage of the slurry mix has been observed by means of a “Cement-prognoz” device. The results are shown in Figure 1.

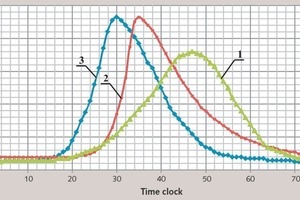

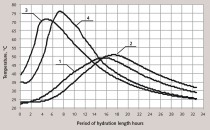

As is evident from Figure 1, all complex additives have increased the chemical shrinkage and it shows us the Portland cement hydration processes acceleration. It is worthy of note that the largest chemical shrinkage rate has been observed in CA containing compounds, particularly in compound 5 (where CNT have been exposed to USE in a superplasticizer solution). Heat emission development has been observed by means of a “Termochron” measurement set. The results are shown in Figure 2.

This figure also shows that the CA insertion leads to a 10⁰C increase in hydration temperature compared with the check compound (mixture 1), regardless of the preparation method. At the same time the preparation method affects the shift of the temperature maximum to the axis of the ordinates, which also shows us cement hydration processes acceleration. The largest acceleration has been observed in the compound with CA containing CNT after USE in a superplasticizer medium (mixture 5).

CNT insertion method impact on the physical and mechanical properties of cement slurry has been studied. Experimental works have been conducted according to GOST 310.4-81 “Cements. Methods of bending and compression strength determination.”

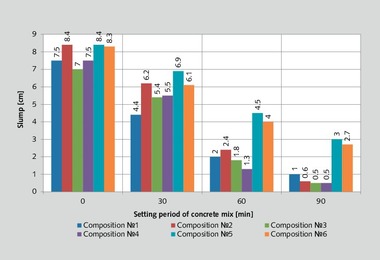

In our research we have used sand with a fineness modulus 2.7 from the Kamskoe Ust’e field as a fine aggregate. Experimental results are expressed in Figure 2 which shows that, under condition of optimal content of “Giperlit”, additive insertion into cement slurry leads to an increase in bending resistance of cement-sand composition. The composition bending resistance rise at 7 days is equal to 30 %, at 28 days equal to 26 %, and compressive strength rise is equal to 38 % and 22 %, respectively, in comparison with the mixture without additive.

Under condition of CNT insertion into superplasticizer and mechanical post-mixing in gauged water (mixture 4), the composite bending resistance at 7 days of standard curing increases by 35 %, after 28 days by 30 %, and the compressive strength rise is equal to 42 % and 29 % at 7 and 28 days, respectively. CA modified sand-cement composition (where CNT have been exposed to USE in superplasticizer solution) has shown that the bending resistance rise at 7 and 28 days is equal to 41 % and 36 %, respectively, and the compressive strength increases by 55 % and 46 % compared with the check compound.

3 Results

The analysis of the obtained data allows us to make the following conclusions:

CNT insertion into cement slurry in a dosage of 0.005 % by cement weight leads to a 25-35 min decrease of setting time.

CNT insertion into gauged water together with superplasticizer under a condition of mechanical pre-mixing has reduced the setting time by 40-70 min compared to a mixture containing superplasticizer only.

Bending resistance of sand-cement compositions obtained by insertion of CNT and superplasticizer under condition of mechanical mixing in gauged water has increased by 29 % and the compressive strength rise in this case is equal to 42 % compared with the check compound.

Under the condition of CA (mixture 5) insertion into cement slurry (where CNT has been exposed to USE in the superplasticizer solution) the setting time was reduced by 60-75 min compared to a mixture obtained by mechanical mixing of the studied additives in gauged water. Also we have achieved the largest increase in compressive strength and bending resistance which is equal to 36-55 % compared to a check compound without additives.

A combination of CNT and superplasticizer leads to a Portland cement hydration processes acceleration regardless of the insertion method and it is more significant in the case where CA containing CNT dispersed in a superplasticizer solution has been used.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.