Repair materials for sulphatically and hydraulically bonded masonry

Two research projects aimed to provide alternative materials for the rehabilitation of masonry damaged by destroying minerals were conducted at Bauhaus-Universität Weimar. The goal of the first was to reduce formation of ettringite and thaumasite in damaged sulphatic masonry by introduction of silicic acid esters (SAEs), while the second dealt with validation of a repair material for sulphatically and hydraulically bonded masonry. This contribution presents the initial findings.

1 Introduction

In several parts of Germany, at least until the late 19th century, many buildings made of artificial stone (e.g., bricks) and natural stone (e.g., slate, limestone, sandstone, gypsum rock) were bonded with gypsum (or gypsum-based) mortar. Particularly in Thuringia, Saxony-Anhalt, Lower Saxony, Hamburg, Bavaria and Baden-Württemberg, such mortar was in commonplace use due to the local natural occurrence of gypsum and advantageous means of transport (e.g., by water to Hamburg). Albeit, pertinent examples can also be cited for Berlin, Hesse, Mecklenburg-Vorpommern and...

1 Introduction

In several parts of Germany, at least until the late 19th century, many buildings made of artificial stone (e.g., bricks) and natural stone (e.g., slate, limestone, sandstone, gypsum rock) were bonded with gypsum (or gypsum-based) mortar. Particularly in Thuringia, Saxony-Anhalt, Lower Saxony, Hamburg, Bavaria and Baden-Württemberg, such mortar was in commonplace use due to the local natural occurrence of gypsum and advantageous means of transport (e.g., by water to Hamburg). Albeit, pertinent examples can also be cited for Berlin, Hesse, Mecklenburg-Vorpommern and Schleswig-Holstein. Prominent examples of gypsiferous masonry include the main structure of the Anna Amalia Library in Weimar, the Lübeck Cathedral, the Church of Saint Catherine in Hamburg, St. Mary’s Church in Lübeck and Runneburg Castle in Weissensee [1].

Frequently, in connection with restoration work, the fact that sulphatic masonry can contain large amounts of gypsum is either unknown, ignored or grossly underestimated. Consequently, the employed material is often unsuitable. Within a few years, sometimes only a decade or two, buildings thus rehabilitated display damage caused by expansion and deconsolidation reactions. Such damage is usually so severe, that the affected building has to be partly or wholly demolished.

WTA specification 2-11-07 [2] serves well as a guideline for the rehabilitation of sulphatic masonry. Whenever the masonry is suspected of containing sulphatic components, the extant material must be subjected to extensive preliminary examination. Incorrectly repaired masonry can contain both sulphatic and hydraulic material, in which case markedly different repair materials are required.

The following solutions have often been applied to relevant renovation projects [3]: reduction of moisture exposure by sealing and replacing the mortar, closing cracks in the masonry, replacing the affected masonry, installing carbon straps, reinforced-concrete peripheral and internal tie beams (dry mix method), dry tie rods with abutments, and sock anchors.

No matter which repair measures are taken, direct contact between any sulphatic material in the masonry and any hydraulically reacting material in the moist environment must be effectively precluded. That is why practical solutions often remain elusive, or the proffered systems are not sufficiently robust for the complex structural situation.

Because of all this, two research projects were conducted at Bauhaus-Universität Weimar for the purpose of identifying alternative materials for use in rehabilitating masonry that has already suffered damage due to destroying minerals (Figure 1):

Reducing the formation of ettringite and thaumasite in damaged sulphatic masonry by introduction of silicic acid esters (SAEs)

Validation of a repair material for sulphatically and hydraulically bonded masonry

2 Reducing the formation of ettringite and

thaumasite in damaged sulphatic masonry

by introduction of silicic acid esters (SAEs)

The aim of this project was to develop a material based on silicic acid esters (hereinafter referred to as “SAEs”) which should inactivate the ongoing formation of destroying minerals due to the use of hydraulic material in the sulphatic masonry. Introduction of a silicic acid ester can retard further reactions causing formation of expanding minerals and, simultaneously, help achieve restabilization of damaged structural constituents. The project assumption was that, following hydrolysis and polymerization of the SAEs, the silicon dioxide, together with the available calcium hydroxide, would enable formation of secondary C-S-H phases. As a result, the portlandite content of the reaction products of the hydratation products decreases and its sulphate resistance increases. The silicic acid esters were introduced in liquid form with no water added, thus avoiding slip and loss of strength due to moisture penetration of the gypsiferous material.

2.1 Silicic acid esters

Five commercial-grade SAEs with different gel deposition rates were employed. The materials were neither elastified nor hydrophobized.

2.2 Testing of mortar with different cement contents

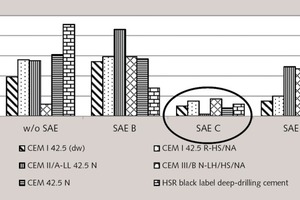

The addition of the specific SAEs to different mixtures of cement and gypsum yielded clearly differentiated results. The introduction of certain SAEs proved to reduce expansion within the hardened cement paste caused by secondary formation of ettringite. SAE C in particular appears to have a very positive impact regarding of expansion suppression (Figure 2). Here, the mineralogy phase composition was found to contain significantly less portlandite. However, it was not possible to clearly demonstrate the incorporation of silicon from the SAEs into the C-S-H phases. For one cement system to which SAE C was added, NMR scans showed a significantly higher Q2/Q1 ratio, which is indicative of stronger linkage of the C-S-H phases and a lower C/S ratio.

2.3 Strength and porosity

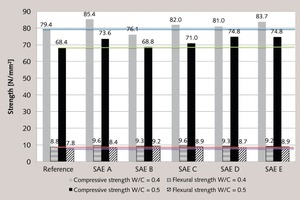

The use of SAEs enabled gains in the compressive strength of the tested specimens (Figure 3). A stain test was able to establish complete penetration of the specimens with SAEs. The capillary porosity was not significantly altered by the application of SAEs.

2.4 Chemico-mineralogical aspect

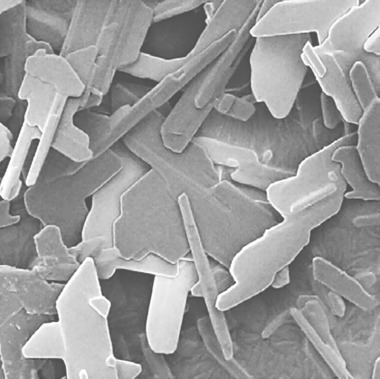

of SAE impact on hydrating calcium silicates

Adding small amounts of silicic acid esters, whether during in early phase of hydration or at some later point in time (in this case after 28 d of hydration), exerts an evident effect on the microstructure of the hydrating silicic primary clinker phases. Immediate addition of the SAEs delays hydration of the siliceous clinker phases. In case that no organic substances were detectable after two days of hydration. Apparently, hydrolysis and polycondensation take place very rapidly under such circumstances. Some SAEs hydrolyzed more slowly, if the SAEs were added later. Under such reaction conditions, the nature of SAE reactions appears to be distinctly dependent on the type of SAE in question.

Hydrating C3S specimens to which SAEs C and D were added (minor expansion) displayed significantly less portlandite than the reference specimens after 28 days of hydration. This is indicative of a higher rate of calcium consumption for the formation of new C-S-H phases.

2.5 Characterization of the SAE

“silica gel” reaction products

The results of the project show that the SAE reaction products causing less expansion in hardened cement paste display a higher O/Si ratio. This is indicative of looser linkage between the SiO4 tetrahedrons. In addition, SAEs react quite differently in an alkaline environment (corresponding to pore solution in concrete and mortar) than in a neutral environment. These phases are mostly richer in silicon and contain alkalis, which is a sign of a lesser degree of polymerization due to elevated pH during the polycondensation process. This predestines appropriate SAEs for application to an alkaline cement system.

2.6 Final assessment

Near-practice investigations are needed to verify the above theoretical findings and to satisfactorily solve the problem of the ettringite and thaumasite formation in systems containing both sulphatic and hydraulic constituents. Particularly for calcareous systems, the use of appropriate SAEs appears to work well in suppressing the formation of destroying minerals (thaumasite).

3 Validation of a repair material for

sulphatically and hydraulically bonded masonry

Within the framework of a basic research project, Bellmann [4] at Bauhaus-Universität Weimar developed a hydraulic binder that is compatible with both hydraulic and sulphatic materials. Building on that basis, a corresponding mortar system that remains stable in the aforementioned milieu was tested in a BMBF research project.

3.1 Laboratory testing

A number of masonry mortars with strength values conforming to MG II, MG IIa and MG III were prepared along with jointing, rendering/plastering, grouting and aerated grouting mortars. All these materials were first tested for durability. Gipsiferous mortars with different sulphate contents (5 to 50 wt% gypsum, 10 wt% CL 90, 2 wt% kaolin and 0-2 mm sand) were prepared, stored for 28 days under standard climatic conditions (20 °C, 65 % r.h.) and then crushed to a grain size of 0 – 8 mm. The thusly obtained sulphatic “aggregate” was then added (40 wt%; ) to the special fresh mortar mixtures after Dreuse/ Zier [5]). The prisms made from that material have now been in storage for over two years in a cloud chamber (20 °C, 100 % r.h.). Every 30 days, the expansion values of the mortar mixtures are determined. The maximum expansion noted to date was 0.8 mm/m for a mortar mixture comprising 50 % specialty mortar and 50 % sulphatic “aggregate”. Mixtures with up to 20 % sulphatic “aggregate” displayed less than 0.6 mm/m expansion. Even after more than two years of reaction time, no indication of phase change, e.g., formation of ettringite or thaumasite, was observed. This also applies in parallel to specimens stored in parallel for approx. 1.5 years at 8 °C and 98 % r.h. Nor was any internal microstructural damage detected by way of ultrasonic wave-velocity measurements.

3.2 Field testing

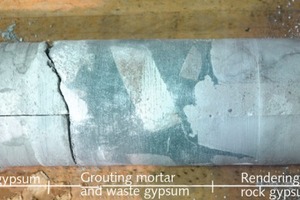

Building on these positive findings, multiple-leaf model walls were constructed of different materials (porous bricks, compact limestone, soft sandstone and rock gypsum, gypsum mortar and the specialty mortar used in the described system), and patterning areas were laid out on model objects. In the course of application under field conditions, the mortars showed themselves to be readily workable (Figure 4). Thanks to its very good fluidity, the injected grouting mortar enabled optimal void fill (Figure 4). The objects treated with the specialty mortar system have been under observation for over half a year now and still exhibit no sign of damage.

After an elapsed time of four months, an initial set of core samples were taken for the purposes of examining the distribution of grouting mortar and ruling out secondary formation of damaging mineral phases.

Again the grouting mortar was found to be well distributed (Figure 5), and no indication of secondary phase formation was observed in the vicinity of the contact zone between gypsum and grouting mortar (microscopy, phase analysis by X-ray diffraction, see also Figure 6).

The model walls and objects are subject to continuous visual inspection and regular, short-interval non-destructive (ultrasonic) testing. Additional sampling for the purpose of ruling out new phase formation is planned to be carried out at longer intervals.

3.3 Conclusions

The project findings attest to a very positive tendency. The mortar system presents an option for future renovation and restoration measures. As for now, this writing, the system cannot yet be generally recommended for all application situations. Damage caused by formation of expanding minerals results from time-dependent reactions. Despite all accelerated laboratory experiments (involving variations in temperature and humidity), it remains difficult to make any assertions with regard to the next one or two decades. Consequently, long-term monitoring of the model walls and objects is planned.

The article is based on a paper presented at the 3rd Weimar Gypsum Conference in Weimar, 14.03-15.03.2017.

Promoted by DFG and BMBF

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.