Raw materials characterization for industrial lime manufacturing

To meet the changing needs of different industrial sectors, various qualities of quicklime and hydrated lime are required. For this reason, an improved quality control in the calcination is necessary.

1 Introduction

Considering that different qualities of quicklime, and hydrated lime, have become needed to satisfy the new requests arising from...

1 Introduction

Considering that different qualities of quicklime, and hydrated lime, have become needed to satisfy the new requests arising from different industrial segments, it has been necessary to improve the quality control in the calcination process, starting from a complete set of analyses of the bulk rock material. The internal procedure for raw materials characterization, includes chemical, and physico-mechanical analyses, coupled with the burning attitude and technological tests. Recently, mineralogical-petrographic examinations, deriving from a geological expertise, have been also performed to evaluate the impact of compositional and microstructural parameters of carbonate rocks on the quality, and use of industrial quicklime. Especially, the X-ray powder diffraction analysis (XRD) has been performed using the Rietveld method to determine the quantitative phase analysis (QPA). Regarding the textural analysis, more correctly defined as petrographic, or microfacies analysis of carbonate rocks, the digital image processing technique has been adopted to determinate the micrite to sparite ratio (M/S), and the crystal-size distribution.

As concerns the burning attitude at different temperatures has been performed to predict the behavior of raw material in a TSR kiln using different kind of fuels. On the basis of all these tests, the raw material suitability report is provided.

Indeed the objective of this study is to show the relationship between compositional-microstructural parameters, physico-mechanical behavior, and burnability of carbonate rocks in the calcination process, in order to predict the impact on quicklime reactivity. Finally, advances in the characterization of industrial minerals, based on integration of different analytical techniques, can be successfully adopted in solving problems related to the calcination process, and in general, to modernize the entire lime sector.

2 Materials and methods

Physico-mechanical analyses, including bulk density, maximum moisture, approximately equivalent to the capillary porosity, and degradation test are performed on raw materials. The burning attitude of lime is evaluated in a muffle furnace, considering the ignition loss after a certain time at a certain temperature. The standard burnability test is approximately equivalent to the thermogravimetric analysis (TGA), but performed on bulk rock samples, and not on a powder. Concerning technological tests, the expansion test at 700 °C is performed to predict the clogging tendency of the carbonate rocks in the preheating zone of the kiln, while the high temperature test at 1300 °C, namely the overburning test, is performed to predict the stickiness of the lime during the maximum temperature in the kiln. After the thermal shock the color of the lime is also recorded.

Subsequently, the mechanical behavior of lime is evaluated by means of degradation and drop tests. For the degradation a standard sieving machine is used. This test simulates the rubbing action of the lumps of raw material and lumps of lime inside the kiln. During the descent of the material inside the kiln, a process, which typically takes 16-20 hours in a TSR kiln, stone surfaces will rub against each other and a degradation takes place. The result of the internal test is given both for the raw material and for the lime, and expressed as the percentage of material remaining on the 10 mm and 19 mm sieves. It is important to distinguish between the fines produced (fraction < 10 mm) and the amount of cracked lime (fraction between 10 and 19 mm). Sometimes, the raw material has a clear tendency to split into smaller lumps during the preheating or at the beginning of the calcination, whereas the lime itself can be strong. In this case we have a rather low fine fraction < 10 mm, but the amount of cracked lime between 10 and 19 mm is generally high. Such a raw material gives rise to a lower specific production of the kiln. The results of the degradation test, both for the raw material and the lime, are used directly as inputs for the mathematical model predicting the specific production of the chosen kiln. Moreover the drop test simulates the falling of the lime at the discharge of the kiln, and later the falling of the lime into the silos. Both these tests permit evaluation of the grain size distribution of the lime, and to match it with the requirements of different lime sizes requested by the clients.

It is important to be able to predict the reactivity of the lime produced in the industrial kiln. The reactivity depends on the characteristics of the raw material and the fuel used, but also on the heating rate in the preheating zone. This issue is complicated, and practical experiments in the laboratory are necessary in order to predict the reactivity of the industrial lime using that particular raw material, and that particular fuel. The reactivity of lime in steel making is performed using the coarse grain titration, according to an internal method. The reactivity of building lime is evaluated according to the European EN 459-2, or American ASTM C110-03, standards. The higher t60 time, the slower the reactivity. Subsequently, the quicklime reactivity is evaluated, as follows:

high reactivity: t60 is reached in 3 min. or less

medium reactivity: t60 is reached in 3–6 min.

low reactivity: t60 is reached in more than 6 min.

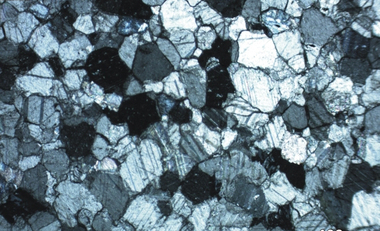

3 Compositional analyses

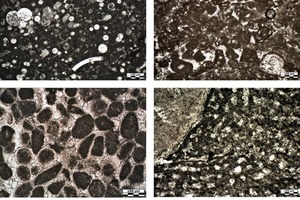

Chemical, mineralogical and petrographic analyses on representative carbonate rock samples are reported in Table 1. According to the petrographic classification of sedimentary carbonates proposed by Dunham [2], both mud-supported microfacies, namely mudstone/wackestone, and grain-supported ones, namely packstone/grainstone, are reported. Sporadically, reef-coralline boundstones are present, as well. Moreover diagenetic modified carbonate rocks, including sparry-calcite, saccharine dolomites, and granoblastic metamorphic ones (i.e. marbles), are present too (Fig. 3).

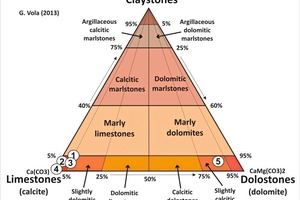

Another possibility for the classification of carbonate rocks is considering their mineralogical composition, in terms of calcite, dolomite and clayey impurity, as shown in Figure 4.

Mineralogical-petrographic analyses show that non-carbonate impurities are mainly ascribed to the presence of detrital quartz grains, feldspars, argillaceous, and opaque minerals, and, finally, organic matter. Different mineralogical constituents and textures reflect the wide range of geological origins, including different depositional, and diagenetic environments for the sedimentary rocks, i.e. microfacies, and P-T conditions for the metamorphic ones. A schematic profile of a carbonate platform, with the provenance of samples on the basis of their depositional texture, and fossiliferous content is shown in Figure 5 a. Subsequently, representative micrographs of the most important microfacies of the carbonate rocks samples are reported in Figures 5 b–g.

Considering the impact of composition and microstructure on the quicklime reactivity, some important parameters, such as the silica content (SiO2%), and the micrite to sparite ratio (M/S) for the calcitic and dolomitic limestones, have been plotted against the reactivity of quicklime burnt at 1050 °C. Preliminary data show that the higher the impurity, in terms of silica content (SiO2%), the lower the reactivity in terms of maximum slaking temperature (Tmax); moreover the higher the micrite to sparite ratio, lower the quicklime reactivity in terms of temperature rise (t60) (Fig.6).

According to previous authors [3, 4], the general trend is that mud-supported microfacies, presenting finer textures, are less reactive then grain-supported ones, considering identical conditions of calcination and sintering up to 1050 °C. Ongoing analyses on diagenetic, and granoblastic carbonate rock samples, will clarify the impact of the crystal-size distribution on the reactivity, considering that the performance of lime is strongly controlled by physico-mechanical parameters, and calcination conditions too [5, 6].

4 Physico-mechanical, technological,

and burning attitude tests

Concerning the burning attitude, the following technological tests are performed:

standard burnability at different temperatures

expansion test at 700 °C

high temperature test at 1300 °C, namely overburning test

The sticking tendency can be interpreted as a function of different compositional, and physico-mechanical parameters. Case studies show that the higher the silica content, the lower the sticking tendency; conversely the higher the M/S ratio, the higher the sticking tendency (Fig. 7).

Finally, reactivity has been studied as a function of the different physico-mechanical parameters, as well (Fig. 8). A clear inverse correlation between the maximum slaking temperature (Tmax), and the mechanical degradation of lime has also been observed.

5 Conclusions

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Twin Shaft Regenerative (TSR) kiln. A: simplified scheme from European Commission (2010) [1], modified); B: a simplified scheme of Cimprogetti twin shaft regenerative kiln (2012)](https://www.zkg-online.info/imgs/tok_bcb00ab08a850dd2d09e5c924e7fc2ab/w300_h200_x400_y274_101528223_f3e5aec482.jpg)

![3 Classification of sedimentary carbonate rocks according to [1]. Symbols legend: 1: sample from Germany; 2: sample from South Africa; 3: sample from UAE; 4: sample from Malaysia](https://www.zkg-online.info/imgs/tok_97fc6e9b6c8e2e8744264be583fc07b9/w300_h200_x400_y219_101528232_d8c7b15e4b.jpg)

![6 Quicklime reactivity as a function of compositional (a) and textural parameters (b) [8]](https://www.zkg-online.info/imgs/tok_68a6f9d31cd7cf225e29545bd3b540d1/w300_h110_x230_y55_101528231_39cf497a91.jpg)

![7 Sticking tendency, namely overburning test, as a function of compositional (a) and textural parameters (b) [8]](https://www.zkg-online.info/imgs/tok_fb49c6ec15eb69ff9a341aa8beb9a427/w300_h110_x229_y55_101528233_c781d898d5.jpg)

![8 Maximum slaking temperature vs. lime degradation test (a) and apparent density vs. maximum slaking temperature (b) [8]](https://www.zkg-online.info/imgs/tok_addb59212c5effca9fd7b9d0f074efcf/w300_h110_x227_y55_101528214_63e1f64ddf.jpg)