Overhauling a plate conveyor

1 Introduction

FB Ketten has realized a customized and low-cost solution for the replacement of a more than 50-year-old Beumer plate conveyor at Juracime, a cement producer in Switzerland. Juracime, the second biggest cement producer in Switzerland, was founded in Aarau in1882 by Rudolf Friedrich Zurlinden. Today, the company produces more than 1 million tonnes of cement per year in two plants in Switzerland. The cement factory in Cornaux was established in 1964 and produces high-quality cement, mainly used for structural and civil engineering.

2 Overhaul of the 50-year-old Beumer

plate conveyor

...

1 Introduction

FB Ketten has realized a customized and low-cost solution for the replacement of a more than 50-year-old Beumer plate conveyor at Juracime, a cement producer in Switzerland. Juracime, the second biggest cement producer in Switzerland, was founded in Aarau in1882 by Rudolf Friedrich Zurlinden. Today, the company produces more than 1 million tonnes of cement per year in two plants in Switzerland. The cement factory in Cornaux was established in 1964 and produces high-quality cement, mainly used for structural and civil engineering.

2 Overhaul of the 50-year-old Beumer

plate conveyor

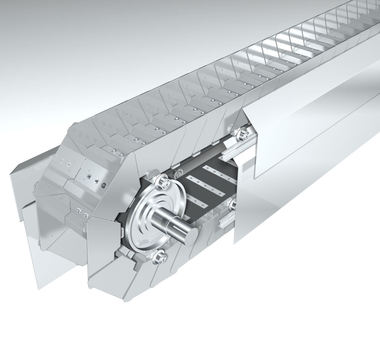

At the end of 2012 the Technical Head-Project Engineer, Marijan Pribanic, and the Technical Head-Engineer, Jürg Hitz, from Juracime’s Cornaux plant began planning the overhaul of their 50-year-old Beumer plate conveyor. This vital conveyor has been in operation at the plant since it was set up in 1964, and since then it has fed the plant with around 50 million tonnes of clay from the nearby quarry.

The plant’s plate conveyor has served the company well over the past 50 years but now the wear on the chain, the sprockets and the plates was too significant to guarantee safe operation and unplanned stoppages were becoming more frequent. The two project engineers were satisfied with the performance of the conveyor and wanted to revitalize it at the lowest possible cost, by replacing the wear parts like chains, plates, sprockets and chain rails.

3 Reference scraper chain in an E-filter

In 2010, FB Ketten had solved a lifetime problem in a forged scraper chain installed in an E-filter for Juracime Cornaux, which served as a good reference project for FB Ketten. Because of the corrosive working conditions, the lifetime of the original chains was only two years. FB Ketten installed a drop forged link chain with hardened stainless steel pins in 2010 and by February 2012 the chain was shortened by only 1 pitch of 142 mm. The FB drop forged chain is still in operation today and will run for at least another year. A lifetime of five years instead of two is a fantastic result for both Juracime and FB Ketten, bringing a high cost saving for spare parts and installation. Based on this good result, the decision-makers at Juracime knew that they could count on FB Ketten for a customized, low-cost solution that would meet their technical expectations.

4 High quality optimized solutions

FB Ketten technicians Daniel Zahnd from Switzerland and Thomas Wagner from Austria measured the existing installation and recalculated the chain. In December 2012, FB Ketten offered the replacement of the existing design and alternatively a proposal for an optimized chain solution.

Over the last 50 years there have been significant developments in chain design, materials and heat treatments. FB Ketten designed a plate conveyor chain and sprockets with functional dimensions that fitted the requirements of the existing housing, using today’s materials, construction and heat treatments to improve the quality, operational reliability and fatigue life of the chain and sprockets.

The FB Ketten link plates have been hardened and tempered to 350 HB and the bores for the link plates were produced by fine-punching. This offers the biggest possible contact area and a strong press fit between the round components and the link plates. The chain benefits from high resistance to shock loads and lateral loads during loading and operation of the conveyor.

The almost 1.6-m-long FB pins were produced from a high quality round bar. To reduce the wear, these shafts were induction-hardened in the bearing area – nearly twice as deep as the 50-year-old solution. The sprockets have also been improved. The wear area of the sprocket teeth has been induction-hardened to 55 HRC minimum and the hardness layer is a minimum of 3 mm deep – also deeper than the 50-year-old version. The optimized design and production quality are very important to achieve a long fatigue life of the chain, while the high quality of materials and the customized heat treatments are very important to reduce the wear of the turning components.

Juracime requested that costs be kept to a minimum by replacing only what was really necessary. Based on FB Ketten’s high application experience and product know-how. the company designed customized split, hardened sprockets. Thanks to the use of split sprockets, long and heavy shafts do not have to be dismantled. Conveyors are often installed in difficult-to-access places, a crane is rarely readily available in the facility. The split sprockets can be produced at low cost and saved a great deal of time and money as the almost 2-m-long heavy shafts did not have to be dismantled and then refitted.

To reduce wear, Daniel Zahnd improved the design of the side walls for the steel plates and used outboard rollers with maintenance-free ball bearings to lower the maintenance cost. Previously the outboard rollers had to be regularly lubricated through a lubrication nipple.

The staff at Juracime Cornaux were satisfied with the existing block chain structure that had worked for 50 years – one of the reasons Juracime decided on an improved FB block chain solution. Juracime still stocks some spare parts of the original solution. The FB solution guarantees that most of these spare parts will fit the new chain and do not have to be thrown away – another important cost saving for Juracime.

5 Experts in heavy metal

The Juracime plate conveyor chain was produced in the FB Ketjutekniikka factory in Finland. In May 2014, FB Ketten supplied more than 10 600 kg of chains, plates and sprockets to Juracime. One metre of plate-conveyor-chain weighed 480 kg – 25 times heavier than an average conveyor chain produced at FB Ketjutekniikka.

The installation for the new plate conveyor chain was organized by Juracime Cornaux, using a local long-standing partner based in Switzerland. In July 2014, Marijan Pribanic informed FB Ketten that the installation had been successful and the plate conveyor resumed operation.

//www.fb-ketten.at" target="_blank" >www.fb-ketten.at:www.fb-ketten.at

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.