Aumund Group equipment and solutions in the cement industry

Since the first pan conveyor for clinker handling was commissioned more than 60 years ago, Aumund Fördertechnik GmbH has become a recognized specialist for the conveying and storage of bulk materials, especially for hot and abrasive materials. The comprehensive product portfolio of Aumund and the Aumund Group of companies covers all aspects of bulk material handling and storage from the quarry to the dispatch of the finished product, including ship loading.

1 Introduction

Identifying technological trends, research, development, and innovation to suit the specific demands of plant operation, new process requirements and bulk materials are playing an important role in developing the Aumund Group’s reputation as a leading supplier of quality equipment with the highest technological standards coupled with a worldwide network of companies and agents, warehouses and an after-sales service around the globe.

2 Bucket elevators

The continuous and reliable transport of the raw meal to the cement kiln and the cement clinker from the kiln cooler to the silo and...

1 Introduction

Identifying technological trends, research, development, and innovation to suit the specific demands of plant operation, new process requirements and bulk materials are playing an important role in developing the Aumund Group’s reputation as a leading supplier of quality equipment with the highest technological standards coupled with a worldwide network of companies and agents, warehouses and an after-sales service around the globe.

2 Bucket elevators

The continuous and reliable transport of the raw meal to the cement kiln and the cement clinker from the kiln cooler to the silo and onward from the silo to the mill is fundamental to the efficiency of cement production in every plant regardless of size or production capacity.

The Aumund type BWG vertical belt-bucket elevator raises the raw meal from blending silos below to the pre-heater tower where the material is pre-calcined before being passed into the rotary kiln for final calcination and formation of the cement clinker (Figure 1). For larger plants, these elevators are installed with a single vertical lift in excess of 150 m.

Like all other Aumund products the type BWG vertical belt-bucket elevator has been subjected to continuous detailed development over the years and now represents the state of the art in this field of application. Unique to the Aumund system the type BWG elevator uses a single or double rope strand cross stabilised steel cord conveyor belt with close pitch cords to maximise the belt strength with a reduced belt thickness allowing selection of smaller pulley diameters to minimise gearing size.

In addition, compact close pitch buckets are employed to reduce the fixing stress and, combined with the special fixing design and close cord pitch, bucket detachment in service is virtually eliminated. To accommodate the high puncture strength of the cross stabilised close pitch steel cord belts Aumund have developed a special punching machine allowing the belts to be easily and reliable prepared before shipment (Figure 2).

3 Pan conveyors

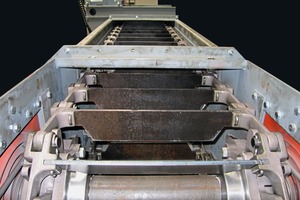

Aumund offer a wide range of clinker transport designs all based on a common set of conveyor chains and supporting wheels but with various pan arrangements depending upon the installed angle (Figure 3).

Handling for example hot material, the standard Aumund type KZB design without internal baffles is suitable for a working angle to 30 degrees. For steep inclines to 40 degrees the KZB-Q design with baffles provides a simple and effective solution and for even steeper angles the Aumund bucket conveyor type BZB is available (Figure 4).

Invariably the pan conveyors are usually installed in enclosed galleries for weather protection and environmental pollution control. Aumund offer a complete service from a full package including the conveyors, gantries, transfer towers and cladding or a simple engineering only package where key components are supplied but the client is free to arrange local fabrication for the heavy structures.

The classical KZB pan is designed with overlapping base plate and joggled side plates designed to ensure the material is effectively contained whilst allowing the conveyor strand to articulate around the terminal sprockets with minimum leakage. The unique side plate design ensures material does not become trapped between the adjacent pans causing premature wear.

For the steep angle BZB “bucket conveyor” design the material is conveyed in fabricated buckets with overlapping front and back plates to prevent spillage, as illustrated below.

Aumund has a wide range of conveyor chains formed in precision laser cut fine grain steels with an extended range and increased rupture strength allowing longer single flight conveyors. Often the traditional intermediate transfer tower may be completely eliminated and the clinker transferred direct from cooler to silo if the plant geometry permits.

Where vertical elevation is required then for handling hot materials such as cement clinker and other raw materials or additions the central chain bucket elevator type BWZ is the favoured solution in any critical application.

Suitable for handling materials up to 400 °C and with vertical lift height to over 70 m these machines are extremely robust and reliable, proven in continuous duty applications running 24/7.

Available with either a single bucket strand and suitable for handling rates to 800 t/h or with a double strand to 1600 t/h the range of options covers most applications including raw material intake to storage and mill recirculation.

The central chain system is based on a forged chain design with extended pins which carry loose bucket brackets mounted back to back and thus effectively retaining the bucket to the chain without a rigid bolted fixing. This loose bucket fixing is an Aumund patent and eliminates transmission of vibration and thus stress cracking of the bucket mounting is almost eliminated with a corresponding increase in bucket life.

The forged chains have an integral labyrinth seal and the bolt and bush are pre-lubricated on assembly. The seal substantially prevents ingress of material to the chain bush/bolt interface and the pre-lubrication promotes the development of a high quality surface finish to the bearing areas in service reducing the wear rate and consequently extending the chain life. The equipment described here covers the key areas in the transfer of material between the core processes in the cement plant and is therefore critical to the plant performance and profitability. Clearly an unscheduled kiln stoppage is disastrous with the attendant loss of production and re-commissioning costs but it is exactly the same story if the raw meal elevator or the clinker transport fails since the kiln is stopped just the same.

With a new plant or plant extension the operator is free to choose the equipment best suited to the application but for existing plants with life expired conveyors choices are more limited.

4 The Aumund three steps

solution for retrofit & conversion

With the Aumund Retrofit & Conversion solution new chains, pans or buckets, drive wheels and shafts may be applied to existing structures upgrading the equipment to the legendary Aumund standard of performance and reliability, for minimum investment (Figure 5).

As an example the plant illustrated above at HeidelbergCement Ennigerloh/Germany, an existing steel plate conveyor installed by another company was replaced with an Aumund BZB bucket conveyor within the same gallery and general operating envelope.

5 Heavy duty feeders

The Aumund BPB-SF heavy duty feeders receives mined limestone direct from off-highway trucks providing a controlled feed rate to the primary crusher generally located at the quarry; one of the toughest jobs in the conveying process (Figure 6).

Feeders are really the unsung heroes of the cement plant often working away year after year with little attention handling the full range of process materials and fuels and in primary feed applications sustaining huge impact loads from boulders of several tons in weight falling up to 10 m from the off highway type truck. In these ultra-high impact situations the plate feeder is really the only option, generally using tracked vehicle type chains up to 3600 kN rating with track rollers at short pitch to support the load and absorb the impact from falling rocks.

Available with plate width to 3000 mm and plates to 80 mm thick these Aumund type BPB-SF really are designed for arduous applications for long term reliability. Plates have milled edges for close fitting controlled overlap and cranked side boards to minimise risk of spillage. The close pitch supporting rollers are the key to long and reliable operation providing proper support for the chains and apron plates and distributing the load through to the feeder chassis.

These feeders are installed under steel or concrete hoppers often of several hundred tons capacity and will take material from the largest dump trucks (Figure 7).

Generally the apron feeder will discharge direct to the primary crusher inlet and must be speed controlled to allow critical optimisation of the crusher performance.

Hydraulic speed drives may be supplied with a remote power unit including variable flow axial piston type pump and motor combination providing adjustable speed control allowing fine-tuning of the feeder discharge rate.

As an alternative the modern design of electronic inverter speed system provides excellent control using a simple direct coupled electric motor drive with combination of helical and planetary reduction gear as illustrated below (Figure 8).

Both hydraulic and electronic variable speed systems may be supplied with a digital interface allowing the speed to be set remotely. Generally the crusher drive will have a current monitoring system linked via the main plant PLC to the feeder drive to ensure that the crusher is always operating at optimum efficiency.

Most primary crushers are very large installations weighing in at perhaps over 1000 t and requiring a substantial height differential between intake and discharge and as such are generally fixed at a central point within the quarry to minimise haulage distance.

Whilst off highway trucks have improved their fuel efficiency they remain very expensive both to buy and operate in today’s high fuel cost environment. Nevertheless the flexibility offered by truck haulage, particularly over short distances, is very attractive and generally this is the only viable solution to move material from the working face to the primary crusher. However, the economics of conveyor haulage are also very attractive but there are limitations on the use of belt conveyors and obviously it is not practical to convey the as mined material direct from the face. Clearly combining the low operating cost of overland belt conveyors with the flexibility of short haul truck operations would be the ideal solution.

6 Samson material feeder

Aumund have solved this problem by combining a Samson type mobile surface feeder with a twin shaft rotary sizer. In this manner as mined material may be reduced to a size that may be efficiently handled by overland belts.

The sizer is mounted directly over the field conveyor using a sub-chassis carried on rails allowing the sizer to be easily moved along the conveyor to the closest point to the working face (Figure 9).

The mobility of the Samson Surface Feeder is the key to this operation by providing a low level tipping point for the dump trucks and eliminating the traditional high level access ramp. Whilst the Samson will handle as mined material to a lump size of around 600 to even 800 mm there are limitations in truck size and material type but within reasonable bounds this is an excellent solution.

By introducing a simple belt weigher on the following conveyor the input rate to the plant may be closely regulated by adjusting the conveying speed of the Samson to achieve the required rate. The load within the Samson is monitored by load cells and the output signal used to control the main intake plate feeder to ensure the system is not overloaded regardless of the material characteristics.

Within the cement plant there are many applications for feeders and the Aumund Group have appropriate solutions for each and every section of the plant. For material additions and imported clinker again the Samson is an attractive solution as illustrated below at the TDCIM grinding plant near Sines/Portugal. Being surface mounted this is an economical and flexible solution minimising foundation costs (Figure 10).

7 Pan conveyors

In addition to conventional conveying the construction of the KZB pan conveyor can be applied to feeders particularly for the extraction of materials such as clinker from long hoppers below railcar intake (Figure 11).

In this application clinker is extracted from the under rail hopper and inclined up for transfer to an Aumund BWZ vertical bucket elevator for subsequent storage. Whilst the KZB design is ideal for handling dry materials such as clinker it is not the best solution for wet and sticky clays and marls which would adhere to the pans.

For these highly cohesive materials the type BPB arched plate design was developed with a smooth conveying surface which may be cleaned by suitable scrapers at the point of discharge (Figure 12).

Typically used for the extraction of raw materials and material additions from blending silos the Aumund BPB and BPB-S are proven and robust solutions (Figure 13).

In this case the silo outlet is formed into a rectangular slot taking the circular silo to the rectangular inlet of the feeder. As with the primary crusher feeders these silo discharge feeders are generally linked to an inverter speed controller to allow remote and automated discharge rate integration to the plant process demands.

Typically the feeder is supplied as a fully or at least partially pre-assembled package that may be simply connected to the prepared silo flanged outlet (Figure 14).

Both the pan and plate feeder designs may be supplied with integral weigh rails providing a mass measurement of output rate particularly for proportioning feeds and blends from multiple silos (Figure 15).

As illustrated above, an integral weigh rail supported on load cells carries the external pan or plate rollers allowing the material mass within the conveying element to be accurately measured dynamically. By computing the load on the weigh rail, the length of the rail and the speed of the conveyor, the discharge rate from the silo can be accurately determined.

In the project for TXI Oro Grande Cement four silos provide storage for additives which must be metered at the required tonnages to blend into the main mill feed system. Similar equipment is also presently in operation at the St. Genevieve plant in Missouri by Holcim.

This state-of-the art, environmentally-responsible cement plant will produce approximately 4 million t of cement per year to meet the demand of the internal US market. In addition to the weigh feeders Aumund supplied clinker transports, vertical elevators, silo dischargers and chain conveyors for this most important project.

In addition to the intake of as mined raw material and the discharge of silos the Aumund range of plate and pan feeders are equally suitable for forming an intermediate feed point for use with loading shovels discharging to existing overland or transfer belt conveyors (Figure 16).

As illustrated above an Aumund type BPB-S Apron Feeder receives clay from large shovels incorporating a buffer hopper and a controlled discharge rate using a rotary picker to regulate the discharge.

For the fine control of silo discharge rates cohesive materials such as wet clays are a real problem since the material tends to move as a block and shear off at the feeder discharge in large slugs creating peaks and troughs in the instantaneous output rate with the potential of bridging and blockage in the transfer chutes plus likely spillage from the ongoing belt conveyors.

Obviously the problem of highly cohesive materials is also very important in the design and construction of larger silos.

This is particularly true of materials such as F.G.D. gypsum (synthetic gypsum) as a replacement for natural gypsum but any fine and potentially wet material can be a real problem to extract reliably from large diameter storage silos.

In this situation the conventional cone or slot shaped silo outlet may not give reliable flow and with the risk of bridging and blockage or “Ratholing” causing an effective reduction of the silo usable working capacity.

A typical silo storage facility is illustrated above at the CBR cement plant in Ghent, part of the HeidelbergCement Group. In this installation the silos are fitted with the Louise BEW-K extractor system as illustrated below (Figure 17).

The Louise BEW-K is based in principle on the Aumund/Louise Centrex concept comprising a number of logarithmically shaped arms mounted to a rotating carrier which itself is mounted to a slewing ring allowing the carrier to rotate beneath the silo using a hydraulically operated circular rack system with twin actuators. In this manner the rotating arms excavate material from an undercut around the silo periphery working their way continuously around the silo circumference ensuring the contents are evenly discharged without risk of bridging or blockage.

Since the material is recovered from the outside of the silo reliable mass flow is ensured and the contents are discharged on the basis of first in first out always. In addition to the Samson plus the plate and pan feeders described here where the material load is effectively carried on rollers there is also the chain scraper conveyor type feeder known as the Aumund PKF armoured chain conveyor and the Aumund TKF drag chain conveyor.

The type PKF is generally used for handling difficult material beneath truck dump hoppers or more often under rail intake hoppers and has particular advantages in this situation. The PKF is very compact and fully sealed eliminating any risk of spillage or dust escape.

Since these feeders are generally installed in deep pits housekeeping issues are important since clearing away spillage is difficult, expensive and time consuming (Figure 18).

Illustrated above a typical PKF installation under an intake hopper providing a controlled discharge rate to an ongoing conveyor system.

With its low construction height the armoured chain conveyor is primarily used for hopper discharge of crushed limestone or sticky raw materials such as chalk, gypsum, marl, clay or coal. Illustrated above during assembly and including a rotary picker at the discharge.

Available with a conveying width of up to 2600 mm the PKF can handle up to 1800 t/h depending upon the material type.

In addition to the PKF Armoured Chain Conveyor the type TKF Drag Chain Conveyors may also be used as feeders beneath silos and rail hoppers where the material specification permits.

The TKF is a long-standing Aumund Group product with over 650 units installed worldwide handling raw materials, additions and fuels, both for feeding and transfer (Figure 19).

The TKF is also a fully enclosed design and as such spillage and dust generation are eliminated making this a clean solution ideal in confined spaces. Naturally cleanliness in operation is important in any situation and whilst the PKF and TKF designs have particular attributes in this respect it is not the only solution. There are many applications where the apron feeder is the only viable option but by definition the apron design has issues with cleanliness and material carry-back adhering to the apron plates is very difficult to completely eliminate.

In this situation a spillage returns conveyor prevents any spilt material falling outside the confines of the conveyor system by collecting material falling from the pans on the return side; as illustrated on this weigh pan feeder shown below (Figure 20).

As referred previously in many of the applications described here the rotary picker device is employed to loosen the bulk material as it passes over the discharge point of the feeder and thus smoothing the discharge rate. This is a key feature for handling difficult materials without which the equipment would not function properly particularly when handling low volume rates.

In all applications feeders have to sustain heavy material static and impact loads and as such are exposed to far higher stresses compared to general transfer conveying within the cement plant process.

Not only are feeders expected to operate in these extreme conditions handling the regular materials used in the cement industry. A whole new raft of special alternative fuels and substitute raw materials with handling characteristics far away from the general experience can be found.

Aumund continue to develop the range of feeders and with the addition of the Samson type from Samson Materials Handling (Aumund Group) are now able to offer solutions suitable for these exotic fuels and raw materials.

Naturally all machines eventually require some attention and Aumund offer a fully comprehensive after-sales and refurbishment service (Figure 21).

As illustrated above an existing plate feeder is in the process of upgrading to the Aumund BPB-SF specification with new conveyor chains and apron plates.

Generally most existing machines may be upgraded to the Aumund specification by our experi-enced team of site engineers enabling the user to enjoy the legendary Aumund reliability and service without the cost and downtime of a full feeder replacement. Experience is the key to reliability and performance and in this Aumund have the products and the know-how to deliver the appropriate design for all applications.

//www.aumund.com" target="_blank" >www.aumund.com:www.aumund.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.