New binder technology for 2K fast curing waterproofing membranes

The fast curing of a membrane is an important attribute for the waterproofing market because it offers the applicator the possibility to apply a second waterproofing layer and go to the following step in the construction within the same working day. A new generation of latexes developed by Dow Construction Chemicals combined with a fast curing drymix helps achieve very good waterproofing performance at standard and high pressure, very high flexibility and crack bridging, as well as elongation retention after water swelling.

A drymix formulated with fast cement and combined with standard latex results in a very short pot life mortar and a membrane that lacks flexibility and very often has cracks and hence is not waterproof. The new latexes provide long enough pot life to allow good workability and still enabling the application of a new layer on top of the first layer within 0.5–2 h. This new technology will provide the waterproofing market an environmentally advanced option for both interior and exterior applications.

1 Introduction

Faster curing waterproofing membranes can be achieved by using fast setting cement...

A drymix formulated with fast cement and combined with standard latex results in a very short pot life mortar and a membrane that lacks flexibility and very often has cracks and hence is not waterproof. The new latexes provide long enough pot life to allow good workability and still enabling the application of a new layer on top of the first layer within 0.5–2 h. This new technology will provide the waterproofing market an environmentally advanced option for both interior and exterior applications.

1 Introduction

Faster curing waterproofing membranes can be achieved by using fast setting cement like calcium alumina cement (CAC). However, there are multiple challenges when using emulsion polymers in fast setting cement compositions. As the wet mortar thickens very fast, the applicability and workability becomes very difficult; pot life is unacceptably short and the resulting membrane is too rigid, and thereby lacks flexibility and often cracks so that it is not waterproof. Further, in fast setting compositions, the emulsion polymer does not provide enough flexibility to give sufficient crack bridging in dry/wet conditions. One way to solve the problem of the rigidity of the resulting membrane would be to reduce the glass transition temperature (Tg) of the emulsion polymer, making it softer and more flexible, and/or to increase significantly the polymer to cement ratio. In both cases the solution impacts the membrane cost.

An effective fast curing sealing membrane would enable the applicator to apply a first and a second layer within the same working day. If the application is in a basement – as a replacement of bitumen – the next step in construction could follow after 24 h instead of several days later.

The present study has sought to solve the problem of providing a two-component composition of a fast curing drymix and an emulsion polymer additive that makes a wet mortar composition suitable for use as a fast curing waterproofing membrane without significantly reducing the Tg of the polymer or increasing the polymer to cement ratio in the composition, while enabling both acceptable mortar pot life and flexibility in the final cured membrane so that it does not crack while curing.

2 Materials and test methods

2.1 Materials

The latex samples of the present study have been tested in the drymix formulation described in Table 1. The main properties of the latex binders tested are summarized in Table 2.

2.2 Test methods

2.2.1 Preparation of the membrane mixture

The liquid components are weighed into a beaker and mixed for 30 seconds at 200 rpm. The well mixed dry components are added carefully under stirring within 45 seconds. When all solid components are added, the slurry is stirred at 700 rpm for 2 min15 sec.

2.2.2 Pot life/viscosity increase

The freshly prepared membrane mixture is immediately transferred into a steel beaker. The steel beaker was jolted five times by hand and then the surface was smoothed with a scraper. By weighing the steel beaker the density is determined. 30 seconds after the beaker is filled the viscosity is measured the first time. This measurement will be done also after 5, 15, 30, 45, 60, 90 and 120 minutes. The viscosity is measured with a Brookfield RVT DV-II viscometer at 5 rpm with a T spindle on a Helipath stand at 23 °C/50 % RH.

2.2.3 Cement setting with ultrasonic tester

The freshly prepared membrane mixture is put into the testing chamber. An ultrasonic pulse will be sent from the transmitter to the receiver and the speed will be recorded. As the membrane becomes harder, the sound travels faster. The setting will be measured over seven days.

2.2.4 Water impermeability according to EN 12390-8

Prepare a limestone brick with a drilled hole on the obverse side of the testing surface. The freshly made membrane mixture is applied at 1.3 mm thickness in one layer on the limestone brick. After 4 h a second 1.3 mm layer of a freshly made membrane mixture is applied on the first layer. Let it dry for seven days at 23 °C and 50 % RH. Put a water indication paper into the drilled hole. The membrane with the limestone is put into the water impermeability tester and a hydrostatic pressure of 1.5 bars is applied on the membrane for four days. If the water absorption is less than 25 ml raise up the pressure to 5 bars. If the absorption is higher than 25 ml, hold the pressure an additional three days at 1.5 bar. After seven days the water indication paper will be checked. The test is passed if no humidity is seen underneath the membrane. In parallel the water loss over time is read from the calibrated cylinder of the water impermeability tester.

2.2.5 Elongation and tensile strength measured according to DIN ISO EN 527-1 and DIN ISO EN 527-2

Two different curing conditions are applied. The first one is curing of the membrane at 23 °C/50 % RH for seven days and the second one curing for seven days at 23 °C/50 % RH and additional seven days under water (23 °C). Curing time was shorter than usual (28 d or 7 d + 21 d under water) because the comparison data were needed as soon as possible. In a known formulation the data after seven day curing are good enough for comparison purposes. Optionally the elongation and tensile strength can be measured at -5 °C and -20 °C. The freshly prepared membrane mixture is applied at 2.6 mm thickness in one layer onto a Teflon film. The membrane is cured for seven days at 23 °C/50 % RH. After curing 14 specimens are cut out from each membrane. Half of the specimens are immersed into water for seven additional days (23 °C), the other half are measured immediately. The specimens for the water immersion test would be tested wet. Elongation and tensile tests are run in a texture analyzer at a speed of 20 mm/min.

2.2.6 Crack bridging according to EN 14891

For this test concrete specimens (160 x 50 x 12 mm) are homemade according to EN 14891 from fresh mortar. The freshly prepared membrane mixture is applied with a metal frame of 3 mm thickness on one of the 160 x 50 mm sides of the concrete specimen and let it dry for 4 h. Then new freshly prepared membrane mixture is applied on the other side of the specimen using the same frame. The membrane is cured for 7 or 28 days. After curing time the concrete specimen is broken carefully. The broken concrete specimen with the intact membrane is elongated with the texture analyzer at 0.15 mm/min. The surface of the membrane is monitored visually. The distance is reported when (A) at maximum force (B) the first cracks appear. Additionally the maximum force is reported. For measures at low temperature, specimens would be stored over night at the -5° C or -20 °C.

2.2.7 Static crack bridging according to EN 1062-7

For this test hydrophobic concrete specimens (160 x 50 x 12 mm) are used. On the reverse side there is after 80 mm a 3 mm deep gap as a rated break point. The freshly prepared membrane mixture is applied with a metal frame of 3 mm thickness on the top side of the concrete specimen. The membrane is allowed to cure for 28 days. After curing time the concrete specimen will be fixed in a special bent equipment to break the specimen over a wanted angle to get a gap of 0.4, 0.75 or 1.5 mm at the rated break point.

The crack of the membrane at the rated break point is monitored visually by grading:

Grad 1: no crack

Grad 2: white break

Grad 3: thin crack not passing over total wide

Grad 4: thin crack > 1 mm

Grad 5: crack < 1 mm

Grad 6: immediately crack after breaking

This test can be done also at low temperature. In this case there will be a cool down to the needed temperature for least 3 h before breaking over the wanted angle.

2.2.8 Adhesion strength according to EN 1542

The freshly prepared membrane mixture is applied at a thickness of 2.6 mm onto a hydrophobic concrete slab. Adhesion is measured after:

(A) 7 days and 28 days storage at 23 °C/50 % RH

(B) 7 days storage at 23 °C/50 % rel. humidity and 21 days in water

(C) 14 days at 23 °C/50 % RH and 14 days at 70 °C (air circulation) additional 1 day at 23 °C/50 % RH

3 Results and discussion

The evolution of a cement paste from a soft material to a hard solid occurs in several stages. By designing the right latex, the aim is to control the correlation between cement hydration and cohesion evolution of the final composite – flexible membrane – in that case. When cement is mixed with waterborne latex, each cement phase dissolves at least partially, leading to the establishment of a supersaturated solution with respect to the different hydrates, which can precipitate [1]. But in order to obtain a rapid hardening and a rapid drying a hydraulic binder mix containing Calcium Aluminate Cement (CAC) in combination with Portland Cement (OPC) and/ or Calcium Sulphate (CS) is required. It has been found that the early hydration reactions are always dominated by the ettringite formation – aluminum, sulphate and calcium ions in solution [2]. The formation of ettringite results from nucleation and growth from solution. The chemical reactants – aluminum, calcium and sulphate ions in – come from the dissolved solid mineral constituents for which the equilibrium solubility constant is Kett = 4.9 x 10-44. The rate of nucleation and growth of crystals depends, amongst others things, on the supersaturation coefficient β which is related to the energy available for the formation of the nuclei that in the case of ettringite is [3]:

6Ca2+ + 2Al (OH)-4 + 3SO42- +4OH- + 26H2O

➞ 3CaOAl2O3 · 3CaSO4 · 32H2O⇥(1)

β = (a Ca2+)6 · (a Al(OH)4-)2 · (a SO42-)3 ·

(aOH-)4/Kett⇥(2)

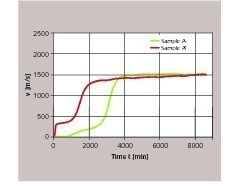

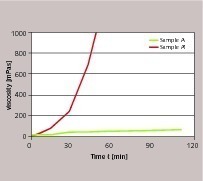

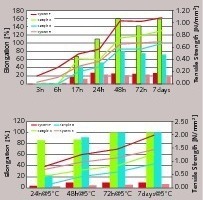

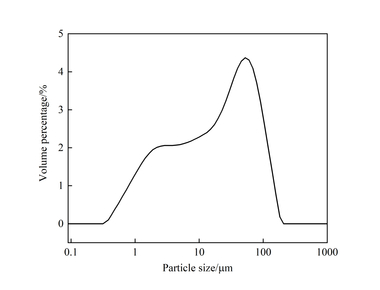

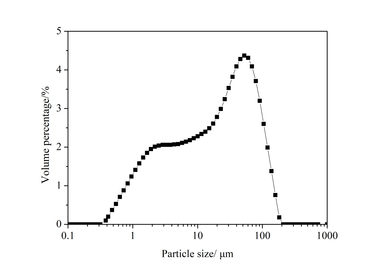

The “a” coefficients are the ion activity (which is the ion concentration multiplied by the activity coefficient γ). For crystallization to occur β must be greater than one. Kinetics of nucleation depends strongly on the concentration of calcium ions in solution and fairly strongly on the hydroxyl ion concentration or pH of the media [4]. With the right latex design it would probably be possible to control the different ion activity and hence growth conditions of ettringite formation which result in different crystal morphology and crystal quantity that will strongly influence the mortar properties. The two latex samples A and A’ (which composition is summarized in Table 2) have an identical backbone but they have been produced following different processes: The hypothesis is that when mortar slurry is prepared using sample A, β < 1 while with sample A’ β > 1. In Figure 1 and 2 could be observed the difference in wet mortar behaviour; speed of nucleation phase while measuring cement setting and pot life of membranes prepared respectively with sample A and A’.

Both cement setting and pot life for sample A’ are extremely fast and result in a very rigid, non-cohesive membrane due eventually to a too fast/uncontrolled crystallization of ettringite during nucleation phase, while sample A for which pot life and also setting profile are much longer, provides a highly flexible membrane. As indicated in Table 1, Tg and polymer backbone for sample A and sample A’ are identical. This is therefore clear evidence that a low polymer’s Tg is not enough to guarantee good flexibility.

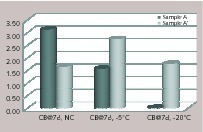

The previous statement applies at room temperature but as shown in Figure 3, to obtain deformation at low temperature (-20 °C), a very low Tg is necessary. Only sample B, with Tg -30 °C, provides deformation at -20 °C. Both sample A and B have been produced following the same production technology especially adapted to fast drymix systems.

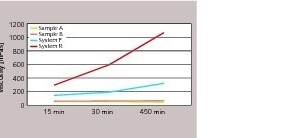

As mentioned in the beginning of this report the aim of the project was to develop a binder that combined with a fast drymix would enable applicators to work long enough with wet slurry, resulting in sufficient pot life and at the same time to develop strength fast enough to be waterproof as soon as possible. Figure 4 shows pot life data of the two binders developed (samples A + B) with the new technology compared to commercially available fast systems (samples F + R). The tested systems are building up viscosity slower than the commercially available one. However, when we look at the early strength development both at water impermeability results as shown in Table 3, and also in terms of elongation/tensile at low temperature over time, as presented in Figure 5, we could confirm that the new technology provides superior performance in absolute terms of timing and mechanical strength compared to commercially available systems.

Results are self-explanatory and we could state that after 24 hours both at room temperature and at 5 °C the membranes prepared with the new binders have developed more than 80 % of the total mechanical strength and the absolute value is so high, that membranes are already water proof even under the highest pressure conditions.

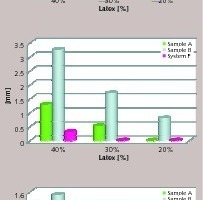

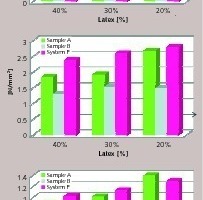

Another important attribute that the 2K waterproofing market expects from a binder is efficiency. If one takes a very low Tg pure acrylic binder and loads a high dosage of polymer, it is possible to get the desired outcome but at a very high price. The outstanding mechanical strength values in terms of elongation and tensile at room temperature with sample A and at very low temperature with sample B enables each a very efficient system.

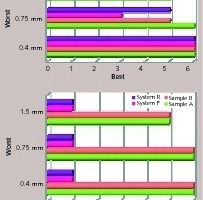

As shown in Figure 6 and Figure 7, the EN-14891 crack bridging and adhesion standard can be reached at lower latex dosage compared to commercially available systems. When the membrane is used in basements or as concrete protection, the required standard is EN-1504-2 in which flexibility is measured following static crack bridging. This test, in particular at low temperatures, is very difficult to pass when the membrane is prepared using a fast drymix. Figure 7 presents the static crack bridging results of sample A and B in comparison to system R and F using commercially available binders. It could be shown that the technology helps to achieve significantly improved results.

The results showed a significant difference, in particular at low temperature. The new latex technology will enable formulators to produce fast curing membranes with a differentiated performance.

4 Conclusions

With a new latex technology the control of the β initial nucleation phase enables superior mechanical performance of the final membrane during cement hydration in a ternary binder system. The Tg and polymer backbone are not sufficient parameters to predict performance of a cementitious membrane. A very low Tg (< -20 °C) and a right polymer backbone are critical to develop crack bridging at -20 °C. The new technology supports formulation of differentiated 2K fast curing waterproofing membranes for which flexibility is a key parameter under extreme conditions, providing highest performance of static crack bridging in particular at -5 °C. The new latex technology imparts simultaneously long pot life and early strength development at low temperatures. It helps achieve waterproofing capability after 24 hours at 5 °C and has shown especially high latex efficiency.

Acknowledgements

This project has been accomplished thanks to the highly valuable contribution of Andreas Mueller, Ann Evans, Jouko Vyorykka, Sia Yiu, Marc Schmitz, Sudhir Mulik and Nolwenn Colmou.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.