Lean Six Sigma to improve a cement

production process

Nationwide, companies in various industrial sectors are implementing Lean Six Sigma (LSS) in order to reduce the requirements and cost of production, to increase customer satisfaction and to improve product quality. LSS is not merely a business improvement tool; it is a philosophy that needs to be driven from the top team down if it is to generate the required levels of understanding and belief. The application of the DMAIC (Define, Measure, Analyze, Improve and Control) phases of LSS to a “cement production process” is described in this article.

1 Introduction

The cement industry is known as one of the most energy-intensive industries, consuming a quarter of the total world energy. To combat the increasing energy and material costs, cement companies need profitable solutions to secure a competitive advantage.

Many industrial companies are searching for management methodologies that enable them to improve their products and/or service characteristics, perfect their processes, reduce costs, improve profitability and customer satisfaction. Lean Management and Six Sigma are the two accepted methodologies that underlay continuous...

1 Introduction

The cement industry is known as one of the most energy-intensive industries, consuming a quarter of the total world energy. To combat the increasing energy and material costs, cement companies need profitable solutions to secure a competitive advantage.

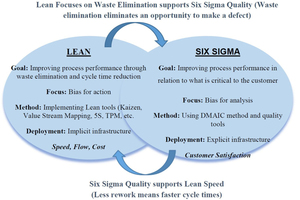

Many industrial companies are searching for management methodologies that enable them to improve their products and/or service characteristics, perfect their processes, reduce costs, improve profitability and customer satisfaction. Lean Management and Six Sigma are the two accepted methodologies that underlay continuous improvement approaches for the managerial and production processes. Lean management focuses mainly on the creation of value through the relentless elimination of waste (non-value-added activities), using simple and visual techniques whenever possible and Six Sigma focuses on the control and process variability reduction, using statistical tools for this purpose.

The objective of this project focuses on the identification of potential to optimize the cement production process with the use of Lean Six Sigma bases. Lean Six Sigma is a method of improving quality and profitability based on mastering the process statistically and it is also a management style that is based on a highly regulated organization dedicated to managing the project. The method is based on five main phases, that is: define, measure, analyze, improve and control (DMAIC).

2 Lean Six Sigma framework

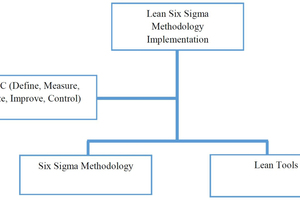

The Lean Six Sigma methodology used to improve the performance of the process is represented schematically in Figure 1.

The American Society for Quality defines Lean Six Sigma as a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time, while promoting the use of work standardization and flow, thereby creating a competitive advantage. It applies anywhere where variation and waste exist, and every employee should be involved [3].

Lean Six Sigma is a business improvement methodology integrating Lean and Six Sigma that are two distinctive management philosophies, complementing each other so as to improve enterprise processes and results. This integration has been achieved by blending their methods and principles using the DMAIC (define, measure, analyze, improve, control) cycle as the conjoint continuous improvement framework and conjointly making efforts to reduce production defects and process variability along with process simplification and standardization and waste reduction [4]. Integration of Lean and Six Sigma is illustrated in Figure 2.

For DMAIC phases of Lean Six Sigma, Lean tools are used during the different phases of the process to integrate the Six Sigma methodology.

3 Implementing DMAIC methodology

in a cement company

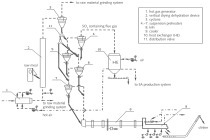

The cement production process is basically a two-step process. In the first step, clinker is produced from raw materials. In the second step, cement is produced from cement clinker. In this project, the process is divided into three steps: first, raw meal is prepared from the raw materials; second, clinker is produced from the raw meal and the third step is the production of CEM I 42.5 R type Portland cement by grinding the clinker together with gypsum (without minor additional constituents).

The overall goal of this study is to show how implementing DMAIC methodology can improve the performance and the efficiency of the cement production process to obtain stable early strength and initial setting time of CEM I 42.5 R type Portland cement.

3.1 Define phase

In the cement industry, the aim is achievement of optimum quality combined with maximum production rate. It is critical to identify what is critical to quality (CTQ) to define the problem and to know what the scope is, since CTQ is what the customer really wants from the process.

The customer complaints for a company during a year illustrate the Voice of Customer (VOC) and it is given with counts in Table 1 (received for CEM I 42.5 R type of cement).

After gathering the voice of the customer (VOC), the critical to quality outputs (CTQs) which represent the performance and the characteristics of the process and the product (to satisfy customer expectations) are defined (Table 2).

Translating the VOC into critical to quality (CTQs) shows that variation of the final product’s quality leads to 68 % of the customer complaints. The defects are described as the variation in setting time and strength that cause customer dissatisfaction, reducing the company’s revenue and impairing its reputation.

3.2 Measure phase

During this phase, the focus is on gathering data to describe the current situation, so as to verify the impact once an improvement has been made. The three steps of CEM I 42.5 R type Portland cement production are focused so as to reduce the variance in the strength and setting time of final product. Table 3 gives the targets, lower and upper limits of parameters that are measurable for the three steps of the cement process. These targets are specified according to the plant quality manual and European Standard, EN 197-1:2012 (Composition, specifications and conformity criteria for common cements) [5].

Data are collected for given parameters of the three steps over half of 2016 (01.01.– 10.06.2016). For Step I and II, 486 relevant results are collected that consist of three results for each day since the cement plant is operated over three shifts in a day. Cement tests are done once a day so 162 daily results for the parameters of Step III are recorded. To minimize the risk to repeatability and reproducibility, the tests are conducted with the same instruments and by well-trained laboratory technicians according to EN standards.

For three sub-processes, defect items that result beyond the lower and upper limits are determined for the parameters. In this way, the current performance of the process is measured. The number of defects for each property and for the overall process are given in Table 4.

Table 5 shows the relationship between the sigma level and the metrics values where Eq. I, Eq. II and Eq. III are the formulas for DPU (defects per unit), percentage of yield and DPMO (defects per million opportunities). Sigma level is estimated according to the relationship given in Table 3.

3.3 Analyze phase

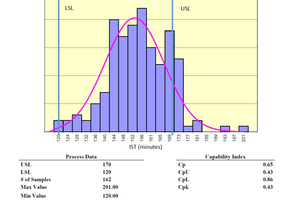

The problem is classified as a variation in the product quality that leads to customer dissatisfaction and threatens the market share in the Define phase. Early strength of cement and initial setting time of cement are the main causes of dissatisfaction. Histograms for the early strength and initial setting time of the CEM I 42.5 R type of cement with basic statistics are given below from 01.01.–10.06.2016 (Figure 3 and Figure 4).

The capability index (Cp) is an important indicator that is used in Six Sigma projects to denote the relation between the Voice of Customer (VOC) and Voice of Process (VOP). Briefly, VOC is defined as what the process or product must do and VOP is what the process or product can do. As the equations show, a Cp value larger than 1.0 means the process fits between the upper and lower specification limits and a Cpk value larger than 1.0 means the process is centered between the limits. Estimated capability equations are given below and Cpk is defined as the minimum of CpU or CpL.

⇥ Eq. IV

⇥ Eq. V

⇥Eq. VI

Upper and lower limits for the early strength of CEM I 42.5 R type of Portland cement are 26-30 MPa, which are specified according to EN 197-1 standard and plant quality manual. Only 119 of 162 products have passes for this interval, which means there are 43 defects. After both the number of defects and the correct items have been determined, capability indexes showing whether the process is capable or not are calculated. Since Cp < 1.0, the process is not capable. The graphical representation also shows the data distribution for 162 products and this histogram represents the variability and deviation from the center line of the target value in a bell shape. Defects or waste of the process that do not meet customer requirements can be seen which are outside the lower and upper limits.

Upper and lower limits for initial setting time of the CEM I 42.5 R type of Portland cement are 120-170 minutes, specified according to EN 197-1 standard and plant quality manual. 153 of 162 products have passes for this interval, which means there are nine defects. After both the number of defects and the correct items have been determined, the capability indexes showing whether the process is capable or not are calculated. Although the Cp value is larger than that obtained for two-days strength, it is again lower than 1.0 and the process is not capable.

3.4 Improve phase

In the analyze phase of this study, the root causes of the process problems are determined and potential root causes are identified. In the improve phase, possibilities are narrowed down for this project, the relationship between the suspected causes and the performance of the process is confirmed. According to the statistical analysis performed in the analyze phase, focusing on measurement, materials and methods was decided. To improve the performance of the process, corrective and / or preventive actions need to be implemented.

Raw meal quality stabilization is the starting point within the framework of the study. When the cement production process is divided into three steps, an improvement in mixing of raw materials leads to an improvement in raw meal, which has a positive influence on the clinker as the semi-product of the overall process.

The analyses of the raw meal are XRF analyses of manually taken samples. These samples are taken every two hours, and after the results of the samples have been analyzed, new feeding targets are input into the system. This method of process control obviously leads to late interference and low precision. For such a continuous process, online analysis and online control of raw materials from the conveyor belt lead to more consistent raw meal and clinker quality, and direct cost saving at the quarry and the plant. Online cross-belt analyzers have proven to be reliable and are widely applied in various minerals processing applications. Fast and early online analysis of the incoming raw materials upstream of the raw material grinding process helps to optimize the raw meal. There are different targets for quality modules such as the “Lime Saturation Factor” (LSF), “Silica Modulus” (SM) and “Alumina Modulus” (AM) at different plants. The main objective is to enable stable quality while saving on more expensive materials or maximizing the use of medium- or low-grade ores.

3.5 Control phase

The primary objective of the DMAIC control phase is to ensure that the gains obtained during the improve phase are maintained long after the project has ended. Adding an online analyzer to the system facilitates momentary control of raw materials. Analyzing the raw mix every minute and entering new setting minutes every five minutes enables a more stable process. Table 6 and Table 7 summarize the results from 01.07.–09.12.2016.

The results show that the sigma level increases from 2.7 to 4.0 for the first step of the production process, and from 2.6 to 4.0 for the second step of the process. An increase of the sigma level from 2.7 to 4.0 means an 18-times improvement and an increase from 2.6 to 4.0, a 21-times improvement. Finally, an increase of the sigma level from 2.7 to 3.6 results for the last step of cement production. According to the sigma methodology, an increase from 2.7 sigma level to 3.6 means a 6.3-times improvement of the process. (Defects per million decrease from 12 4691 to 19 753)

Yield percentage also shows the effect of improvement, with an increase from 88.68 % to 99.38 % for the 1st step and from 85.60 % to 99.33 % for the second step of production. For the last step of cement production, the yield increases from 87.53 % to 98.02 %, defects decreasing from 101 to 16.

4 Conclusion

The cement production process was improved in a continuous process using the DMAIC (Define, Measure, Analyze, Improve and Control) phases of the Lean Six Sigma methodology starting from customer complaints. The Voice of Customer (VOC) was translated to Critical to Qualities (CTQs), which were prioritized and evaluated in order to identify the root cause of customer dissatisfaction. Process capability indices were studied to compare inherent variability in the process with the specifications determined according to the customer requirements. Histograms and a fish bone diagram were used to visualize process performance. Two quality problems, unstable early strength of the cement and fluctuating early strength of the cement, were established. The raw material analyzing and controlling system was improved with the integration of an online cross-belt analyzer. With the online analyzer, the composition of the entire raw materials stream was measured at frequent intervals. Optimal set points were entered into the system in order to obtain consistent raw material quality with minimal chemistry deviation.

After the chosen solution had been applied, new data were collected and compared with the data collected during the measuring phase. The improvements were shown based on calculation of the process’s overall sigma levels for the three steps of the cement production process.

Although six sigma levels could not be achieved by only integrating an online analyzer in the system, an obvious improvement was made with achievement of 4σ in two steps of the process and 3.6σ for the last step of the process. As mentioned in fishbone diagram, more areas must be improved, such as environment, manpower and machinery. Furthermore, the objective of the lean six sigma methodology is not only to improve the process performance, but to enable the sustainability of the improved results in the long term.

//www.bolucimento.com.tr" target="_blank" >www.bolucimento.com.tr:www.bolucimento.com.tr

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.