Metal recovery and conversion of steel slag into highly reactive cement components

LOESCHE GmbHFor a long time a sustainable and careful use of our planet’s resources have been the motivation for industry and research institutions to improve the manufacturing processes of products continuously. One of these activities is to find a valorization for the iron and steelmaking slag in order to preserve natural resources.

1 Introduction

Germany produces approx. 6 million tonnes of steel slag (3.5 million tonnes of LD slag and 1.8 million tonnes of electric arc furnace slag) [1]. Depending on its lime...

1 Introduction

Germany produces approx. 6 million tonnes of steel slag (3.5 million tonnes of LD slag and 1.8 million tonnes of electric arc furnace slag) [1]. Depending on its lime content, this type of slag is used as road construction material or fertiliser. LD slag aggregates are used in particular for road construction as a non-bound base course but also as a bituminous-bound base course and top layer.

With regard to the preservation of resources and recent GHG-debates, worldwide there are already various activities to modify steel slag to a hydraulically highly-reactive material including recovering the metal content at the same time.

Over the past two years Loesche GmbH, Duesseldorf, has been considering the subject of ´refining´ steelwork slag to a highly-reactive cement component, whilst recovering the metal content at the same time as a focal point of its research efforts and works in close cooperation with the F.A. Finger-Institute of the Bauhaus University Weimar, Germany as well as the “Bundesanstalt für Materialforschung und -prüfung” (BAM) (Federal Institute for Materials Research and Testing), Department 4.4 “Thermochemische Reststoffbehandlung und Wertstoffrückgewinnung”.

2 Test results

Based on the origination process during the production of steel, LD slag contains quite a large amount of iron. While an insignificant portion is elementary bound metal, a much larger amount is based on oxide bonding. In this case, a physical separation process cannot be used to break up the oxide-bonded iron. Thermochemical processes in a reductive atmosphere lend themselves perfectly to this purpose. During this process, the iron which is initially bound in its mineral phases is converted into an elementary metallic form. This selective process of diminishing the iron concentration and other methods, places the composition of the melt, with respect to its material, in an optimum range for the formation of siliceous clinker phases (clinker standard in the range of 90 to 105). Thus, after a cooling period, a material similar to clinker occurs with a high reactivity.

During the method used by Loesche, the major proportion of metallic iron is concentrated during the melting process and discharged. The Fe-portion that remains in the new, clinker-like material will be separated in a downstream comminution process, using a Loesche mill that was specially designed for this application.

These tests were conducted at the BAM, Berlin-Adlershof, using a variety of steelworks slag in an electric arc furnace. The melted material charges each weighed between 200 and 300 kg.

The physical separation of the metal and the grinding of the modified cement slag took place in a small test facility at the Loesche Technical Centre. The chemical, mineralogical and construction material tests were conducted at the F.A. Finger Institute of the Bauhaus University in Weimar. Preparing the material for the grinding process, analysing the metal and evaluating the overall metal recovery was done by the Cala Aufbereitungstechnik GmbH & Co. KG in Aachen, Germany.

3 Results of the chemical and mineralogical analysis

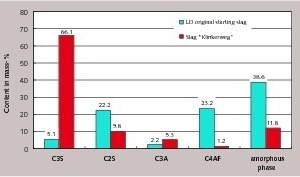

The four main clinker phases alite (C3S), belite (C2S), aluminate (C3A) and aluminate ferrite (C4AF) as well as X-ray amorphous phases (glassy phase) were detected as major mineral phases in the tested slag aggregate.

The untreated initial slag already showed a significant amount of belite (C2S) in excess of 20 %; and a glass content of 38.6 %. However, a corresponding reactivity was not present. The alite content of the initial sample was merely 5 M.-% (Fig. 1).

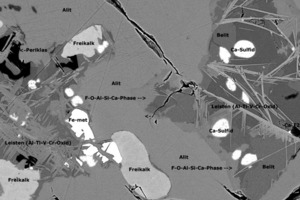

Comparing the initial slag aggregate, after clinkering the slag (so called “Klinkerweg”) a number of the present phases had changed significantly. Now, an alite content of approx. 66 % could be found. In order to ensure the results, they were reproducible and the tests were repeated several times. The results were consistent, producing similar alite contents in each case. Using a scanning electron microscope, the tests showed very compact areas of alites that were measurable within a range of several millimetres (Fig. 2).

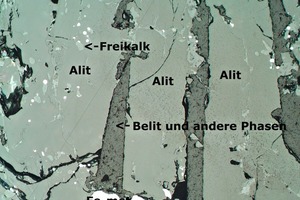

When etching the crystal surface, an attempt was made to make the grain boundaries (if existing) visible between the individual crystals and the large-surface alite areas in order to find an indication about the size of the alite crystals. After the tests in the electron microscope and after element mappings, the respective specimen was polished again in order to remove the carbon coating. Subsequently, the specimen was treated with a 0.5 % etching solution consisting of nitric acid in an alcohol solution in order to analyse the specimen in an optical microscope.

As Figure 3 shows, after applying the pickling solution for an extended time, additional grain boundaries within the alite areas are not detectable. Comparing these generated alite crystals with alites from conventional clinker production, the most significant results of the microscopic tests show the much larger size of the alite. Notably, despite a very slow cooling of the melt, a decay process to belite and free lime cannot be observed along the boundaries of the alite crystals.

4 Materials testing

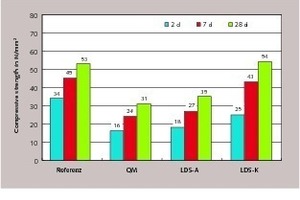

The following samples were tested:

100 % reference cement CEM I 42.5 R

70 % reference cement + 30 % silica sand (fraction 0/2 mm) as a non-reactive inert aggregate

70 % reference cement + 30 % clinkered slag from the melting tests

The results of the compression strength test are shown in Figure 4. It becomes clear that the new type of material derived from the Loesche process exhibits a high hydraulic potential. Already after two days, the slag itself supplies a considerable contribution to the strength development, thus indicating that this particular mixture exceeds the strength level of the comparison sample made of silica sand, so far. After seven days, the respective mixture nearly reached the strength level of the reference cement; in fact, 28 days later, the sample exceeded this level slightly.

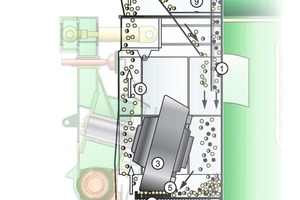

5 Grinding

Under the mechanical load applied by the grinding rollers during the comminution process, the mineral fraction is selectively crushed. The adhering mineral particles are, however, only superficially removed from the metal particles which retain their particle shape to the greatest possible extent. After successful crushing, the metal and mineral particles are discharged through the periphery of the grinding table into an upwardly-directed flow of gas. The lightweight mineral fraction is transported by the gas flow to the classifier, which is installed above the mill. Due to its higher specific density, the metal particles fall downwards against the gas flow and into the extraction feeder.

Particles of the mineral fraction to which some metal still adheres or which have not been ground to the required product fineness, will be rejected by the classifier rotor and, fall back due to gravity onto the grinding table for re-grinding.

It is quite feasible for the small amount of mineral fraction (< 10 %) which still adheres to the metal fraction to be discharged downwards. If the required purity is not achieved, further process steps, such as magnetic or density separation can be implemented downstream. The remaining mineral particles are fed back to the mill‘s circuit. When applying this operating principle of the Loesche mill, it is possible to separate almost 100 % of the metallic portion from the feed material.

Due to their modular design principle, Loesche mills can be equipped with 2, 3, 4 or 6 grinding rollers in order to meet the throughput demands of the operators.

6 Summary

After two days, a substantial strength development of the clinkered slag aggregate can be detected in the Portland composite cement, which comprises 70 % CEM I and 30 % modified alite-containing LD slag in the standard mortar. Comparing the strength development of ordinary Portland cement with composite cement containing modified slag its properties were almost identical after seven days.

In order to continue the comprehensive semi-industrial tests with a wider variety of steel slag aggregates, and to verify the technical feasibility and economics of the new procedure for industrial use, the research team led by Loesche will soon be joined by other industrial firms. A detailed report on further results related to this research will be provided shortly.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.