Influence of the granulation conditions and performance potential of granulated blastfurnace slag – Part 2: Chemistry and physical properties

Laboratory granulation is highly suitable as a means of demonstrating both the influence of different chemical compositions of granulated blastfurnace slag on its reactivity and the influence of different granulation conditions on the physical properties of granulated blastfurnace slag. The second part of this article deals with the chemistry.

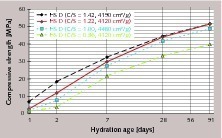

Fig. 13 also shows that laboratory granulation (HS D.0 and HS D.9) does not in itself change the reactivity of the granulated blastfurnace slag when compared with industrial granulation (HS D). This is an important requirement for the applicability of findings obtained in the laboratory to operational problems.

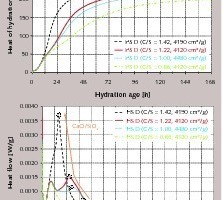

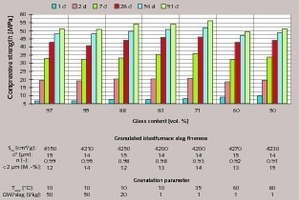

The granulated blastfurnace slags were to be ground to comparable finenesses. However, the fineness of granulated blastfurnace slag D with a basicity of 1.00 of 4480 cm2/g (d’ = 15 µm) was greater than the finenesses of the other granulated blastfurnace slags (4120–4190 cm2/g, d’ = 16-17 µm). This should be borne in mind when evaluating the reactivity, expressed as the heat of hydration or the strength development of blastfurnace cement, as not only the chemical composition but also the fineness of the granulated blastfurnace slag has a crucial effect on its reactivity. Fig. 14 shows the evolution of heat hydration from blastfurnace cements (slag/clinker = 75/25). It can be seen that the 2nd heat peak, attributed to the granulated blastfurnace slag, is displaced forward in times and is also changed significantly in intensity with rising basicity CaO/SiO2. The changed heat of hydration is also reflected in changed compressive strengths, as shown in Fig. 15. This means that, as expected, a higher basicity has a very positive effect on the reactivity of the granulated blastfurnace slag. The spread from 0.86 to 1.42 employed covers a wide range of the basicities found in industrial practice. According to the “Granulated Blastfurnace Slag File” at the FEhS Institute the granulated blastfurnace slag basicity (CaO/SiO2) averages 1.10 worldwide and the extreme values recorded so far range from 0.72 to 1.65. It is well known that blastfurnace slags with very high basicities form crystalline phases very readily and therefore under operational conditions cannot always achieve the very high glass contents normally found.

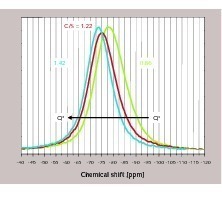

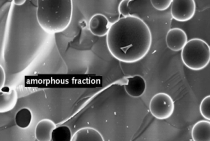

Investigations into granulated blastfurnace slag structure were carried out for some chemically altered granulated blastfurnace slags with high-resolution 27Al and 29Si nuclear magnetic resonance (NMR) spectroscopy in the cbm at Munich Technical University [6]. This method makes it possible to investigate the bond state and the surroundings of individual atoms. In silicates the degree of linkage Qn of the silicon tetrahedron can vary between Q0 for an orthosilicate to Q4 for a three-dimensional network. The chemical shift (relative distance of the sample resonance line from the resonance line of the chosen standard) decreases in 10 ppm steps from about –65 ppm for Q0 to about –110 ppm for Q4. It should be noted that it is not possible to compare the absolute heights of the peaks with one another as they depend partly on the duration of the measurement and partly on the absolute Si content of the sample. Peak positions and shapes are therefore only used for qualitative comparison. The greatest changes in glass structure at different CaO/SiO2 basicities were found for the granulated blastfurnace slags that had been granulated in the laboratory (Fig. 16). The higher the basicity the lower is the value of the chemical shift, which means that the degree of linkage decreases. This correlates with the model of the glass network that is often employed and the role of CaO as a network modifier as well as the well-known higher reactivity and greater corrodibility of granulated blastfurnace slags with higher basicities.

The positive effect of increased basicity on the granulated blastfurnace slag reactivity has in fact been known for a long time. However, the present results also make it possible to quantify these effects, initially for the “average” HS D granulated blastfurnace slag, as well as other effects that have already been known qualitatively. Other investigations into the influence of the chemical composition were carried out by varying the HS V granulated blastfurnace slag with a significantly lower initial basicity (C/S = 0.8) with the aid of the G3 granulation head geometry. After completion of the investigations these results will be reported elsewhere.

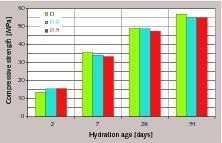

Laboratory granulations were carried out at the FEhS Institute for investigations, some of which are described in [11], in which the glass content of the HS Z granulated blastfurnace slag (C/S = 1.2) was varied between 50 vol. % and 97 vol. % by varying the granulation conditions at constant slag temperature (1600 °C). Fig. 17 shows that the blastfurnace cement (slag/clinker = 75/25) made with the granulated blastfurnace slag with the lowest glass content but with constant fineness had the highest 1-day compressive strength, although the other strengths either did not vary systematically (2, 7, 28 days) or else tended to decrease somewhat (56, 91 days) when the glass content was below the limit of 66 vol. % laid down in the standard. X-ray investigations confirm the formation of merwinite (C3MS2) in the crystalline fraction instead of the formation of melilite (C2AS-C2MS) that is usually observed with air-cooled blastfurnace slags. At constant chemical composition this results in enrichment of the aluminium in the glass phase [12], which leads to an increased 1-day strength. It should be noted that this was only achieved because the MgO content of the granulated blastfurnace slag had been raised from the original value of 7 mass % to 15 mass %. This means that the advantageous change in the glass chemistry can only become effective if the blastfurnace slag has a suitable chemical composition and a below-average glass content is obtained because of unfavourable granulation conditions, very low slag temperature or very high basicity.

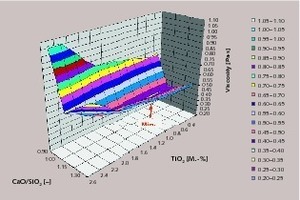

The viscosities of numerous re-melted granulated blastfurnace slags that were produced for the above-mentioned investigations were also calculated in relation to different temperatures and chemical compositions. A viscosity model that had been refined at the FEhS Institute and has proved successful in practice was used [14]. Fig. 18 shows how the viscosity of the liquid slag varies as a function of the CaO/SiO2 basicity and the TiO2 content for granulated blastfurnace slag D at a constant temperature of 1500 °C and a constant Al2O3 content of 11.5 mass %. It can be seen that a viscosity minimum is formed in the range of 0.35-0.40 Pa · s at a basicity of about 1.0 and a TiO2 content of about 0.4–0.8 mass %, which corresponds to a “natural” burden concentration. The aim of a blastfurnace operator is to adjust the charge composition to achieve minimum viscosity. This can naturally result in a conflict of interest if, for example, the higher basicity that is desirable from the cement technology aspect (cf. Fig. 15) leads to an unacceptable increase in viscosity of the liquid blastfurnace slag.

4 Summary

Acknowledgements

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.