Influence of the granulation conditions and performance potential of granulated blast-furnace slag – Part 1: Granulation conditions

Laboratory granulation is highly suitable as a means of demonstrating both the influence of different chemical compositions of granulated blastfurnace slags on their reactivity and the influence of different granulation conditions on the physical properties of granulated blastfurnace slag. The first part of this article deals with the granulation conditions.

1 Introduction

1 Introduction

Vitreous solidification is a precondition for the latent hydraulic behaviour of the granulated blast-furnace slag and therefore for its use as a main constituent of cement or as a reactive concrete addition. The engineering properties of granulated blastfurnace slag, including its dewatering and transport characteristics, its tendency to consolidation, its grindability and, naturally, its reactivity are determined by its physical and chemical properties. These depend on various parameters. It is well known that the level of the reactive potential of unground granulated blastfurnace slag is heavily dependent on the composition and glass content. However, the physical properties in particular can also be influenced by the granulation process. The nature of this influence is to some extent still disputed and is often only documented for specific individual cases.

So far there have been hardly any systematic investigations that use constant marginal conditions to demonstrate the complex influence of the granulation process on the properties of the granulated blastfurnace slag and could therefore show ways of optimizing the process (e.g. lower residual moisture). This was the incentive for extensive research work by the FEhS Institute that made use of the potential of laboratory granulation of re-melted blastfurnace slag or granulated blastfurnace slag.

2 Investigative programme

The FEhS Institute has various laboratory granulation units. Batches of about 2 kg of industrially produced air-cooled blastfurnace slag or granulated blastfurnace slag, possibly supplemented with correction materials, are fused in a graphite crucible in a Tammann furnace under an N2 atmosphere at 1400–1800 °C. When the slag appears homogeneous it is granulated in the shortest possible time (about 20 s) because of the imminent loss of temperature. As a rule the standard laboratory G1 granulation with 2-material nozzles is used to ensure the highest possible glass content (Fig. 1). The liquid slag is poured centrally through the granulation head, dispersed by water under pressure with a very high water/slag ratio, and passed into a water bath. The water temperature and water pressure, and therefore also the ratio of water to molten material, can be varied. A laboratory plant was also developed that resembles the granulation troughs (Fig. 3) that are still widely used in older industrial plants (Fig. 2). A more or less horizontal jet of water disperses the stream of slag and carries the particles into a water bath. The G3 trough granulation provides “softer” granulation conditions so that it is also possible to detect a purely chemical influence on the physical properties of the granulated blastfurnace slag (glass content, grain morphology) that experience shows is usually masked in the “sharper” granulation conditions with standard G1 laboratory granulation.

The laboratory granulation units are mobile so in the same way it is also possible to granulate liquid blastfurnace slag taken directly on site in the steel works during the tapping. It is particularly advantageous that in addition to producing granulated blastfurnace slag for scientific purposes it is also possible to check the engineering properties of a granulated blastfurnace slag (grindability, strength development, etc.) on a laboratory scale in relation to various practical parameters. This can be carried out before new expensive granulation plants (cost of a complete plant is about € 20 million) are built or before making changes to the industrial process, e.g. with respect to the burden composition, with their subsequent positive or negative effects for the cement producer.

3 Investigative results

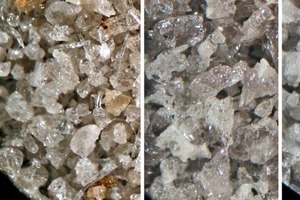

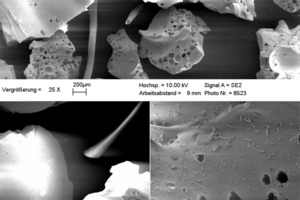

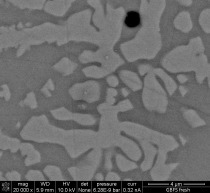

In order to examine these relationships systematically and exert a selective influence on the physical properties of the granulated blastfurnace slag the granulation conditions for the industrially produced HS D granulated blastfurnace slag were varied with different G1-G3 granulation head geometries at constant chemical composition (see Table 1 for characteristic data). The results for standard G1 laboratory granulation are summarized in Table 2. In some cases the HS D.0-D.9 granulated blastfurnace slags produced in the laboratory differed very sharply from one another. However, the glass content of the granulated blastfurnace slags determined by microscope was without exception 100 vol. %. Fig. 4 shows the HS D (Ptotal = 6.7 vol. %), HS D.0 (Ptotal = 5.8 vol. %) and HS D.9 (Ptotal = vol. 17.9 %) granulated blastfurnace slags under a reflected light microscope. The HS D and HS D.0 granulated blastfurnace slags were also examined under a scanning electron microscope for comparison (Fig. 5). A comparable angular grain shape and similar grain porosity can be seen in both cases.

As far as the influence of the granulation conditions on the physical properties is concerned it is clear that hotter blastfurnace slag normally leads to a more porous granulated blastfurnace slag as the degassing of the slag is apparently increased. Lower porosities can only be achieved in this situation if at the same time the water/slag ratio is relatively high, as with the HS D.3 granulated blastfurnace slag. In general, a higher water/slag ratio is beneficial with respect to lower porosity (cf. granulated blastfurnace slags HS D.0 and HS D.8). Under otherwise constant conditions higher granulation water temperatures lead to significantly more porous granulated blastfurnace slag (cf. granulated blastfurnace slags HS D.0 and HS D.9). This also holds true, but not to a significant extent, for the water bath temperature (cf. granulated blastfurnace slags HS D.2 and HS D.8).

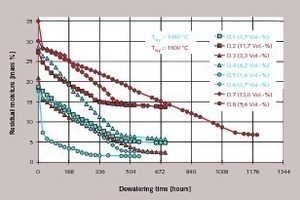

“Small silo” tests were carried out in order to characterize the dewatering characteristics of granulated blastfurnace slags with different porosities (Fig. 6). The dripping wet granulated blastfurnace slag that had been freshly produced with the G1-G3 granulation geometries was first stored for about 15 minutes on a 2 mm sieve to simulate preliminary dewatering, e.g. in a sieve drum. It was then stored on a 0.5-1.0 mm sieve in a vertical, open-bottomed, cylinder. This was intended to simulate silo dewatering. The granulated blastfurnace slag was then finally dewatered to constant weight at 20 °C and 65 % relative humidity.

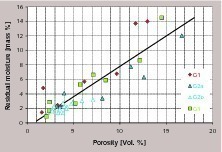

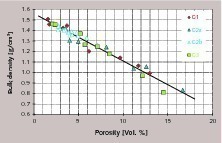

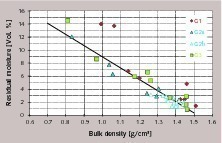

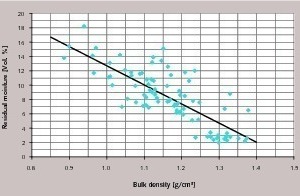

The change in residual moisture content is shown in Fig. 7. It can be seen that there are very wide variations both in the speed of dewatering and in the final residual moisture content. The latter correlates very well with the porosity of the granulated blastfurnace slag (Fig. 8), which under otherwise constant marginal conditions is in turn controlled by the granulation conditions. Laboratory granulation generates broadly similar grading curves so there is a correlation between bulk density and porosity (Fig. 9) and between residual moisture content and bulk density (Fig. 10). This result agrees with industrial experience, as is shown by Fig. 11 for granulated blastfurnace slags with differing origins. The greater degree of scatter of these measurements is a result of different transport times for the samples between taking the sample in the plant and analysis at the FEhS Institute.

The grindabilities of the granulated blastfurnace slags (the original particulate materials were tested) did not differ significantly in the Zeisel test. Relatively constant figures of 67-71 kWh/t were required for the granulated blastfurnace slags HS D.1-D.8 to obtain a specific surface area of 4000 cm2/g Blaine. This represents an average value for granulated blastfurnace slag in the Zeisel test. The different porosities definitely have a beneficial effect on the initial destruction of the coarse particle structure. However, the main energy requirement comes from grinding to cement fineness and depends on the glass content, and possibly also on the glass structure, but not on the porosity.

Table 2 shows that hotter slag, warmer granulation water and lower water/slag ratio produce a more porous granulated blastfurnace slag that is difficult to dewater and also contains more residual water. From this it is possible to derive guidelines for the design and operation of granulation plants. The slag temperature is determined to a great extent by the blastfurnace burden used and the attempts not only to use as little energy as possible but also, in spite of this, to obtain a sufficiently low slag viscosity. On the other hand, parameters such as granulation water temperature and water/slag ratio can be varied, at least to a limited extent, in existing plants and should be considered as controlled variables in new plants. A lower porosity of the granulated blastfurnace slag grain reduces operational problems and significantly lowers the unnecessary transport of water from the steel works to the cement plant and the amount of energy required for drying. This has a significant effect on the economic aspects of producing and using granulated blastfurnace slag.

The second part of this article will deal with the chemistry and physical properties of granulated blastfurnace slag.

4 Acknowledgements

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.