Hydraulic additive as a new “clinker substitute”

During the last four years, a hydraulic additive has been developed as a clinker substitute in the course of a research project at the Wopfinger Baustoffindustrie GmbH. The goals of the project were to provide the cement industry with an effective opportunity to reduce its CO2-emissions, to achieve economic advantages and to be able to produce the new product in existing cement plants.

1 Introduction

1 Introduction

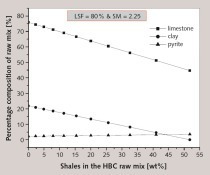

Sample calculations have shown a substitution rate of 25 % by mineral waste materials in the production of ordinary clinker while 46 % can be added to the new clinker substitute production. Due to the cheaper procurement costs of secondary raw materials, considerable financial advantages are achievable.

An additional saving cost effect arises in comparison to the production of Portland cement clinker when 1.65 t raw meal per ton of clinker is normally used instead of only about 1.21 t raw meal per ton of clinker for clinker substitute – this means 25-27 % less raw meal is required.

For over 40 years experiments have been done to bring the advantages of low CaO-content to practice. Several patents and publications (11/1971)[1] generally based on calcium sulfoaluminate cement confirm these efforts. Clinker of such a composition are characterised by a high content of melting-phase and a narrow range of melting temperature, which makes the burning process more difficult. The clinker shows high reactivity, fast setting and high early strength development. These properties make sulfoaluminate cements suitable for products with special requirements (e.g. fast setting repair mortar). Because of the high sensitivity such as for water metering and temperature fluctuations and especially to a precise dosage of required retarders, these cements are very difficult to control and, while processed, problematic or unsuitable for mass concrete.

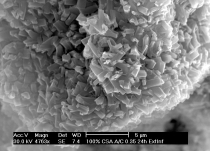

The clinker substitute developed with Wopfinger shows lower reactivity than sulfoaluminate cements. It consists mainly of mono-calcium silicate and mono- calcium aluminate phases, which show excellent long term strength development. However, due to the slow hardening the early strength development is slower. After performing numerous experimental burnings, it was possible to develop a product which shows a satisfying early strength development and which allows us to produce cements with extraordinary quality properties for a broad spectrum of applications. The production method and the product itself are patented.

2 Compressive strength development

in comparison with common cements

Despite a higher dosage of clinker substitute, higher early strengths could be achieved than in cements with common additives (Tab. 2). Thus, the following positive characteristics in the cement with clinker substitute can be summarized:

High early strength development reduces the risk of drying out and the required finishing is influenced positively.

Sustainability and durability of concrete structures are increased especially by the use of cement with clinker substitute. On the one hand they cause a strong post curing by a low lime saturation resulting from mono-calcium silicates and mono-calcium aluminates, while on the other hand a better grindability and fineness of clinker substitute is observed, whilst a high packing density and a dense structure of concrete resulting an impermeable dense concrete for a long life.

Less heat generation in the formation of the hydrate phases reduces the risk of crack formation.

Increased sulfate resistance in consequence of the reduced amount of tri-calcium aluminate.

Additional researches confirmed resistance against freeze-thaw and de-icing salt on concrete made of clinker substitute.

Another advantage of the clinker substitute production is that there is 50-60 % less carbon dioxide emission than with a conventional Portland cement clinker process. These total CO2 emissions are greatly reduced on the one hand - process related - by less de-carbonization of the raw meal mixture and on the other hand - combustion related - by less fuel consumption for burning.

Particularly favourable is to reduce the flame temperature lower than usual, consequently less fuel is needed and the thermal kiln load can be reduced. Usually, ordinary Portland cement clinker is burnt at 1380 °C while the presented clinker substitution can be burned at about 1200°C.

In addition the burnt clinker shows a good grindability, which is correlated to less energy demand.

Is is also important to mention that clinker substitution can be produced in conventional cement works where no large investments are necessary.

The trial ran without any interference regarding the lower thermal kiln load and without any kiln coating. Despite the 9 % higher performance, the consumption of natural gas could be reduced by 50 %. This results in a total energy saving over 50 %. The reduction of CO2 emissions was 57 %. This burnt clinker substitute shows a consistent quality and a much better grindability than ordinary Portland cement clinker.

It is well known that the performance of rotary kilns is defined by the highest possible input of thermal heat. Reduced energy consumption for the production of clinker substitution allows an essential increase of the performance of the rotary kiln compared to traditional processing of Portland cement clinker. If the general conditions, for example the capacity of the raw meal or clinker transport or the rotational speed, have to be adapted to a larger kiln output, this can be done with an appropriate small investment. The combustion proceeded without disturbances due to the lower thermal stress in the kiln and without increasing of the coating.

3 Summary

Economically, much lower raw material costs and significantly reduced energy consumption as well as an improved kiln performance are observed, resulting in an easier grinding of the clinker.

Product-specifically this cement allows a wide range of applications with a clear improvement in sustainability and a uniform product quality by controlling the raw material mix and of the burning process with the clinker substitute. In addition, the clinker substitute can be burnt in existing production facilities and has a special significance for countries where no additives are available or where additives are scarce or too expensive.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.