How safe is your silo?

How long does a silo last, and what can we do to lengthen its life span? One way to do so is to ensure timely inspections and good maintenance. How? This contribution provides some answers.

1 Introduction

Every building comes with a certain service lifetime. If not properly managed, that time will eventually run out, and your structure will ultimately collapse. Statistically speaking, silo structures collapse three times as often as bridges and other civil structures all over the world. Even structures as sophisticated as soccer/football stadiums, bridges and skyscrapers are safer than silos.

There are two main reasons for this:

1. While the live load of a silo amounts to approx. 90 % of its total load, the live load of a bridge or similar structure amounts to less than 50 % of its...

1 Introduction

Every building comes with a certain service lifetime. If not properly managed, that time will eventually run out, and your structure will ultimately collapse. Statistically speaking, silo structures collapse three times as often as bridges and other civil structures all over the world. Even structures as sophisticated as soccer/football stadiums, bridges and skyscrapers are safer than silos.

There are two main reasons for this:

1. While the live load of a silo amounts to approx. 90 % of its total load, the live load of a bridge or similar structure amounts to less than 50 % of its total load. In other words, silo structures are used much closer to their service limits than other buildings

2. Maintenance also differs. Buildings & bridges are used by people, and those same people often detect cracks and corrosion at an early stage. Many public and private buildings are also monitored by facility managers responsible for taking care of them.

But who takes care of a cement plant silo? No one, actually, and as long as all the equipment is running smoothly, everything is considered to be alright.

2 Definition of service lifetime

The service lifetime is the period of time in which the rebars and post tensioners are able to hold back the bulk material inside a silo.

Poor quality concrete, design errors and corrosion can curtail a silo’s service lifetime.

Only if the overlap rebarring is covered with a proper layer of concrete will it be able to transmit the tensile forces from one rebar to the next. The employed concrete cover is important not only for purposes of force transmission, but also for protecting the rebars from acidic environmental influences.

One factor of importance for calculating the remaining service lifetime is the depth of carbonation in the concrete cover. The term carbonation describes the zone of concrete, beginning at the surface, that has changed from naturally basic to acidic. Air pollution, saltwater and acid rain all accelerate this process.

If the carbonation zone extends all the way in to the steel rebars, they will begin to corrode and lose their Fe content.

3 How much service lifetime does

your silo still have?

Answering this question requires a structural inspection. A sky worker has to examine the quality of the silo’s outer concrete surface, look for rebar corrosion, check the carbonation depth and measure the concrete cover (Figure 2 a-c). Also, the inside surface must be checked for abrasion.

The design analysis pinpoints the structure’s safety factor (without consideration of quality deviation and erection errors).

The composite results of this investigation enable calculation and estimation of the silo’s remaining service lifetime.

4 What kind of repair is required?

If the owner is not satisfied with the calculated remaining service lifetime, the structure will have to be reinforced.

The adopted repair concept must be based on the results of the design analysis, the remaining concrete cover and the carbonation depth.

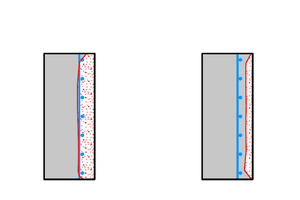

Figure 3 shows that, if the carbonation layer extends beyond the concrete cover (at left), a repair solution would be too expensive, and the silo will have to be replaced. If, however the carbonation layer is still confined to within the concrete cover (at right), a soft or heavy solution can be achieved.

If the concrete has suffered only local damage, a local repair approach with modified mortar products (soft repair) may be sufficient. The trouble with modified mortar products, however, is that they only work to a maximum thickness of some 20 – 40 mm. Thicker layers are prone to shrinkage-induced cracking, even if “non-shrinking” mortar is used.

If large areas of damaged concrete need repair, a mortar-based solution would be both too expensive and technically inappropriate. The mortar would develop craquelure-like fissures, and water will again be able to penetrate unobstructed to the reinforcement. In order to achieve another 15 to 25 years of useful service, such a solution must be topped with a crack-bridging coating. In such cases, it would be much cheaper to apply an additional layer of concrete, i.e., self-compacting concrete (SCC), as a heavy repair option.

If the results of design analysis are unsatisfactory, the rebarring will have to be reinforced with or without a concrete repair solution.

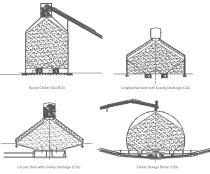

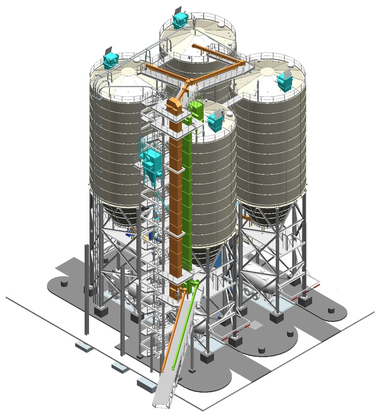

5 If a new silo is required, then what kind?

First of all, in order to work out an economical storage solution, the type of stored material and the live capacity must be given. The local preconditions at the plant are also very important for the design. The main factors to consider in the search for the most economical storage solution are the local soil conditions (bearing capacity and settlement modulus), the available space and any settlement-sensitive buildings or equipment located nearby.

These local variables are the reason why there is no typical, universally applicable, economical set of dimensions for silos of different size in different places. In other words, every single storage unit or silo requires adaptation to the prevailing local, on-site conditions. By definition, then, silos and storage buildings are custom-built products.

Factors that tend to inflate the cost of construction include a lack of available space for the building, adverse soil conditions and any settlement-sensitive buildings that may be situated nearby.

Confined available space on site means that the entire load of stored material plus the weight of the building itself will have to rest on a small piece of ground, hence subjecting it to high specific ground pressure.

Piling is usually required for transferring the load from the soil surface to deeper soil formations with higher bearing capacities. Unsuitable soil conditions marked by low load-bearing capacity also call for piling, because piling can substantially reduce the degree of soil settlement under silos and storage buildings. Of course, if piling is required for a silo or storage building, the cost of construction will by higher by some 25 to 35 %.

After the first few years, the settlement curve underneath a silo or storage building begins to shift. This should not be allowed to cause damage to other buildings or equipment (whereas the columns supporting belt conveyor bridges are the most susceptible to this effect). If settling threatens to become excessive, (additional) piling will be required.

Silos supported by piling or rock can be given smaller diameters and higher side walls. The diameter and height of a silo have direct effects on the horizontal loads exerted by bulk material. The higher the side walls, the lower the horizontal bulk pressure (silo effect). Silos and storage facilities with side wall heights exceeding a certain proportion require prestressing. Prestressed concrete structures have many advantages, but their cost of construction is some 25 to 35 % higher, especially in low currency countries.

Choosing the right kind of formwork for a silo or storage structure is another potential cost-saving factor. While slip formwork offers the best performance, climb formwork is a good, less expensive alternative that enables construction of large non-prestressed silos.

6 Proportionality and reasonableness

Similar to the assessment of earthquake rehabilitation measures, the costs and benefits of available alternatives are compared for silo buildings and then written off over the remaining useful lifetime (Table 1).

7 Conclusion

Someday, your silo’s service lifetime will come to an end, but you can surely cope with that! A professional silo-condition investigation will only cost you a small amount, and once you know how much useful life your silo still has, you can plan your investment (capex) and show the owner, your staff and the public authorities that you are handling your plant with care.

The typical silo structure has a service lifetime of approx. 50 to 75 years, depending on its quality of construction, design reserves and environmental influences.

In economic terms, this service lifetime translates to annual costs of 1.5 to 2 %. If you decide to invest in your old silo structure, the cost of repair divided by the remaining service lifetime should therefore be lower than 1.5 to 2 % of what a new silo would cost. Otherwise, a repair solution would not be a smart investment.

//www.wuerthconsulting.com" target="_blank" >www.wuerthconsulting.com:www.wuerthconsulting.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.