Green hydrogen utilization in lime kilns – Greenhouse gas savings and implications on the energy system

Due to climate targets and rising CO2 prices, the cement industry is obliged to reduce greenhouse gas (GHG) emissions. The utilization of green hydrogen in lime kilns is discussed as a promising way to reduce fossil fuels use and cut GHG emissions. This article gives some insight into the possible GHG reduction by utilizing green hydrogen and further discusses the results in a national perspective.

1 Introduction

Cutting greenhouse gas (GHG) emissions is a constant struggle that all sectors and industries are facing nowadays. Many GHG abatement technologies are discussed for the application in the cement industry. Increasing the energy efficiency of the production facility must be the first part of cutting and avoiding GHG emissions. Nevertheless, there is a technical limit for the minimum energy consumption of processes. In order to reach a deep decarbonization of the processes the industry can on the one hand avoid greenhouse gas emissions or, on the other hand, use end of pipe...

1 Introduction

Cutting greenhouse gas (GHG) emissions is a constant struggle that all sectors and industries are facing nowadays. Many GHG abatement technologies are discussed for the application in the cement industry. Increasing the energy efficiency of the production facility must be the first part of cutting and avoiding GHG emissions. Nevertheless, there is a technical limit for the minimum energy consumption of processes. In order to reach a deep decarbonization of the processes the industry can on the one hand avoid greenhouse gas emissions or, on the other hand, use end of pipe technologies to capture the released greenhouse gases (Carbon Capture and Storage/Utilization). In addition to energy efficiency measures, greenhouse gases can be avoided by integrating renewable energy sources, namely renewable electricity, into the process to substitute fossil fuels. One very prominent and in politics present approach to electrify technical processes is the utilization of green hydrogen.

The hydrogen can be supplied by electricity driven water electrolysis. This article clarifies the notion “green hydrogen” in terms of the cement industry. The notion is often used to describe the environmental friendliness or low GHG emissions of hydrogen. The electrolysis is fed with electricity from renewable sources. But how green is sufficiently green for the cement industry to cut GHG emissions of a lime kiln?

This article will introduce some information about the assumptions and scope of the calculations. Afterwards the marginal emission factors for substituting three fossil fuels by green hydrogen are presented. Furthermore, the yearly GHG savings for a cement kiln that replaces fossil fuels with hydrogen produced from different types of electricity are discussed. In the third section, the article draws a picture of a German cement industry that would replace fossil fuels by hydrogen produced via electrolysis.

2 Background: Current state and greenhouse

gas balancing

An energetic substitution of fossil fuels by hydrogen is assumed. It means that one energy unit of fossil fuel is substituted by one energy unit of hydrogen. The firing technology is not topic of the article. We assume no changes in the process like energy efficiency losses caused by the substitution of fossil fuels by hydrogen.

2.1 Fuels used in the cement industry

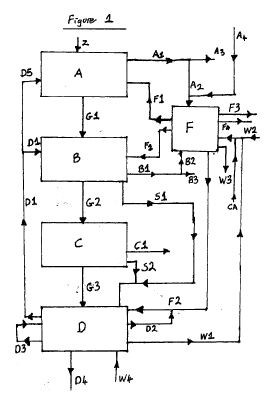

Figure 1 illustrates the fuel used in the German cement industry in 2019. A major part belongs to alternative fuels that have already replaced fossil fuels. The most important fossil fuels still in use are hard coal and lignite.

2.2 Green hydrogen production

Hydrogen can be produced by various technologies. In this article, water electrolysis produces hydrogen, which will then be combusted in the lime kiln. In addition to hydrogen, the process also generates oxygen. During electrolysis, water is split in an electrochemical cell according to the following equation:

2 H2O → 2 H2 + O2

In order to assess the required capacity of the water electrolysis, a partial-load and a full-load scenario were assessed. The first scenario uses 2000 full load hours, as it is applicable to represent a supply by wind power only. The second scenario assumes 8000 full load hours, which is a pursued amount of full load hours for economic reasons. The efficiency of the water electrolysis is assumed to be 70 % based on the lower heating value of hydrogen. All emissions from the used electricity are allocated to hydrogen as it is the main product of interest.

2.3 Greenhouse gas balancing

GHG emissions in the cement industry can be divided into direct and indirect emissions. Direct emissions are released onsite and originate predominantly from carbonaceous fuel combustion and the decarbonization of limestone. The major indirect emission source is the use of electricity.

Furthermore, the emissions are grouped as process or energy-related emissions. The GHG emissions from the decarbonization of limestone are process-related emissions that originate directly from the process itself. Energy-related emissions occur due to the utilization of energy for processes.

The system boundary for the calculation is set to be the site of the cement kiln or for the national perspective the cement industry. For the calculation of relevant GHG emissions, scope 1 and 2 emissions were considered. Emissions from scope 1 arise directly within the system boundaries (e.g. emissions from decarbonization of limestone or the combustion of fuels onsite). Scope 2 emissions take the indirect emissions of energy that crosses the system boundary into account (e.g. electricity supply). The calculations of emissions are based on the emission factors in Table 1.

2.4 Marginal emission factors

For the production of hydrogen via electrolysis, the emission factor of the electricity plays an important role for the emissions allocated to hydrogen. The marginal emission factors for electricity are calculated based on the energetic substitution of a fossil fuel by hydrogen taking into account the efficiency of the electrolysis. The marginal emission factor states the electricity’s emission factor used for the electrolysis in order to exactly cause the same GHG emissions as the fossil fuel to which it is compared. An emission factor of the electricity used for hydrogen production below the marginal emission factor means a net GHG saving.

3 Results and discussion

3.1 Calculations for the substitution of fossil fuels

The following calculations focus on the substitution of fossil fuels by hydrogen. First, marginal emission factors are calculated for the substitution of three fossil fuels. Afterwards the yearly change of GHG emissions per MW of thermal energy are presented.

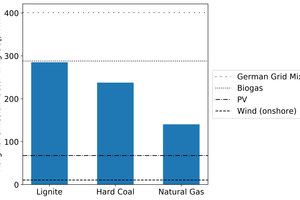

3.1.1 Marginal emission factors for electricity

The marginal emission factors for the utilized electricity when substituting the three fossil fuels hard coal, lignite and natural gas in lime kilns is shown in Figure 2. As an example, the four horizontal lines indicate the emission factors of electricity from wind, photovoltaics (PV), biogas combustion and electricity from the German grid. The marginal emission factors for lignite and hard coal are conspicuously higher than the one of natural gas. This fact is ascribed to higher emissions of coal combustion that leads to higher acceptable GHG emissions for the used electricity.

A substitution of the three fossil fuels by hydrogen produced with electricity from the German grid mix causes considerably higher GHG emissions. Thus, using the recent German grid mix is not applicable for lower energy-related GHG emissions. This shows that a decarbonization of the German grid mix has to occur before considering the grid mix as a viable source for green hydrogen production. The utilization of electricity from wind and photovoltaics shows for all fossil fuels significant GHG savings. The electricity from biogas is for all three cases not a competitive option for GHG reduction.

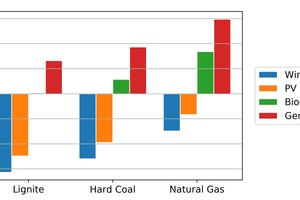

3.1.2 Change in annual GHG emissions

For the four sources of electricity, Figure 3 shows the change in GHG emissions per MW of thermal power if the respective fossil fuels are substituted by hydrogen. The results assume 8000 full load hours of the kiln and report the annual emission change possible. The emissions are calculated based on the difference of the emission factor of hydrogen and the emission factor of the respective fossil fuel. Negative values represent GHG savings.

Substituting natural gas shows the lowest potential for cutting GHG emissions as natural gas is an energy carrier with low GHG emissions compared to solid fossil fuels (see Table 1). For all three fossil fuels, the utilization of the German electricity mix for hydrogen production would lead to significantly higher emissions. In general, hydrogen produced from renewable energies like wind or PV can reduce GHG emissions. For the substitution of lignite and hard coal, the GHG emission can be tremendously decreased by using electricity from wind or PV compared to substituting natural gas. Due to the higher GHG of lignite compared to hard coal, the substitution of lignite is more effective in cutting GHG emissions. For electricity from biogas combustion, the GHG emissions would increase for all three fuels.

As an example, the substitution of 1 MW of lignite in a lime kiln by hydrogen is illustrated. The combustion of lignite emits 3257 t CO2 per year. Hydrogen produced from the German grid mix would increase the emissions by 41 % to 4583 t CO2. On the other hand, a cut of 96 % (122 t CO2) in GHG emissions is possible, if wind power is used for hydrogen production.

3.2 National perspective on the German

cement industry

The maximum utilization potential for hydrogen as a fuel is evaluated for the German cement industry by substitution of fossil fuels through hydrogen. Values are reported on an annual basis. The consumed fossil fuels accounted in 2019 for 8.3 TWh in total [1]. An additional 18.4 TWh were supplied by alternative fuels [1]. The electricity demand was 3.9 TWh [1]. The goal is to substitute the fossil fuels by hydrogen. The alternative fuels will probably not be replaced because of their availability. According to a yet withdrawn patent, a supply of 50 % of the thermal energy required in the lime kiln by hydrogen is feasible [5]. Since fossil fuels account for less than 50 % of the total energy used, all fossil fuels can, in a national balance, be replaced by hydrogen.

The changes for the energy balance of the German cement industry are shown in Figure 4. A substitution of fossil fuels by hydrogen leads to an electricity consumption of the water electrolysis of 11.8 TWh. In comparison, the annual electricity demand in Germany amounts to 513 TWh (2018) [6]. In this case the electricity consumption for electrolysis would cause an increase of the national electricity demand by 2.3 %. This shows the significant influence on the German energy balance through the electrification of the production process. In terms of the total electricity demand of the German industry (227 TWh) the electricity required for hydrogen production in the cement industry would result in an increase by 5.2 % [6]. Furthermore, an increase of the electric energy demand of 11.8 TWh occurs. When considering the energy input depicted in Figure 4, the substitution of the fossil fuels leads to an increase in energy intensity of the cement industry since more energy in the form of electricity is required. The electricity demand of the electrolysis causes a higher total energy demand of the cement industry and thus lowers the energy efficiency of the industry’s energy supply.

The full load hours of the electrolysis influence the power of the electrolysis unit. A calculation with different full load hours of the electrolysis unit shows the size of the electrolysis unit supplying the required amount of hydrogen. Scenario 1 and 2 would require an electrolysis unit of 1.5 GW and 5.9 GW capacity, respectively. The current load in the German electricity grid is in the mid two-digit GW range. Consequently, an electrolysis unit significantly increases the load leading to a higher requirement for the capacity of the electricity net.

In order to actually reduce GHG emissions, the emissions of the utilized electricity are of great importance. These emissions lead, with the previously presented electricity consumption of the water electrolysis, to an industry-wide marginal emission factor for the electricity of 238 kg CO2/MWh. In order to cut GHG emissions, the emission factor of the utilized electricity has to be below the value. Utilization of the German grid mix would again increase the GHG emissions for the cement industry. Indeed, not all renewable energy sources are beneficial for the reduction of greenhouse gases. The emission factor of electricity from wind and PV are given in Table 1. These types of electricity could reduce the GHG emissions of the industry. Furthermore, there is a shift to higher indirect emissions due to a higher electricity demand. Additionally, the share of process-related emissions will increase.

4 Conclusion

The utilization of hydrogen in lime kilns is a hotly discussed topic. This article provides some insight into the GHG balancing for the utilization of hydrogen and implications from a national perspective. It is obvious that hydrogen production via electrolysis shows some major implications for the carbon intensity of the used electricity. Not all kinds of renewable electricity can provide GHG savings for the substitution of fossil fuels. The current German grid mix is not able to cut GHG emissions no matter what fossil fuel is substituted. Depending on the fossil fuel that is substituted, electricity from wind power and photovoltaics has a good potential to save GHG emissions.

From the perspective of the German cement industry, the maximum potential for hydrogen utilization has huge impacts on the national electricity consumption and would tremendously increase the grid load. Consequently, the electricity grid has to be extended to take up the increased load. Furthermore, the marginal emission factor for the industry has to be below 238 kg CO2/MWh that can be met by electricity from wind power or PV for example. Furthermore, the implementation of hydrogen utilization increases the total energy demand of the industry. Consequently, the energy intensity increases.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![1 Fuel used in the German cement industry in 2019 (green: alternative fuels, red: fossil fuels)[1]](https://www.zkg-online.info/imgs/1/6/1/6/6/8/1/tok_b0cca04a82f98d1b28c7df8d4d983e69/w300_h200_x600_y306_Figure1_UsedFuels-1ed7bb0a041c3212.jpeg)

![4 Sankey diagram for the energy flows of the German cement industry (based on own calculations and [1]) (a) Status Quo (2019), (b) Substitution of fossil fuels by hydrogen (hatched arrow represents the electrolysis process)](https://www.zkg-online.info/imgs/1/6/1/6/6/8/1/tok_b2e2815a9bc6f3dfff4801353e929864/w300_h200_x600_y189_Figure4_Sankey-83f71ec6aa40d40a.jpeg)