Efficient injection of secondary fuels

Secondary fuels are being used with increasing frequency in the cement industry. However, the fact that they have significantly different properties from other bulk materials is often ignored, which means that many plant operators are still looking for efficient and reliable injection systems. Injector conveyors, blower shoes and blow-through feeders of every type are used for transferring secondary fuels into pneumatic conveying plants. However, practical experience has shown that individually these systems are of only limited suitability for secondary fuels.

The obvious course was therefore...

Secondary fuels are being used with increasing frequency in the cement industry. However, the fact that they have significantly different properties from other bulk materials is often ignored, which means that many plant operators are still looking for efficient and reliable injection systems. Injector conveyors, blower shoes and blow-through feeders of every type are used for transferring secondary fuels into pneumatic conveying plants. However, practical experience has shown that individually these systems are of only limited suitability for secondary fuels.

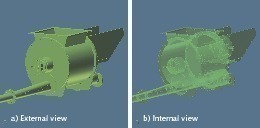

The obvious course was therefore to consider further development. Di Matteo Förderanlagen GmbH & Co. KG set itself the target of developing a new injection solution. The technical solution to the problem has been constantly refined on the basis of the practical experience that had been gained, so there is now a 3rd generation of feeders. The ODM IZS® injector rotary feeder (Fig. 1) links the rotary feeder technology refined at DI MATTEO with the requirement that often occurs of feeding difficult bulk materials, such as secondary fuels, sewage sludge, bypass dust or slaked lime, reliably into pneumatic conveying systems. It combines a modified rotary feeder with an injector to ensure efficient inward transfer of secondary fuels and other bulk materials. The injector is an integral part of the rotary feeder. A protective right has been granted for the ODM injector rotary feeder [1] .

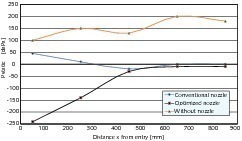

The leakage air can be minimized and the conveying air can be practically entirely utilized for the pneumatic conveying by carefully controlled injection of the conveying air at high speed through the injector parallel to the axis of the cellular rotor. The behaviour of this combination had been investigated beforehand in laboratory trials with models and the industrial IZS® injector rotary feeder. Some examples of the test results are shown in Figure 2. In this diagram the static pressure Pstatic is shown as a function of the distance x from the entry of the conveying air into a chamber of the rotary feeder. It can be seen from this diagram that with the “traditional” blow-through rotary feeder, i. e. a feeder without any nozzle, there is always a positive static pressure that causes the great “air leakage rate” of the rotary feeder.

A negative static pressure that in practice almost completely suppresses the “air leakage rate” was established at the wall over the entire length of the cell by optimizing the air inlet nozzle. This can prevent problems with the inward transfer of light-weight secondary fuels. When these enter the cellular rotor they are often forced back in the direction of the feed shaft by the leakage air. This can cause blockages and segregation of the material. The internal pressure of the system opposing the entry of material into the feeder varies depending on the quantity being conveyed and distance covered. This is not the case with the new principle. The negative static pressure eliminates any blow-back of the material being conveyed. This approach has proved successful in industrial applications. Depending on the overall plant design the negative pressure means that the material inlet shaft of the new injector rotary feeder can be opened during operation without any of the material escaping.

The Di Matteo developers have undertaken some adaptations to the cellular rotor for the new development. The combination of a hard seal, of the type also preferred for a knife feeder, and a soft seal against the housing makes a significant improvement in the seal of the cellular rotor against the housing and at the same time provides high wear resistance. The hard seal can be adjusted accurately and set to a given gap between the knife blade and the housing. A minimum gap of 0.4 mm is recommended in the literature [2]. The resulting loss of air-tightness is offset by a downstream soft seal. The new type of seal structure means that it is also possible, depending on the requirements or the client’s wishes, to incorporate either just a soft seal or just a hard seal, in which case the feeder would function as a knife rotary feeder. A protective right has been granted for the newly developed radial seal.

Service lives of up to a year can be achieved with the new seal during the standard use of secondary fuels. If necessary, the inner housing and the end covers can also be made wear-resistant. The latest development is an injector nozzle that can be adjusted during operation. This adjustability means that the unit can be set to suit the mode of operation of the plant, which makes it easy to compensate for larger quantities of feed.

The new development provides conveying rates of 20 t/h or more, depending on the material and the other conditions, and is suitable for all areas in which secondary fuels (fluff, animal meal, etc.) as well as conventional bulk materials have to be introduced into pneumatic delivery lines.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.