Cement manufacturing is an energy-intensive process. In addition to the high consumption of fuel for calcination and clinkering, which requires temperatures in the range of 1400 °C to 1450 °C, electric energy is needed to process the raw materials, cool the clinker, and grind the cement. The use of advanced technology such as rotary kilns and pre-heater has optimized the calcination process to a point where no further significant reduction of energy consumption through procedural measures is expected.1

1 Enhancing energy efficiency

For years, other strategies have also been pursued in the cement industry to improve energy efficiency and reduce the carbon footprint. One approach is to replace the primary fuels, mainly hard coal, with refuse-derived fuels such as car tires, meat and bone meal, animal fats, preprocessed sewage sludge, or pretreated materials from industrial and commercial waste. The biggest challenge is posed by the different fuel properties such as moisture content, reactivity, and calorific value. They influence the flame and the temperature profile of the rotary kiln and require continuous adjustment of the burner to achieve constant product quality and low pollutant emission with different fuel inputs. To achieve this, a modern burner control system is necessary.

Another option to improve energy balance and reduce the carbon footprint is the production of cement with a lower content of clinker since its calcination, in particular, consumes a large amount of energy. These raw material substitutes are industrial by-products such as slag and fly ashes. Although the energy balance of these substitutes is better, they cannot be added in any significant amount as this would greatly impair the quality of the cement. Hence, intelligent measuring methods and professional field devices are essential for apportioning these substitutes and the subsequent homogenization processes.

In recent years, research has focused increasingly on the use of alternative binding agents with lower requirements of lime and energy. In addition to so-called belite cements, geopolymers, and sulphoaluminate cements, also Celitement should be mentioned here, which is based on hitherto unknown calcium-hydrosilicates. The future will show which approaches will lead to sustained improvement of the energy balance and the carbon footprint of cement.

2 Success factor: process stability

Aside from capital-intensive measures such as the installation of heat recovery systems and new motors, the use of refuse-derived alternative fuels, or the development of new binding agents, one aspect that should not be forgotten when we consider energy optimization is the need to maintain a stable and trouble-free production process. To enable cement works to produce cement around the clock, all sub-processes – from crushing of the limestone, to burning of the clinker, to storing of the finished cement in silos – need to function flawlessly and interact perfectly. Up-to-date control systems tailored to the requirements of the cement industry – such as CEMAT, which is based on the Siemens process control system SIMATIC PCS 7 – ensure achieving and maintaining those perfect conditions. They enable optimal use of thermal and electrical energy. However, the procedure requires good field data, which needs to be acquired through appropriate measuring procedures. Choosing the ideal measuring method has a decisive influence on the efficiency of the overall process and requires industry-specific expertise and extensive knowledge of the physical-technological challenges. The examples given below show how the combination of measuring methods and appropriate field devices can make cement manufacturing more efficient.

3 Level measurement at the crusher

The crushers play the most important role during the preparation of raw materials. They crush the limestone, which is the main component of all types of cement. As they are one of the biggest energy consumers, it is important to ensure an optimal workflow. Although there are different types of construction for crushers, based on an ideal filling level they all have in common that they work most efficiently when the stones break each other. If the level is low, the stones are not crushed to the desired size and must pass through the crusher again. This results in doubling the energy consumption – already at this point. At the same time, the mechanical parts of the crusher are stressed more than necessary and the plates or rollers exhibit more wear. On the other hand, if the filling level is too high, feeding must be interrupted and the process comes to a halt. Continuous measurement is essential to keep the crusher at the optimal filling level. This is a challenge under the prevailing conditions. Due to the dust, extreme vibration, and stone debris flying around, measuring equipment with sensitive electronics cannot be used inside. Where radar and laser applications fail, ultrasonic level instruments such as the Siemens Echomax ultrasonic sensors are optimal. They are hermetically sealed, extremely compact, and emit their acoustic pulses in a narrow beam. Suitable for operation in the crusher are the Echomax XLS transducers that work together with SITRANS LU controllers such as the SITRANS LUT400. The fill-level transducer precisely measures the time between transmission of a pulse and the receipt of the echo, and calculates the distance between the sensor and the limestone within seconds. Fill-level monitoring ensures optimal feeding of the crushers and energy-efficient crushing of the limestone.

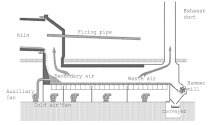

4 Gas analysis in the kiln

The rotary kiln is the core piece of clinker production and the biggest consumer of thermal energy. Continuous, reliable, and precise analysis of the flue gases is critical for efficient use of the fuels. Moreover, it is indispen-sable for clinker quality monitoring and emission protection. The concentrations of oxygen, carbon monoxide, and nitrogen oxides form the basis for optimizing burner operation, the use of fuels, and the product quality. Stable operation of the kiln and effective combustion mean a more efficient combustion process and less consumption of raw materials. Taking samples is no easy task at temperatures of more than 1400 °C plus high dust load in the gas sample and high concentrations of aggressive substances such as alkaline compounds, sulphates, and chlorides. In conventional, water-cooled flue-gas sampling probes, these substances clog the gas pipes due to condensation processes. Siemens has developed the Set FLK, which considerably reduces the expenditure for maintenance of the gas sampling installation. The probe does not use water for cooling. Instead, it uses a heat transfer fluid with a boiling point above 300 °C. This enables a gas sampling temperature of more than 180 °C, which is higher than the acid dew point of the flue gas. Condensation of the flue gas is thus prevented and substantially less condensate is formed, which results in less expenditure for cleaning.

The subsequent gas analysis provides information about the combustion processes. This data forms the basis for automated burner operation that ensures optimal fuel usage by regulating primary air flow, divergence, and rotation of the flame. Potential savings are enormous – after all, even one percent of excess oxygen leads to extra, unnecessary consumption of about 15 kcal per kilogram clinker.

5 Level measurement in the clinker cooler

To determine the filling level in the clinker cooler, contactless measurement – as used for the crusher filling level – is preferred because it requires much less maintenance. However, ultrasonic sensors are ruled out here due to the high temperatures and the extremely dusty atmosphere, a result of the strong damping characteristics of the flowing clinker that prevent reliable measurements. Some operations therefore resort to pressure gauges, which provide at least some information about the clinker filling level and thus the compressed air volume and throughput speed necessary for cooling. However, this method does not take into account the clinker density, which may vary and thus distort the results. To counteract this, many cement works use camera systems. The operator uses the camera images as a basis for a manual regulation of the speed at which the clinker travels through the cooler – a labor-intensive approach. Radar technology suggests itself for the implementation of an automatic control system for the clinker cooler. To solve this task precisely, Siemens is now also using 78 GHz frequencies in addition to the 25 GHz radar level measurement devices, which enables an even smaller antenna cone and even more precise measurements. The SITRANS LR560, a two-wire transducer with FMCW (frequency modulated continuous wave) technology, uses that frequency of 78 GHz. The short wavelength yields excellent reflections even for bulk goods with steep pile cones. Although this is not essential for the fill-level measurement in the clinker cooler, it makes the device suitable also for precise continuous level measurement in the clinker and cement silos.

The precise determination of the clinker filling level in the cooler forms the basis for automation of this process step and the optimal use of compressed air. And even a regular discharge of clinker without manual intervention and without interruption also means a stable and therefore efficient process in the kiln.

6 Flow measurement for grinding aids

Depending on the required degree of fineness, the in-feed grain size, the moisture content, and other factors, various grinding methods are used or combined in the final step of cement manufacturing. The addition of grinding aids has become standard practice and has several benefits. Additives increase the throughput, improve the energy efficiency, or influence the quality of the cement. This is achieved by the specific physical properties of the additives, most of which are liquid. They counteract the agglomeration of the cement particles by neutralizing electric surface charges and in this way prevent cement deposits in the mill, for example. The additives are added in amounts of between 0.01 and 0.2 % by weight, and must be precisely measured. As many grinding aids (for example, glycol or glucose syrup) are not conductive, conventional magneto-inductive flow meters cannot be used for that task. Therefore, Siemens uses mass flow meters such as the SITRANS FC430, the function of which is based on the Coriolis principle and offers an unrivalled measuring accuracy of 0.1 % of the flow rate over a wide measurement range. The SITRANS FC430 enables exact dosing with high availability rates. Because the devices have no moving parts, they are nearly maintenance-free. The precise metering of the grinding aids enables them to be used sparingly and is decisive for the quality of the product.

The use of reliable and precise process instruments for level and flow measurement and tailor-made gas analysis solutions for the cement industry make it possible to achieve a stable and efficient overall process even without extensive conversion measures. With more than 100 years of practice in the cement industry, and employees who have expertise in optimal application of appropriate measuring methods, Siemens helps optimize cement works around the globe – right down to the last detail.