Effects of oleochemical hydrophobing agents on plasters – results of a long-term field study

Even though the high efficacy of oleochemical additives as hydrophobing agents for mineral-based building materials has been proven by numerous laboratory tests there is a lack of measurements under field conditions. This paper will examine the results of various test specimens which were exposed to natural weathering for a period of up to three years.

1 Introduction

Oleochemical additives have been used successfully for decades as a hydrophobing agent for mineral-bound building materials. They can be used in a variety of ways in all kinds of products and exhibit good compatibility with other additives.

The effectiveness of the products in mineral plasters is tested in accordance with DIN EN ISO 15148 or DIN EN ISO 1015-18. Both methods measure the water absorption coefficients after the test specimens have been in defined storage for 28 days.

However, plasters and other building materials such as concrete are in no way static systems. After...

1 Introduction

Oleochemical additives have been used successfully for decades as a hydrophobing agent for mineral-bound building materials. They can be used in a variety of ways in all kinds of products and exhibit good compatibility with other additives.

The effectiveness of the products in mineral plasters is tested in accordance with DIN EN ISO 15148 or DIN EN ISO 1015-18. Both methods measure the water absorption coefficients after the test specimens have been in defined storage for 28 days.

However, plasters and other building materials such as concrete are in no way static systems. After 28 days the chemical-physical processes in these systems are still far from having ended. The capillary structure undergoes further changes and the hydration of cement and absorption of CO2 from the air continues. As a result, normally the strength of the building structure increases while its ability to absorb water continues to fall. Environmental influences such as pollutants, the growth of organisms, erosion or possibly salt bursts also have an adverse effect on the building materials.

Hitherto, only a small number of investigations have examined the effectiveness of hydrophobic treatment over a prolonged period. In the course of the present paper, the goal was therefore to investigate the persistence of different oleochemical hydrophobing agents under field conditions over a period of at least 12 months.

2 State-of-the-art

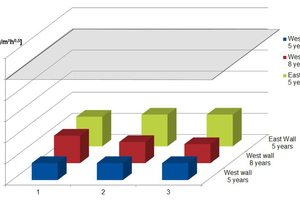

One of the first papers on the permanence of hydrophobized exterior plasters is by H. Künzel [1] at the Fraunhofer-Institut für Bauphysik in Holzkirchen. Samples were taken after five and eight years respectively from the plastered west and east walls of an experimental house in order to measure the capillary water absorption. As shown in Figure 1 the measured values were significantly below the limit of 0.5 kg/m² h0,5 and also exhibited a high degree of constancy over periods of five and eight years respectively. In contrast to a newly built plastered facade, the beading of water on the surface could no longer be observed after a few years. As the trials showed though, this is due to contamination of the surfaces from environmental influences. The measurement of water absorption by the test specimens showed that the hydrophobic treatment of the plastering mix was still fully effective (Figure 1).

In the course of her dissertation, B. Blachnik [2] devotes her attention to the permanence of additives in plasters and their leaching out. The hydrophobing agents used were a calcium stearate, a sodium oleate and an unspecified silicone. It was possible to show that the oleochemical hydrophobing agents exhibited better persistence when compared to the silicone. The investigations and storage took place under laboratory conditions. Besides the hydrophobization of the test specimens, the leaching out behaviour was also considered.

The protection of concrete against the effects of salt was investigated by W. Li [3]. It was possible to show that a 1 % dose of Ligaphob ZN 502 or Ligaphob ZN 101 Plus zinc stearate prevented the penetration of a 5 % sodium chloride solution well enough to create a usable chloride barrier.

In papers concerning calcium stearate and also primarily sodium oleate, Izaguirre [4] was able to show that the addition of 0.5 % to pure lime mortars significantly improved both workability and resistance to frost.

A further study [5] deals with the use of silane, calcium and zinc stearate as well as sodium oleate as additives to mineral mortar systems. While sodium oleate and silane exhibited good effectiveness after 28 days of curing, calcium and zinc stearate proved to be less effective. No more precise details regarding the quality of the stearates used are available. The mortar test specimens were subsequently stored for 4 hours in a 10 % solution of hydrochloric acid or else a mixture of salt and nitric acid (10 %). In this case, only the silane exhibited a rise in the mortars’ persistence compared to the untreated specimens. At this point, it should be noted that soaps and metallic soaps undergo hydrolysis at a pH value lower than 6. The relevance of this behaviour for mineral-bound mortar systems seems doubtful though.

The paper by Mukhopadhy [6] allows an indirect conclusion to be drawn about the persistence of hydrophobized plastering systems. It was possible to show that zinc stearate (dosage: 0.25 %) first and foremost provides hydrophobization accompanied by high water vapour permeability. Thus, not only is rain protection afforded but the building structure is able to dry out again thereby avoiding damage from frost. This effect was far more pronounced than in the case of the similarly tested silanes.

3 Theory of water absorption

Moisture penetrates into the building material essentially by three different transport mechanisms:

hygroscopic water absorption

condensation (temperature falls below dew point)

capillary water absorption

Of primary interest in relation to the present paper is the capillary water absorption. This is described by the capillary action equation, which in simplified form can be presented as follows:

H = (K2 x cos Θ) / r⇥(1)

H = capillary rise of the water [m]

Θ= contact angle between the liquid

surface and the capillary wall

K2 = constant [m²] including the surface tension,

acceleration due to gravity and density

of the liquid

r = radius of capillary [m]

The capillary absorption rate V at the start of the absorption process is directly dependent on the radius of the capillary r.

V = K1 x r (2)

V = capillary absorption rate [m/s]

r = radius of capillary [m]

K1 = constant [1/s]

It follows from the equations that a building material’s ability to absorb water increases as the radius of the capillary decreases. The speed of the initial suction however decreases. With non-hydrophobized building materials in particular, such as a control sample, the initial suction may be so high that the water absorption coefficient lies in the value range of water-repellent plasters. In the context of this discourse, a control sample is understood to mean an identical sample of plastering within a series without a hydrophobing agent. Therefore, besides the water absorption coefficient, the total water absorption (W24) must also always be considered.

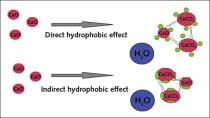

With hydrophobization of building materials, the polarity of the surface is reduced, which makes it harder to wet. The contact angle of a water droplet at the surface also diminishes. From a contact angle of 90° upwards, the cosine is negative causing capillary depression to take place and water is unable to penetrate the capillaries. Where the contact angle is lower than 50° the building material is very easy to wet. In between is a transition region in which specific characteristics of the considered material determine the wettability [7].

4 Design of the trials

The aim of the present study is to measure the chronological development of hydrophobization over a period of several years under the influence of the weather. Since samples have to be taken many times at fixed time intervals, sampling on a plastered surface has to be ruled out. It was decided to produce small discs of plaster according to DIN EN ISO 15148 and expose them to the weather standing upright in an outdoor space. After the discs were produced, they were sealed with a durable synthetic resin dispersion primer and a 10 mm thick polystyrene plate was applied to the rear to avoid condensation from forming on the rear side. To guarantee the durability of the lateral sealing, the side coating of the plaster discs was extended 5 mm beyond the edge on the front and rear sides. The finished plaster discs were mounted stress-free with a separation of around 10 mm on a waterproof panel by means of stainless steel holders. This should avoid any potential transfer of components of the fixing material, such as plasticizer escaping from plastics. The contact areas to the plaster disc were kept very small.

The discs could simply be dismounted to measure the absorption of water in the laboratory. Prior to the water absorption, the discs were conditioned. This was done by storing for three days at room climate. The conditioning in the drying oven influenced the absorption of water. As a check on the conditioning, the starting value of the dry plaster disc was used. An illustration of the plaster disc and its mounting can be gleaned from Figure 2.

Figure 3 shows the layout of the entire experimental trial. The plaster discs were placed facing south-westerly in the direction of the driving rain, between an administration building and elevated terrain. At one-month intervals the condition of the plaster discs was checked and the surface of the plastering was assessed visually. The entire weather data was recorded through a sensor, although for simplicity the mean monthly values were generated.

5 Weather data

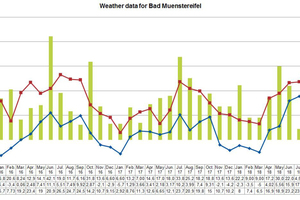

As shown in Figure 3, there is a weather sensor on one of the measuring stands to record relevant weather data. Of particular interest are the temperature profile and the monthly rainfall. In each case the temperatures represent the mean daily value. The highest and lowest mean temperature of each month is recorded.

The measured values are shown in Figure 4. With a mean rainfall of only 40 to 80 mm per month, Bad Münstereifel is one of the regions with poorer rainfall. In the course of a normal year, July is the warmest month and usually about 16 °C warmer than the coldest month, January [8].

Compared to the normal weather progression, there were two noteworthy features within the period under investigation: Spring 2016, especially June, was subject to heavy rainfall, whereas July, August and September of 2018 experienced an exceptionally hot and very dry summer.

The results of the capillary water absorption were not indicative of these noteworthy events even though, for example, the damp late spring of 2016 might have resulted in the growth of micro-organisms on the plastered surface. Surface assessment of the plaster discs revealed nothing conspicuous.

6 Results

6.1 Trial series I

Since the number of available measuring places is limited, several series were measured. The first data collection was from five test specimens, each of which consisted of an adhesive and reinforcing compound with different hydrophobing agents. Reactive products, non-reactive products and combination products were used as hydrophobing agents. To produce the test specimens, the non-hydrophobized adhesive and reinforcing compound was mixed with the hydrophobing agents in the Hobart mixer. Water absorption of these plaster discs was measured following DIN EN ISO 15148. They were then placed outdoors for exposure to the weather as described in Chapter 4.

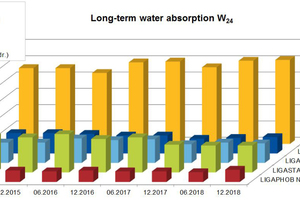

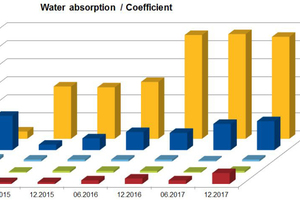

The results of the series of trials are shown in Figure 5. With this type of plaster the demand on the hydrophobization is far less than with many finishing plasters. Thus, very good results can be achieved even with a low dose of hydrophobing agent, in this case 0.3 %. Within the scope of measurement accuracy, the resistance to weathering of the products used can be described as very good. No distinct deviations are noticeable on the test specimens over the period of 3 years. Merely the control sample - the non-hydrophobized plaster disc - exhibits a distinct rise in water absorption coefficient.

As is evident from observation of the total water absorption (W24) in Figure 6, this applies only to the speed of water absorption. The W24 values are almost identical. Since the pore structure is no longer moved towards larger radii, a higher polarity of the pores has to be assumed. This is founded on newly formed surfaces due to carbonatization or further hydration of cement fractions.

Whilst the calcium stearate Ligastar CA 860 exhibits rather good hydrophobization, it does not reach the standard of the Ligastar ZN 101 or the Ligaphob product range developed specifically for building protection.

6.2 Trial series II

In a further series of trials, the combination of an adhesive and reinforcing compound and a finishing plaster, in the present case a thin-layer finishing plaster, was to be observed. Discs of plaster approximately 2 cm thick were similarly produced for this purpose. However, in addition to the discs based only on adhesive and reinforcing compound or only on finishing plaster, discs were also produced made of a combination of finishing plaster and adhesive and reinforcing compound. A control sample without hydrophobing agent was also measured for each of the separate plasters. The results are shown in Figure 7.

The non-hydrophobized plasters exhibit a distinctly increased water absorption. With the finishing plaster one finds two step changes: One after the first six months of weathering and one after the spring of 2016, which was subject to increased rainfall. At the same time, in the conditioned state this sample had the highest weight gain. This suggests the formation of new surfaces takes place in the plaster due to carbonatization and hydration.

The adhesive and reinforcing compound, on the other hand, initially exhibits a distinct decline in water absorption followed by a continuous, moderate climb throughout the entire duration of the trial. In both cases this effect is inhibited by the use of hydrophobing agents. This demonstrates that even newly formed surfaces do not influence the absorption of water. The plaster sample from the combination of the two systems exhibits constant values, with the exception of the last measured value in winter 2017. Whether or not this was an outlier could not be established.

In total, it is evident that hydrophobization with the help of oleochemical products exhibits very good long-term stability over the period of three years.

6.3 Trial series III

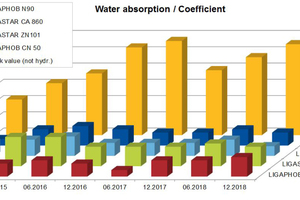

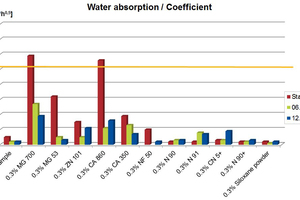

In a third series of trials, a larger number of products were then tested on a standard plaster. For this purpose, a lime/cement plaster with overall 17 % binding agent content and 10 % limestone powder was used. The mixture also contained a surfactant air-entraining agent and a methylcellulose. In an initial series of trials, reactive and non-reactive hydrophobing agents as well as combination products with an addition level of 0.3 % were tested. The results are displayed in Figure 8.

The non-reactive hydrophobing agents are based on metallic soaps. Products which were produced according to the precipitated production process [9] (Ligastar CA 350 / ZN 101) are contrasted alongside products from the direct conversion (Ligaphob MG 700, Ligastar CA 860). It can be clearly seen that the non-reactive hydrophobing agents require a slightly higher dosage than the combination products or the reactive hydrophobing agents. Again, compared to Ligastar ZN 101 and Ligastar CA 350, the products Ligaphob MG 700 and Ligastar CA 860 exhibit higher water absorption. This illustrates the superiority of the products produced by the precipitation method. The initial value for Ligaphob MG 53 lies between these two types of products and exhibits distinctly better values. This product is a magnesium stearate specially developed for building protection and is produced by a modified direct production process. Particularly noteworthy is the marked improvement in the water absorption coefficient after weathering for one year.

The reactive products [10] (Ligaphob N 90 / N 91 / N 90+) as well as the combination products (Ligaphob CN 5+ / NF 50) generally exhibit slightly better values or, in other words, allow a lower dosage. Ligaphob N 90 and Ligaphob N 90+ offer the best performance and are comparable to the siloxane powder.

Differences in the region below 0.1 kg/m² h0,5 are difficult to judge though and require a longer trial evaluation. Dirt on the surface, for example, is one effect that influences the measurement. This is usually removed though in the course of the measurement over 24 hours and leads to slightly improved values at the next measurement. However, mechanical cleaning of the surface prior to the measurement falsifies the results, as the trials revealed. Therefore, this particular measure was omitted.

Noticeable is the good value of the water absorption coefficient for the control sample without hydrophobing agent. The reason for this is the very strong initial suction of the sample. The type of plaster used sucks water up within a few minutes until the capillary system is saturated. This indeed results in a slight slope of the straight line in the graphical evaluation of water absorption and hence a lower water absorption coefficient. Therefore, both the water absorption coefficient (w) and overall water absorption (W24) are crucial for the assessment of a hydrophobing agent.

7 Summary and outlook

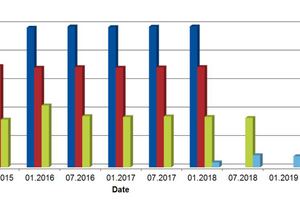

Several series of trials were carried out between 2015 and 2018, in which plastering discs were produced with different types of plaster as well as with different hydrophobing agents and subjected to outdoor weathering. In each instance a control sample was also used that contained no hydrophobing agent. The weights of this sample in the conditioned state are portrayed in Figure 10.

On average, a weight gain of about 20 g can be recorded during the first 6 to 12 months of weathering. This is undoubtedly due to the carbonatization and further hydration.

Following the series of trials, the control samples were stored in a dry place for an extended period and subsequently post-dried in a dry cabinet at 90 °C. This resulted in a weight loss of around 2 g. From this it can be concluded that water has not been stored as water of crystallization but instead was bound permanently into the structure. With the hydrophobization this process is not perceptible.

It is further planned to extend trial series II over a period as long as possible. The limiting factor is the degradation of the plaster discs. Plaster systems suffer deterioration due to biological or chemical corrosion as well as physical damage due to penetration by frost. This particularly applies to the plastering discs erected in isolation. Work on improving the method will also be undertaken. Testing is currently being done to see whether the surface of the discs can be cleaned with a water jet prior to the conditioning.A further series of trials to investigate the influence of the C chain distribution on the hydrophobization as well as further additivation is currently in preparation.

An important outcome of the trials remains the finding that the hydrophobization of various plasters by means of oleochemical products exhibits very good long-term stability even under the influence of weathering. No impairment could be found either in the condition of the surface or in the measured values for the water absorption coefficients.

//www.peter-greven.de" target="_blank" >www.peter-greven.de:www.peter-greven.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.