Ecological comparison between hydrated lime and sodium bicarbonate when used for dry flue gas purification

Lime plays an important role in environmental protection. Not only due to its properties but also due to its natural occurrence, it is suitable and accepted for universal application in the environment sector. Lime and its refined products can be used in various processes to remove the acid gases, the gaseous metal compounds and organic trace constituents from the flue gas of waste incineration plants. The choice of the suitable process depends on the raw gas load, the separation efficiency to be achieved and the way of recovery of the reaction product obtained as a result of flue gas...

Lime plays an important role in environmental protection. Not only due to its properties but also due to its natural occurrence, it is suitable and accepted for universal application in the environment sector. Lime and its refined products can be used in various processes to remove the acid gases, the gaseous metal compounds and organic trace constituents from the flue gas of waste incineration plants. The choice of the suitable process depends on the raw gas load, the separation efficiency to be achieved and the way of recovery of the reaction product obtained as a result of flue gas cleaning.

The dry sorption processes have been established for many years and have been continuously further developed, in which lime is injected into the flue gas flow and the reaction product is retained via a filtering separator. As an alternative to lime products, it is also possible, under certain boundary conditions, to use sodium hydrogen-carbonate NaHCO3 (below called sodium bicarbonate) as basic reaction component in the dry sorption process. As opposed to calcium hydroxide, there are differences, for example as regards the reaction temperature required and the necessary amount of sorbent to achieve the desired purification effect.

Due to the higher reaction temperatures of the sodium bicarbonate, energy can be saved in the common selective catalytic NOx-reduction process (SCR process) since a lower temperature difference has to be overcome when heating up the flue gas before the corresponding catalysts. Furthermore, the amounts of residual products yielded when using sodium bicarbonate are lower than with the use of hydrated lime. In the past this led to the impression that sodium bicarbonate is the ecologically more useful flue gas additive. However, an assessment from the ecological point of view must be more comprehensive and must also include the manufacturing process of the different feed materials. For this reason, at the Munich Technical University, department of raw material and energy technology – Prof. Faulstich, carried out an ecological comparison of both sorbents.

Two plant configurations were investigated as reference scenarios for the ecological evaluation of both flue gas additives. Both are based on a conditioned dry sorption using a reactor or a quencher, respectively, and a fabric filter. They differ in the kind of the denitrification process (SCR and SNCR). For hydrated lime they assumed a reaction temperature of 140 °C and for sodium bicarbonate it was 180 °C.

Based on the consideration of all process steps from manufacturing to flue gas cleaning, the ecological impact of both additives has been derived with the help of various categories of impacts. The evaluation of the efficiency is based on the following impact categories:

– greenhouse effect,

– acidification,

– eutrophication,

– energy consumption and

– raw material consumption, as well as

– on the additional evaluation parameters

• residuals and

• amount of overburden

using the corresponding standardized impact factors.

Result

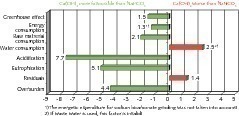

The use of hydrated lime has a predominantly positive impact compared to the use of sodium bicarbonate in the scenario investigated with SCR (Fig. 1). Only as regards the amount of residuals, sodium bicarbonate has a slight advantage. In this impact category both additives have the same effect if waste water is used for cooling the flue gas to reaction temperature instead of process water. However, the inorganic salt load resulting from the production of bicarbonate, which is discharged via the medium water, has not been taken into account because it cannot be categorized. The acid chloride load is converted into neutral salt and is discharged via the receiving water. Related to 1 t of waste, almost 25 kg of inorganic salts are discharged via water during the production of the amount of sodium bicarbonate, which is later needed for purification.

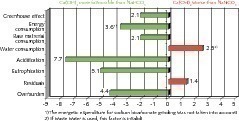

As regards the investigated alternative scenario with SNCR, the ecological advantage of hydrated lime is more obvious since the energy consumption and the associated emissions with a climatic effect are reduced due to a superfluous reheating of the flue gases (Fig. 2).

Conclusion

A decisive criterion for the evaluation of the results is the relevance of the corresponding impact categories. In the study by the Munich Technical University the impact categories greenhouse effect, energy and raw material consumption had top priority. The results of the reference scenarios investigated with SCR plants have shown that the use of hydrated lime is ecologically more worthwhile as regards the greenhouse effect and the energy consumption. However, changes of the input parameters and plant configuration may also lead to changed results. The higher the stoichiometric factor for the use of hydrated lime, the worse is the active substance of hydrated lime and the more energy is needed for reheating of the flue gases and, consequently, the more emissions harmful to the climate are generated during reheating then the more unfavourable the result will be.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.