Cement and CO2: What’s happening?

The presented paper won first place at the recent IEEE-IAS/PCA Cement Industry Conference in Washington, DC. This paper is a follow-up to the previous award winning paper “Cement and CO2: A Victim of Success” that was presented at the San Antonio conference in 2012.

1 Introduction

The majority (about 60 %) of the CO2 emitted from a modern cement plant comes from the calcination of limestone. The remainder comes primarily from the fuel combustion required to drive the clinkering reactions in cement manufacture. Table 1 demonstrates a typical CO2 balance for a modern cement plant.

2 Traditional levers

There are three highly publicized, traditional levers for reducing CO2 from conventional cement manufacturing:

Fuel efficiency

Biogenic fuels

Clinker substitution

These have been widely explored and publicized in the media. Table 2 provides an insight into how some...

1 Introduction

The majority (about 60 %) of the CO2 emitted from a modern cement plant comes from the calcination of limestone. The remainder comes primarily from the fuel combustion required to drive the clinkering reactions in cement manufacture. Table 1 demonstrates a typical CO2 balance for a modern cement plant.

2 Traditional levers

There are three highly publicized, traditional levers for reducing CO2 from conventional cement manufacturing:

Fuel efficiency

Biogenic fuels

Clinker substitution

These have been widely explored and publicized in the media. Table 2 provides an insight into how some of the major international cement manufacturers are performing according to these three levers.

Clinker substitution has a direct impact on carbon footprint. One of the main drawbacks for increasing clinker substitution is the apparent lack of good supplemental cementitious materials. Table 3 estimates the maximum amount of clinker substitution available for blended cements today.

However, it is clear that these three levers alone will not allow cement production to meet the International Energy Agency’s (IEA) Blue Map target for 2050, of approximately 340 kg CO2 per ton of cement produced (Fig. 1). The Cement Sustainability Initiative (CSI) has developed a roadmap for reducing CO2 emission in conjunction with the IEA. The roadmap identifies a large gap in meeting the 2050 target with the traditional levers alone and indeed indicates that carbon capture and sequestration (CCS) will be required for over half of the called for reductions.

3 Clinker reformulation

As the three traditional levers will not meet the IEA target, several of the major multinational cement manufacturers have been working on new clinker formulations to further reduce the carbon footprint of cement. The exact approach varies between the different producers, but there are two common themes: less limestone in the raw mix and lower heat of reaction. These two areas can drop the CO2 per ton of clinker by another 20 to 30 %. Each manufacturer has their own specific means for achieving these objectives. A summary of the new formulations is provided in Table 4.

4 Carbon capture

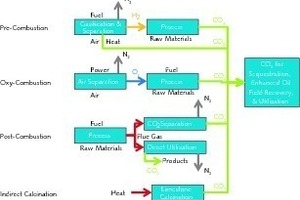

Even with this new “fourth” lever there will be a need for additional CO2 emissions reductions. In this case separating the CO2 from the flue gas may be necessary. This process is commonly referred to as carbon capture. The CO2 is considered to be sequestered when the captured CO2 is stored underground. There are several areas that are being investigated for CO2 capture as seen in Figure 2.

Pre-combustion technologies are probably not beneficial for cement manufacture as the majority of the CO2 emissions come from the process and not the combusted fuel. Oxy-combustion is interesting from the standpoint that partial oxy-combustion or oxy-calcination can result in approximately 80 % of CO2 capture with a much lower investment than complete oxy-combustion. However, oxy-combustion and oxy-calcination are best suited for newly constructed cement plants, specifically designed for these processes. Indirect calcination implies calcining the limestone/raw meal without direct contact with combustion gases. This will also require specifically designed processing equipment. Table 5 compares some of the differences between oxy-combustion processes and indirect calcination. The yield is defined as the tons of CO2 captured per ton of O2 consumed.

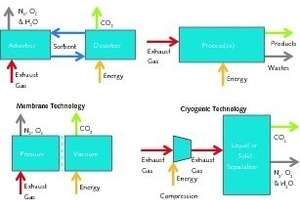

Oxy-combustion and indirect calcination are most applicable to new installations, that leaves post-combustion technologies as the most likely solution for existing plants. These “tail pipe” technologies will be added to the back end of existing and new facilities, after all of the traditional manufacturing steps are taken. There is a tremendous amount of work being done on post combustion technologies for all industries around the world. The basic research falls into three main categories for carbon capture:

Sorbent technology

Membrane technology

Cryogenic technology

The fundamentals of these technologies are shown in Figure 3.

Sorbent technology consists of utilizing a sorbent to attach/extract the CO2 from the flue gas stream in one chamber. This sorbent is then treated in a separate chamber to release an almost pure CO2 stream. Depending on the sorbent a combination of temperatures, pressures, and chemical reactions may be used to release the CO2 from the sorbent. The most widely used and accepted sorbents are amine solutions. This type of process has been in use for gas cleaning for many years and is fairly well understood, although new, more efficient sorbents are being developed on a continual basis. Recent work has also focused on solid sorbents. An amine project is being piloted in a cement plant in Norway along with a solid sorbent trial.

One sorbent process that is very interesting for the cement industry is the use of lime (CaO) as a solid sorbent (“carbonate looping”). The lime is introduced to the CO2 in the gas stream and recarbonizes, adsorbing the CO2 from the gas stream to revert back to CaCO3 (CaO + CO2 => CaCO3). The captured CO2 can be released in almost pure form by reheating the CaCO3 in a separate vessel. This process is not very effective for other industries as the lime sorbent does not regenerate well and therefore needs a relatively high level of replenishment. This is not as much of an issue for cement manufacture as the spent sorbent would become part of the cement manufacturing raw materials. A pilot carbonate looping project has been installed in a cement plant in Taiwan.

Membrane technology consists of separating CO2 from flue gases via a pressure differential across a semi-permeable membrane. The membrane is designed to allow only CO2 to pass through. Membranes are often used with pressure on the dirty side and vacuum on the clean side to pull as much CO2 through the membrane as possible. The membrane technology has been proven to work and deliver a highly concentrated CO2 stream. However, large membrane areas are required and membrane life is still unacceptable. Membranes deteriorate due to reactions with other constituents in the gas stream including acid gases and dust. There is a membrane pilot project ongoing in a cement plant in Norway.

Cryogenic technologies rely on the different boiling and freezing points of the main gas components to separate one or more of the individual gas streams. CO2 is particularly interesting as it is one of the few gases that have a triple point where the gas can easily pass from gas phase to either liquid or solid phase within a narrow range of temperatures and pressures. Cryogenic processes typically rely on gas compression and expansion to create temperature differences that will cause the phase changes that enable the gas separation. One advantage that cryogenic separation might have is that the captured CO2 could be in liquid form and thus easier to transport in situations where CO2 pipelines do not exist.

5 Carbon utilization

Utilization technologies convert the CO2 into another, usable form. There are many utilization technologies proposed and in the works today. By far the most research from cement manufacturers according to the sheer number of projects is in algae cultivation. The latest count indicates at least 14 algae type projects that either have been completed, are in progress today, or are planned for the near future. The basic premise of the algae projects is to use the cement manufacturing flue gas as a feed stream for algae that can be cultivated and converted into useful end products. A summary of ongoing algae projects is presented in Table 6.

The majority of algae projects appear to be concentrated on producing some type of bio-fuel, most often referred to as bio-diesel. However, a handful of companies have recognized that there are higher value added products created by the algae that could also create a higher return on investment. To date most algae projects have proven two things:

Certain algae strains can survive and thrive in cement plant flue gas, and

The energy/CO2 required to capture the CO2 is greater that the energy/CO2 saved

Therefore the existing algae technologies are not cost effective today. However, a few breakthroughs from now and this could become a very interesting area.

6 Summary and Conclusions

Good progress is being made on several fronts in the efforts to reduce the cement industry’s carbon footprint. All of the major international cement producers are publishing their results on an annual basis. More specific information can be found from these companies’ sustainability reports.

Even though good progress has been made, more is required. The major producers know that and are working towards further reductions in all areas. It is most likely that carbon capture and carbon utilization technologies will be required to meet the IEA/CSI 2050 Blue Map target of around 340 kg CO2/t cement.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.