Calcium sulfate composite

binders containing pozzolans for

use in planar products

The aim is to produce planar products based on calcium sulfate composite binders. In initial trials it was demonstrated that (up to five-times) higher strengths can be achieved with this mixed binder than with pure hemihydrate plaster mixes for the same water/binder ratio. The strength losses caused by moisture that are typical of calcium sulfate can, depending on the mix formulation, be significantly reduced so that they can be lowered to the same level as cementitious systems. The timing of expansions caused by ettringite can be controlled by suitable mix formulations so that they are completed within 7 days at the latest.

1 Motivation

The results described here were obtained during a ZIM research project with the partners Lindner AG, GiB Gesellschaft für innovative Bautechnologie mbH and the F.A. Finger Institute for Building Material Engineering at Bauhaus-Universität Weimar. This partnership is developing fibreboard based on special, energy-efficient, calcium sulfate composite binders.

This binder system consists of calcium sulfate binders that are capable of setting and have a low primary energy requirement with properties that can be sustainably improved by carefully controlled combinations with cement and...

1 Motivation

The results described here were obtained during a ZIM research project with the partners Lindner AG, GiB Gesellschaft für innovative Bautechnologie mbH and the F.A. Finger Institute for Building Material Engineering at Bauhaus-Universität Weimar. This partnership is developing fibreboard based on special, energy-efficient, calcium sulfate composite binders.

This binder system consists of calcium sulfate binders that are capable of setting and have a low primary energy requirement with properties that can be sustainably improved by carefully controlled combinations with cement and pozzolans.

The use of these special binders is of particular interest in areas where conventional fibreboard bonded solely with calcium sulfate or cement exhibits disadvantages because of technical and/or economic factors during its production, processing or application. The advantage of this composite binder based on calcium sulfate is that it combines the beneficial properties of cement with those of the calcium sulfate binder.

Cementitious systems exhibit very good moisture resistance and strength but have a tendency to shrink, i.e. the shortening of the boards caused by drying, which under some circumstances can lead to cracking. They also hydrate and dry significantly more slowly than calcium sulfate building materials. This means that not only is a high level of drying energy required but also that adequately dimensioned storage capacity is needed to ensure complete hydration.

Calcium sulfate binders, on the other hand, are substantially dimensionally stable, dry rapidly and have beneficial ecological properties with respect to the binder because the energy expenditure for their production is up to 10 times lower, and the climatically relevant CO2 emissions are up to 20 times lower, than with cement. However, the low moisture resistance is a disadvantage.

The intention was to develop mixed binder systems for use in planar products because of their beneficial properties, such as the environmental friendliness through the use of energy-efficient and sustainable raw materials, the increased moisture resistance and the crack-free hardening.

The increasing demand for ecological products that conserve resources gave rise to the idea of developing system solutions with the planar material described above.

Damp spaces form an important area of application for these planar building materials. These are spaces where condensing conditions can sometimes be expected. Such climatic conditions can also arise during the construction phase. Gypsum fibreboard cannot be used under these conditions because of its low moisture resistance, so cement fibreboard is used under these circumstances.

Extensive enquiries have shown that these composite binders have not so far been used in such technically highly developed processes for producing the boards so there is a need for specific research in this area.

2 Current state of science and technology

2.1 Calcium sulfate composite binders

Calcium sulfate composite binders consist essentially of a calcium sulfate binder with setting properties, a cementitious (or “CaO-donating”) component and a pozzolanic (“CaO-absorbing”) component. These constituents must be precisely adjusted with respect to their reactivity and the specific application to ensure dimensionally stable hardening. If the mix is not carefully formulated then the durability of the hardened binder can be adversely affected by massive ettringite formation. However, with a balanced mix it is possible to combine the beneficial properties of the cement (especially water resistance and high strength) with those of the calcium sulfate binder (favourable swelling and shrinkage behaviour) [1, 2, 3].

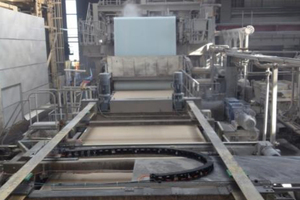

2.2 Production technology for planar products

The planar products are to be produced on the moulding machine belonging to Lindner. The moulding machine consists of a lower longitudinal sieve that assists the dewatering and thickness calibration through an additional upper sieve belt in a wedge-shaped configuration. The boards are produced as a continuous strand in this moulding machine by gravimetric and vacuum-assisted dewatering and are cut to the required master board format with a water jet before setting. Figure 1 shows the discharge of the boards from the moulding machine (upper sieve visible), the continuous strand and, in the front of the picture, the board that has been cut to shape.

This production has the following advantages over the Hatschek process (standard plant for producing cement fibreboard in accordance with EN 12467):

also functions with rapid-setting products (absolutely essential with GCP binders)

no layer bonding problems

lower bulk density can be achieved by addition of lightweight aggregates

variable board lengths (no formatting roller needed as in the Hatschek process)

only 20 % water recirculation when compared with the Hatschek process

3 Specifications and starting materials

3.1 Starting materials

Possible starting materials that appeared chemically and economically suitable were specified jointly by the partners for the boards to be developed. The binder components that were most suitable for the specific application were determined in preliminary investigations.

Hemihydrate plaster (stabilized and retarded at the factory) was used as the source of calcium sulfate and a CEM I 52,5 R Portland cement served as the cementitious component. A large number of pozzolans were investigated in advance for their suitability. An aluminosilicate pozzolan was selected for further investigations on the basis of the suitability test that had been developed.

4 Test procedure

Expansion of the calcium sulfate composite mixes occurs due to the formation of ettringite. The main expansion should be completed within the first 7 days. This was checked by measuring the change in length. Three prisms (40 x 40 x 160 mm) with pegs for measuring shrinkage were produced in each case. These were removed from the moulds after 24 hours and stored above water (100 % air humidity at 20 °C). The changes in length were measured daily until the 14th day. The test pieces consisted of pure binder paste. The intention was to investigate the time at which the changes in length reached their maxima.

The prisms for the strength tests were produced and stored in the same way as those for measuring the change in length. The compressive strengths were determined after 7 days on each of two test pieces. The strengths were determined not only on moist test pieces but also on test pieces that were dried to constant mass at 40 °C before the test. The comparison is used for preliminary investigative examination of the drop in strength induced by moisture that is typical of calcium sulfate binders. As this involves pure binder pastes these results also make it possible to estimate the strengths that can be achieved. The flexural tensile strengths are not shown as they are crucially influenced by the fibre reinforcement.

Statistical test planning methods were employed for the investigations. A centrally compiled test plan was used for the tests of strength and change in length. The influencing variables are listed in Tables 1 and 2.

The mixes were retarded with Retardan and a w/b ratio of 0.51 was used to ensure workability. A hemihydrates plaster reference material (100 % hemihydrate plaster, w/b = 0.51) and a cement reference material (100 % CEM I 52,5 R, w/c = 0.44) corresponding to the calcium sulfate composite mixes were produced and investigated for comparison purposes.

5 Results and evaluation

5.1 Preliminary comment

The tests were designed and evaluated with the aid of statistical test planning. The data were used to derive models, which are shown below in the form of graphics. The summary of the ANOVA (analysis of variance) is confined to the most important results.

5.1.1 Changes in length after 7 days

Table 4 shows the ANOVA evaluation of the change-in-length measurements. The raw data had to be transformed for the variance analysis (y’ = 1/√y) to achieve a normal distribution of the residuals. A significant quadratic model was obtained for both the target variables investigated.

The results show that the changes in length of all the mixes (except for Run 2) had reached their maxima within the first 7 days, so the objectives were fulfilled. This duration is heavily dependent on the pozzolan/cement; the time required to reach the maximum change in length falls with increasing ratio (Figure 3). The proportion of hemihydrates plaster has comparatively little influence here.

However, a significant interaction was determined (Figure 3). It is only at a low pozzolan/cement ratios that the proportion of hemihydrate plaster has a (slight) effect on the time until the length stops changing. At a pozzolan/cement ratio of 1 the time shortens with rising proportion of hemihydrates plaster but no significant influence of the proportion of hemihydrates plaster was found at higher ratios.

The model for the maximum values of the changes in length is shown in Figure 4. It was established that the maximum expansions increase with rising proportion of hemihydrates plaster and with decreasing pozzolan/cement ratio.

It should be borne in mind here that the changes in length that occur are also heavily dependent on the storage conditions (especially the moisture). The values shown here with, in some cases, very large expansions were measured during storage over water (100 % air humidity) and do not occur to this extent under normal climatic conditions. In spite of this these expansions are not destructive (no cracks, increasing strength).

5.1.2 Strengths after 7 days

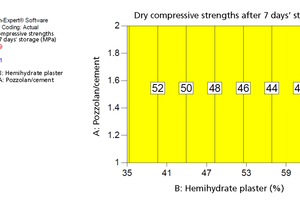

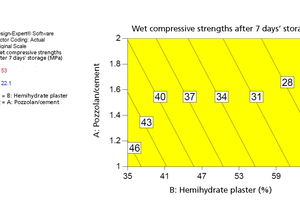

The ANOVA evaluation is summarized in Table 1. A highly significant linear model emerged for all the target variables considered.

It is clear that significantly higher wet, and also dry, compressive strengths can be achieved by the addition of the cementitious and pozzolanic components than with pure hemihydrates plaster (at the same water/binder ratio of 0.51 (Figures 5, 6 and 7)). The strengths exceed those of the hemihydrates plaster reference material by a factor of more than 5 for the dry strengths and by a factor of more than 2.5 for the wet strengths (hemihydrates plaster: dry compressive strength 20.8 MPa; wet strength: 10.1 MPa, strength loss due to moisture: 51.4 %). With all the mixes the strength loss due to moisture is (in some cases significantly) lower than with the hemihydrates plaster reference material.

The dry strengths are lower than with the cement reference material (cement: dry compressive strength: 57.4 MPa; wet strength: 48.2 MPa, strength loss due to moisture: 16.1 %). However, higher wet strength values were achieved in some cases with the calcium sulfate composite binder (in spite of a higher w/b ratio).

In the test conditions under consideration the dry compressive strengths are significantly dependent only on the proportion of hemihydrates plaster and fall with increasing proportion (Figure 5).

On the other hand, the wet strengths are dependent on both the pozzolan/cement ratio and the proportion of hemihydrates plaster (Figure 6). In this case the compressive strength rises with decreasing proportion of hemihydrate plaster and with falling pozzolan/cement ratio. The lowest values for the drop in strength due to moisture occur with a low proportion of hemihydrates plaster and low pozzolan/cement ratio (Figure 7). All mixes exhibit a lower drop in strength than the hemihydrates plaster reference material and in the most favourable case are at the same level as the cement reference material.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![2 Time taken to reach the maximum change in length of the mixes [in days]](https://www.zkg-online.info/imgs/1/3/6/2/2/6/8/tok_6af5d75bc49548a65ab4a090b8176327/w300_h200_x600_y321_2-c1154f8dd205401d.jpeg)

![3 Interaction between the pozzolan/cement ratio and the proportion of hemihydrate plaster on the time taken to reach the maximum change in length of the mixes [in days]](https://www.zkg-online.info/imgs/1/3/6/2/2/6/8/tok_3d950bbea88960dbf1a00536ee064beb/w300_h200_x600_y323_3-fdb449e7502c13fc.jpeg)

![4 Maximum values of the changes in length [mm/m]](https://www.zkg-online.info/imgs/1/3/6/2/2/6/8/tok_9f85316bc72700c137dd96de40e5745c/w300_h200_x600_y310_4-9ea723de35f5fb5f.jpeg)

![7 Drop in strength [%] due to moisture in a comparison of dry and wet strengths after 7 days](https://www.zkg-online.info/imgs/1/3/6/2/2/6/8/tok_5d3e8ad6f2213b3da11fcfdef85f165d/w300_h200_x600_y340_7-610543bdc9b4ed72.jpeg)