A greener brownfield

Through an extensive modernization project that combined new technologies with sustainability and involved upgrading the process control systems with a state-of-the-art industrial network, the Italcementi Group has not only improved the productivity and efficiency of its Rezzato plant, but has also built the foundations for future innovations.

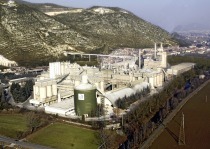

With a production capacity of 61 million tons per year and subsidiaries on four continents, Italcementi Group is one of the world’s largest cement producers. The company has repeatedly won awards for its commitment to innovation and sustainability, and continually sets new standards – for example, with the modernization of its plant in Rezzato, Italy, originally put into operation in 1964.

A step into the future

The Rezzato project, given the green light in 2010, is proof of Italcementi’s future orientation. One of the company’s main objectives was to transition from a semi-dry clinker...

With a production capacity of 61 million tons per year and subsidiaries on four continents, Italcementi Group is one of the world’s largest cement producers. The company has repeatedly won awards for its commitment to innovation and sustainability, and continually sets new standards – for example, with the modernization of its plant in Rezzato, Italy, originally put into operation in 1964.

A step into the future

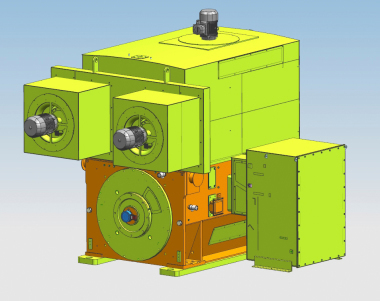

The Rezzato project, given the green light in 2010, is proof of Italcementi’s future orientation. One of the company’s main objectives was to transition from a semi-dry clinker manufacturing process to a modern, more energy-efficient, and sustainable dry process. For the automation and process control of the new line, Italcementi chose Simatic PCS 7 – as it had for various successful installations in the past. The complete engineering, supply, and commissioning of this main control system (MCS) was awarded to Fast S.p.A., an experienced automation services provider and systems integrator for Siemens.

New possibilities with Profinet

Because the assets of a cement plant are often dispersed over a wide area, the design of the communication network architecture is a critical issue in MCS engineering. Normally, a centralized layout is the solution of choice – with all smart devices located near the central control room, all peripherals in the distributed electrical rooms, and all the devices connected via a Profibus DP–based star or ring network.

Rezzato chose a different approach and became the first project worldwide to use a unique Profinet ring with Simatic PCS 7, which connects all the controllers to all the Profinet users. This solution, devised by C.T.G. (Italcementi Group Technical Center), was designed by Siemens and Fast S.p.A. and significantly simplifies the network architecture. Any peripheral device in any electrical room can be connected to any MCS controller, anywhere in the plant – simply by means of optical fibers. In addition, it is possible to easily link third-party local programmable logic controllers (PLCs) into the network and to access them for maintenance or service from wherever an engineering station is plugged in.

More than one reason to celebrate

During the installation and commissioning of the system, experts from CSMT (Centro Servizi Multisettoriale e Tecnologico – the Profibus and Profinet Competence Center headquartered at the University of Brescia) conducted extensive surveys and performance audits and also assisted in the detail engineering phase. With their diagnostic tools, they could examine all network nodes, resolve connection and configuration issues, and release network performance certification reports.

Thanks to the close collaboration of all the participants, the modernization project was a big success. The Rezzato facility, which began operating in 1964 during the 100th anniversary of the founding of Italcementi, started up its new line in November 2014 in time for the 150th anniversary.

//www.siemens.com" target="_blank" >www.siemens.com:www.siemens.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.