Operating experience with the new Polysius-Quadropol2 raw mill

The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small construction size and high availability. These are precisely the performance characteristics of the new roller mill generation from TKIS. ZKG reports now about operating experiences with the latest mill version.

1 Introduction

In 1999 the Polysius roller mill Quadropol was introduced onto the market with the target to offer a vertical roller mill (VRM) of highest reliability which allows feeding of a 10 000 tpd clinker line by a single mill. After many...

The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power combined with small construction size and high availability. These are precisely the performance characteristics of the new roller mill generation from TKIS. ZKG reports now about operating experiences with the latest mill version.

1 Introduction

In 1999 the Polysius roller mill Quadropol was introduced onto the market with the target to offer a vertical roller mill (VRM) of highest reliability which allows feeding of a 10 000 tpd clinker line by a single mill. After many references in 2008 for Gulf Cement in the United Arabian Emirates a Quadropol QMR 61/30 with an installed drive power of 7000 kW was commissioned, and thus was the world’s largest vertical roller mill at that time.

Meanwhile the first Quadropol of the 2nd generation for raw material grinding, the QMR2, has been successfully commissioned. This QMR2 43/21 is part of a new 3000 tpd cement kiln line which started production in 2012 in the Balsa Nova works of Cia. de Cimento Itambé near the city of Curitiba in Southern Brazil.

2 Improvements

Beside the advantages of the QMR2 in general the main advancements of the new Quadropol can be summarized as follows:

A simplified design to increase the reliability and to ease maintenance

Reduced weights of the roller units for easier handling and higher competitiveness

Tangential hot gas inlet and a circumferential nozzle ring for optimized gas flow and material distribution to the separator and thus better separating efficiency

Simplified foundation with improved damping effect for smooth operation

Figure 1 shows the flowsheet of the raw material grinding plant. From the feed hoppers for limestone, clay, quartzite and iron ore the raw materials are proportioned by weighbelt feeders and then carried by a belt conveyor to the grinding plant. Via a further belt conveyor and a coarse feed valve which simultaneously serves as an airlock device the raw material enters into the mill.

Protection against tramp metal is provided by a suspended magnetic separator installed over the belt conveyor after the feed hoppers. A metal detector detects metallic objects and activates a change-over flap which directs the raw material containing the metallic object to a bin from where the material is withdrawn by a short belt conveyor at low speed. An additional metal detector activates a change-over flap to dump the smallest possible amount of raw material. The portion free of metallic objects is passed to the fresh feed of the mill.

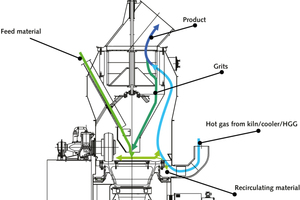

Via a steeply inclined feed chute (Fig. 2) the raw material enters into the mill and falls centrically onto the rotating grinding table. From the centre of the table the material is passed by centrifugal forces into the gap between rollers and grinding table. After being ground the raw material falls over the rim of the grinding table into the nozzle ring. Coarse particles fall through the nozzle ring and are recycled back to the feed chute by a bucket elevator whereas the finer particles follow the gas stream towards the dynamic separator. The separator divides the material into grits and fines. The grits are recycled back to the grinding table to be reground whereas the finer particles pass through the rotor of the separator.

Together with the gas flow the fines leave the mill via the mill exit and are collected in cyclones. The system fan is arranged after the cyclones. The hot gas used for drying comes from the kiln preheater and is mixed with return air before being supplied to the mill.

3 Quadropol2 design features

The latest generation of the Quadropol is designed for drive powers of up to and above 12 MW while assuring high plant availability. In addition, the mill has an extremely maintenance-friendly design concept.

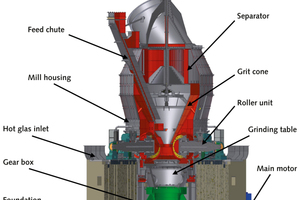

Figure 3 shows the main components of the Quadropol:

the roller units with their integrated hydraulic systems,

the grinding track with exchangeable grinding track liners,

the force-free mill housing with its hot gas inlets and maintenance doors,

the variable speed SEPOL high-efficiency separator and

the drive system, consisting of gear unit and motor.

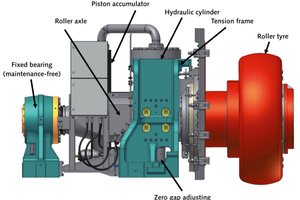

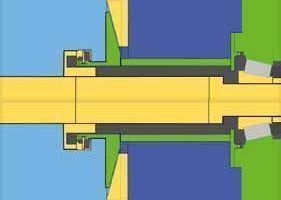

The roller units are shown in Figure 4 in more detail. The bearing units of the Quadropol2 roller units are mounted on concrete foundations. The hydraulic system is incorporated into the tension frame. Every roller unit has only one hydraulic cylinder for the working pressure and one accumulator. This is a simple hydraulic system and therefore very easy to maintain.

The fixed bearing is maintenance-free and requires no additional lubrication. As the bearing units are mounted on separate foundation blocks, the grinding shocks are optimally absorbed, ensuring low-vibration mill operation.

Additionally, the external bearing concept provides considerable maintenance advantages. The mechanical components inside the mill are reduced to a minimum. The patented roller seal located outside the mill can be exchanged without requiring disassembly of the roller. The main components installed outside the mill housing are easily accessible, allowing quick performance of maintenance and repair work. Visual checks are possible at any time - even during mill operation.

As the hydraulic system of each roller unit can be independently controlled, it is possible to change automatically from 4 to 2-roller operation and vice versa. If one roller unit requires maintenance, this and the opposite grinding roller, including sealing frames, are pulled out of the mill housing by hydraulic cylinders. Two extra doors are mounted and the two roller units remaining in the mill continue the grinding process in partial-load operation, which means up to approx. 60 to 65 % of the nominal capacity.

The grinding force for comminuting the feed material is generated hydraulically. By an infinitely variable pressure control the grinding force can be adapted to the current operating conditions of the mill. This facility ensures that the economy of operation remains constant over the entire throughput range. To reduce the mill starting torque, the grinding rollers can be hydraulically lifted before the mill is started and lowered again into the bed of material at a later point in the starting-up process.

As the mill housing is not subjected to any forces there are no housing movements. This is a positive factor for the design of the grinding roller seal between the roller unit and the mill housing (Fig. 5). This contact-free seal is in the form of a ball socket and moves around the fixed bearing pivot point. Practical experience has shown that it is possible to adjust the seal gap to less than 1 mm, minimizing the inleakage of false air even in long-term operation.

The Quadropol2 can be used for raw materials with a very wide range of grindabilities and with moisture contents of up to and exceeding 20 %. Its usefulness is only limited in cases where the material is ultrafine or too abrasive.

4 General arrangement of the grinding plant

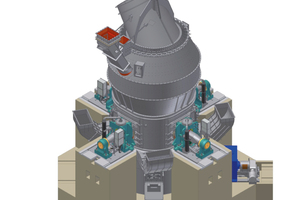

VRMs, likewise the Quadropol, constitute one of the core machines in a cement plant. Each plant has its own requirements in terms of available space, climate or environmental protection. ThyssenKrupp Industrial Solutions has developed several 3D installation models for the Quadropol. E.g. the mill can be installed in a solid concrete building. A crane running on a fixed ring rail serves to move the roller in case of maintenance. Alternatively the solid concrete building can be omitted and the grinding plant then has only a light rain shelter. In this case the roller units of the Quadropol are easily accessible and can be lifted by a mobile crane.

The bucket elevator for the external material circulation can be installed either on zero level or in a pit, closer to the mill.

5 Design data of the first QMR2 in Brasil

For the project for Cia. de Cimento Itambé near Curitiba in Brasil, ThyssenKrupp Industrial Solutions has designed and supplied a QMR2 43/21 with a table diameter of 4.3 m and a roller diameter of 2.1 m. The installed power of the mill motor is 2700 kW. The high-efficiency separator SEPOL QMR-380 has a diameter of 3.8 m and a max. circumferential rotor velocity of 22 m/s. The system fan is designed for a gas flow of 630 000 m3/h at a temperature of 90 °C and a static pressure of 97 mbar.

6 Requirements for the

new raw material grinding plant

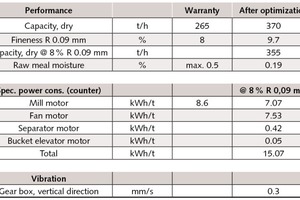

The warranted capacity of the grinding plant with the new QMR2 43/21 was calculated at 265 t/h with a fineness of 8 % residue on the 90 micron screen. If a fineness of 10 % R 0,09 mm was sufficient for the downstream process the warranted capacity had to be raised to 278 t/h and for a fineness of 12 % R 0,09 mm a capacity of 289 t/h had to be achieved.

The warranted specific power consumption for the mill main motor was 8.6 kWh/t at a fineness of 8 % residue on the 90 micron screen. The specific power consumption was referred to a raw material mixture of 92 % limestone, 4 % quartzite, 3.5 % clay and 0.5 % iron ore.

The drying capacity of the mill was stipulated for a fresh feed material with max. 5 % H2O and a residual moisture content in the raw meal of < 0.5 % H2O.

7 Practical experience and operation data

Immediately after commissioning the QMR2 43/21 achieved and even exceeded the warranted capacity considerably (Tab. 1). During an optimization in November 2012 a capacity of 370 t/h at a fineness of 9 % residue on the 90 micron screen (wet screening) was obtained. Of course the mill was equipped with sufficient reserve, but furthermore the performance of the first Quadropol2 for raw material grinding was better than expected. The grindability of the raw material taken during the optimization was the same as determined during the project phase. Nevertheless the specific power consumption for the mill main motor was 13 % below the warranty value referring to the same fineness. The pressure drop over the mill was 73 mbar. The specific power consumption of the system fan was 7.1 kWh/t measured at the counter and referring to a fineness of 8 % R 90 micron.

The load on the bucket elevator for external circulation was 40 % of the mill output at a moderate gas velocity of 36.5 m/s in the nozzle ring. Despite the excellent performance of the mill the vibration level was extremely low with 0.3 mm/s measured at the gear box in vertical direction.

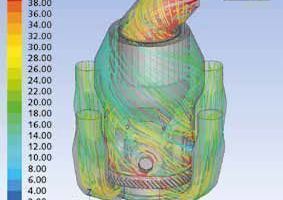

As the shape of rollers and grinding table and the applied grinding force has not been changed compared to the previous version of the Quadropol it can be assumed that an improved dam ring design and optimized gas flow in the mill contribute to the excellent performance of the QMR2. CFD analysis during the design phase have shown that the circumferential nozzle ring with inclined guide vanes causes a swirl in the mill providing a very even gas and material load on the separator (Fig. 6). This again provides for a very good separation efficiency which is proven by well separated grits containing no fines.

Since the start of commissioning in May 2012 the QMR2 at Cimento Itambé is operating trouble-free with continuously good results. The low attention required by the new VRM is very much appreciated by the works personnel.

8 Summary and outlook

With the second generation of the Polysius-Quadropol a vertical mill has been developed which promises high reliability requiring low and easy maintenance. Furthermore the improved operating performance and the more compact design of the roller units have a positive effect with regard to the competitiveness of the QMR2. The device is designed (Fig. 7) for drive powers of up to and above 12 MW providing the possibility to feed even the largest kiln lines with raw meal produced by a single mill.

Meanwhile further vertical roller mills QMR2 have been sold to Indonesia and Germany. These mills were/will commissioned in the second half of 2013 and first half of 2014.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.