Service – the secret of success

With the right maintenance gear units will run reliably for several decades. The oldest one in service is a parallel shaft gearbox which has been in operation for 60 years.

Ready for the next four decades

Finally in 2011 – after approx. 200 000 operating hours – a major overhaul was carried out by two service engineers from FLSmidth MAAG Gear. All obligatory tests regarding the condition of the internal and external parts of the gear were carried out – on site and also in laboratories (Fig. 3). The first as well as the second stage were disassembled completely. The 1st stage was found in good general condition as described in detail further on. Only the bearings had to be replaced due to normal wear. The new gearings were equipped with temperature sensors for more operation data and safety in future. All required spare parts were in stock at the plant.

The 2nd stage was found in very good condition too. Ultrasonic tests were made and all parts could be used again for re-assembling as they were. Input as well as output coupling were checked in detail and were found in acceptable condition. FLSmidth MAAG Gear recommends a service intervention once per year. In addition to the regular maintenance work done by the maintenance team of the plant, this ensures long life and reliable operation. Hence, the cement factory can effectively schedule their shut-down time for the overhaul of the gear, also considering normal fluctuation of the cement demand from the market.

Strict inspections for quality assurance

All the toothed parts such as sun pinions, annulus, planet wheels, planet axles, internal coupling as well as the planet carrier were inspected by external specialists using special testing equipment. Dye penetration tests (PT), fluorescent magnaflux tests (MT) and ultrasonic examinations (UT) were made. PT and MT are generally used to check the surfaces for cracks (e.g. tooth flanks or white metal on bearings). Even micro cracks can be detected by these tests. UT is used to check the parts for invisible damage under the surface (e.g. toothing or planet axles) (Fig. 4).

High quality materials for long service life

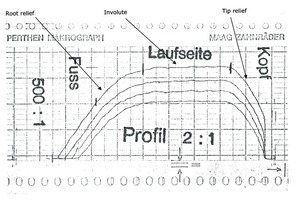

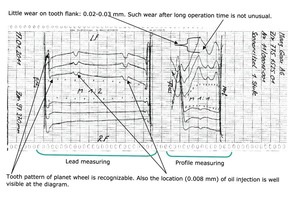

The tooth flanks of the sun pinion (1st stage) were measured in order to make a comparison between the toothing geometry now and the geometry of 37 years ago (Fig. 6). The sun pinion showed a low degree of wear of 0.02 – 0.03 mm which causes no problems at all and will be used for further operation (Fig. 7). The sun pinion toothing is usually the most delicate part as regards wear and tear.

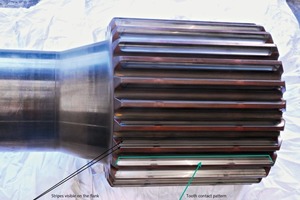

The stripes visible on the teeth of the sun pinion are caused by the starting process of the mill (Fig. 8). During start-up the sun pinion aligns itself between three planet wheels, causing such an effect. The tooth contact pattern of the respective gear covers the whole width, which provides flawless power transmission without any canting. All in all a surprisingly satisfactory result. After the professional overhaul and the positive assessment by the engineering department the gearbox is geared up for the next 37 years and proves the high quality of FLSmidth MAAG Gear products.

Service – what is the objective?

Installation and commissioning: Installing a gear unit is one of the core areas of expertise of FLSmidth MAAG Gear. In addition to technical know-how, the service engineers provide a broad experience from an extremely wide range of projects. They advise customers on site how to achieve a reliable operation and train their employees while commissioning the gear.

Routine servicing: A visual inspection as described below will be performed. After that, the gear is stopped and opened. The service engineer checks the gear in detail and carefully. He performs various measurements and checks the condition of spare and unit parts. The results of his tests provide information about the condition of the gear unit and state of stored spare parts. Any incipient damage is detected at an early stage and remedied. Through regular servicing signs of wear and tear can be observed and upcoming overhauls can be planned properly. This significantly reduces the risk of a breakdown and a loss of production.

Visual inspection: This short inspection is carried out during ongoing operation. The service engineer reads the operating data, measures vibrations and checks the condition of the gear unit. A closer examination is not possible during ongoing operation. The visual inspection provides an indication of a properly running gear. The condition of the spare parts in stock at the cement plant will also be visually inspected.

Overhaul: The customer can actively ensure a long life for the gear system by having it overhauled. The gearbox will be removed and carefully examined on site or in a local workshop. Damaged wear parts are replaced. The customer receives back a renewed and reliable gear unit.

Repair: In the event of damage the service engineers from FLSmidth MAAG Gear arrive very quickly. They conduct the repair on site if possible. If the damage is major the gear unit must be dismantled and repaired in a workshop.

Local service

Our regional Service Centers are located in Australia, Brazil, China, India, the USA, Denmark, Poland and Switzerland. Close to customers over the world (Fig. 9), and always quick to respond.

Training of service engineers

Framework service agreements

Conclusion

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.