100 years of MAAG Gear

FLSmidth MAAG Gear looks back on a lot of challenges that were faced and successfully overcome over the past 100 years. Its success originates from the toothing design which the founder Max Maag developed in 1910 – his basic concept is still used in gear manufacture today.

100 years in perspective

100 years in perspective

Around 1930, Maag-Zahnräder went international and founded subsidiaries in France and Italy. Over the next 50 years, the company developed a number of successful gear measuring and gear grinding machines. After the Second World War the company expanded into the cement and marine industries, producing heavy-duty gear units, turbo gear units and gear pumps.

In the 80s the company board defined a new strategy and expanded into a new market by taking over a company that produced powder castings. The loss-generating machine tool business was closed down and the remaining parts gears and pumps were transferred in the independent companies and Maag Pump Systems. In the 90s it became clear that this strategy was not adding up and Maag Gear was sold in 1997 to FLSmidth. To widen and strengthen the production capabilities Maag bought ABB’s gear manufacturing company in Poland in 2000. And to expand its product range, Maag took over the Italian company Darimec in 2011. Today, FLSmidth MAAG Gear designs, produces and maintains gears, gear units and drive systems for the cement and minerals industries.

MAAG Gear milestones over the past 100 years

1910 – Maag tooth design; still in use today, it provides gear manufacturers with an ideal method of influencing tooth shape to improve load bearing and sliding characteristics.

1913 – Gear grinder guided by diamond tracers for precision-shaped gears for the car industry. This gear grinder was used during the next 70 years.

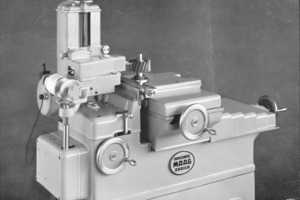

1939 – The PH-60 (Fig. 2) was Maag’s most successful gear-measuring machine. By the time production was phased out in 1981, 1260 machines had been delivered to customers worldwide. Some are still in use today.

1949 – The HSS-360 gear grinder could handle gear diameters up to 3600 mm and workpieces weighing up to 25 tons, making it the largest gear grinder in the world at that time.

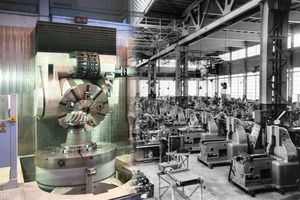

1966 – The design of heavy-duty two-stage planetary gear units – called CPUs – for horizontal mills in the cement industry was an extraordinary pioneering achievement (Fig. 3). CPUs are more reliable than conventional parallel shaft gear units; 265 000 hours and almost 50 years later the first two CPUs installed are still running.

1983 – MAAG delivered its first WPU two-stage gear unit for a vertical roller mill. The largest WPU gear unit weighs 190 tons and transmits 5346 kW.

2007 – MAAG introduced its unique concept of a three-stage bevel planetary gear unit WPV with torque split. The torque split enables approximately 25 % of the power to be guided directly through the planet shafts of the first planetary stage into the output flange. The three-stage concept was the answer to the ever increasing mill sizes. The biggest MAAG WPV weighs 220 tons and transmits almost 8000 kW.

2011 – FLSmidth MAAG Gear launched an entirely new drive concept for vertical mills: MAAG CEM Drive (Central Electric Motor) combines the advantages of proven MAAG gear technology with an ingenious motor concept, all in one common housing.

A new century dawns

Geared up for excellence

FLSmidth MAAG Gear is committed to serving the cement and minerals industries as a Global Technology Centre for engineered drive solutions. To offer clients the highest possible quality at a competitive price, the full range of key gear manufacturing processes must be controlled in-house – from the quenching and tempering of forged steel to tooth cutting by means of a variety of methods, case hardening or nitriding, tooth grinding, verification of tooth geometry on state-of-the-art measuring machines and gearbox assembly and testing. The investment in high-tech DEPO and Klingelnberg gear machining centres goes a long way toward achieving this goal. Klingelnberg GMC 160 and DEPO V3520 were commissioned in autumn 2012.

However these toothed parts are not only used in their own designed products like gear units for horizontal and vertical mills, roller presses or transmission gear units for bucket wheel excavators or belt conveyors. FLSmidth MAAG Gear uses their capabilities and capacities to build gear and bevel sets for crushers, sizers, thickeners and other gear applications in the cement and minerals industry. Planet wheels, sun pinions, bevel wheel shafts, gear rims with internal or external gears and many other toothed components can be manufactured. Depending on their design, application and customer specifications, all of these toothed parts can be manufactured with spur, helical, double helical or other types of gears. The variety of toothed parts as well as the company’s vast expertise make it possible for FLSmidth MAAG Gear to provide customers with complete drive systems from one source.

To manufacture spiral bevel gears, the GMC 160 is incorporated in the KIMoS calculation concept. KIMoS data files can be processed directly in the CNC Control of GMC 160. Special features of GMC 160 include:

Flexible gear cutting of spiral bevel gears and pinions with the cyclo-palloid cutting system

Hard finishing of spiral bevel gears with the Klingelnberg HPG-S skiving process

Digital drive technology with top-notch precision and repeatability

Direct drive hydrostatic workpiece table

High quality gear and tooth surface; described as Q4 acc. to DIN 3965 (after hard cutting)

This milling centre’s processing methods permit the manufacturing of different kinds of bevel gears including straight bevel, skew, palloid, cyclo-palloid and other types. Its manufacturing capabilities are not only limited to bevel gears, rather a variety of external and internal gears can be milled, as well.

These two machines have completed the product range with the result that FLSmidth MAAG Gear is now able to handle all important gear manufacturing processes in-house.

In the past, FLSmidth MAAG Gear has depended on suppliers to provide it with bevel sets and has, on occasion, had waits of up to 18 months when demand was particularly high. Today FLSmidth MAAG Gear is proud to produce its own case-hardened bevel sets with the highest possible quality for this diameter range. The quality of the toothed parts is verified by the state-of-the-art Klingelnberg measuring machine P250 and Klingelnberg gear tester T200. The bevel gear production process has the following steps:

A piece of steel, basically a cylinder with a hole, is ordered.

Steel is hardened through forging. The process employed to achieve the desired level of hardness is similar to that used for Swiss army knives and Japanese swords which are known for their high quality.

During the first step, the steel is turned, then drilled and milled. This lends it the rough cut which already has the shape of a bevel gear (Fig. 6).

It then goes into one of the bevel gear machining centres where the teeth are roughly cut (Fig. 7).

The subsequent case hardening process only hardens the desired parts. Parts intended to retain their original hardness are protected (Fig. 8).

Next the surface is turned and ground.

The last step of the manufacturing process is to make the final tooth cutting of the teeth (Fig. 9).

Now the finished bevel gear is tested and measured by the Klingelnberg T200 and P250 (Fig. 10).

Lastly, the bevel gear is checked and the release form is signed.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.