Newly constructed basement reduces vibrations

University of Thessaloniki, AGET Heracles, Lafarge GroupCalculations using the finite element method (FEM) provided a significant optimization to the basement of cement mills. Operation-related vibrations can be reduced in this way.

Introduction

Introduction

FEM-description of the initial geometry

of the mill installation

Since elastic couplings are used for the torque transfer to the pinions’ axis, which hinder the transfer of torsional or bending vibrations to the pinions, the reducers and the related transmission shafts were not considered in the created model. In the FEM simulation, the torque of the pinion axis was taken into account as the main load.

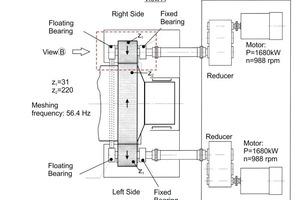

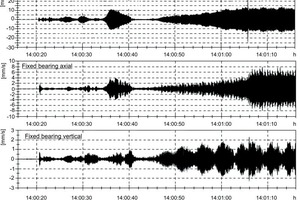

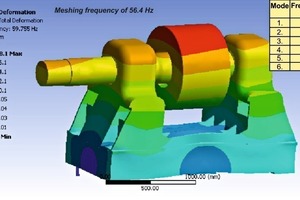

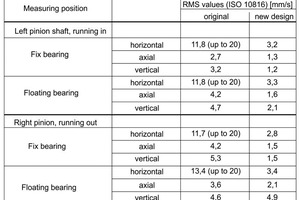

Considering the teeth numbers of pinion and girth gear and the rotational speed of the pinion axis, the meshing frequency of the gear pair was calculated and amounts to 56.4 Hz (Fig. 4). The vibrations in the area of the pinion’s shaft housing were measured in horizontal, axial and vertical directions. A frequency analysis of the time signal of these vibrations revealed a natural frequency of 56.4 Hz which corresponds to the meshing of the pinion-girth gear pair [2, 3].

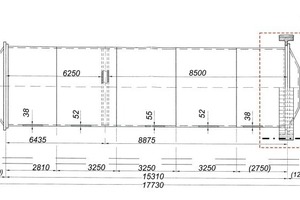

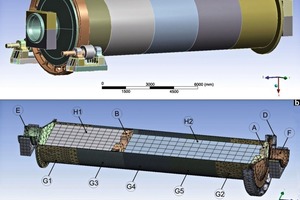

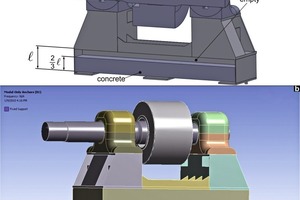

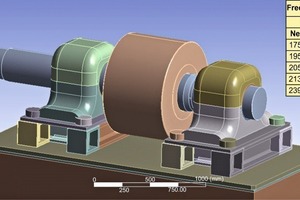

The 3-D model of the mill installation model (Fig. 5a) is created in accordance to the dimensions and the mass distribution in the mill, which is shown in Figure 5b. Geometrical details, with minor contribution to the accuracy of the FE analysis, were omitted to avoid an excessive number of elements in meshing and a consequent increase of the calculation time. The mill was simulated under full load.

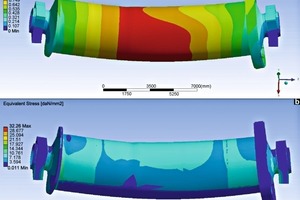

The calculated total deformation and the developed equivalent stresses of the mill under the gravity loads are displayed in Figure 6. The deformations and stresses are low and thus, they cannot be considered as parameters leading to wear or other damages to the pinion girth gear pair. More specifically, the developed maximum mill bending deformation of approximately 1 mm in longitudinal direction can be considered, at the existing overall mill length of ca. 15 m, as negli- gible and the occurred maximum von Mises stress of ca. 3.2 daN/mm2 as low [4].

FEM simulation of the pinion bearings’ housing

basement: Describing its dynamic behaviour

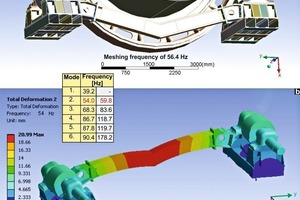

Due to the fact that the excessive wear problems were developed in the region of the pinion’s shaft bearings, the mill manufacturer proposed a solution, often employed in similar installations of other plants. According to this proposal, a V-shaped beam (V-beam) connected the basements of the two pinions. The objective of this construction was to increase the stiffness of the basements for reducing mainly the vibrations level in this area. For investigating the effect of the V-beam application on the system dynamic behaviour, this was modelled considering its original construction drawings.

In Figure 9 the V-beam is presented and also its integration into the whole mill installation. In the same figure the calculated eigenfrequencies of the two pinion bearings’ basements, connected by the V-beam, are demonstrated. The application of the V-beam led to a slight reduction of the critical eigenfrequency of the pinions shaft housing without the V-beam connection from 59.8 Hz to 54 Hz (see table in Fig. 9). Moreover, it introduced a new eigenfrequency, the first one, at 39.2 Hz. This frequency is not considered as critical, since it lies more than 30 % far from the pinion-girth gear meshing frequency of 56.4 Hz. However, because of the small distance of the second eigenfrequency of 54 Hz to the pinion-girth gear meshing frequency (< 6 %), the second eigenfrequency is now considered as critical for the appearance of resonance vibrations.

The eigenform at 54 Hz is also monitored in Figure 9. The pinions’ shaft housing and its basement conduct a rotational vibration around an axis, parallel to the pinion shaft, as was the case during mill operation without the V-beam. Thus, the application of the V‑beam is not recommended, since the resonance vibrations at the pinion-girth gear meshing frequency cannot be avoided.

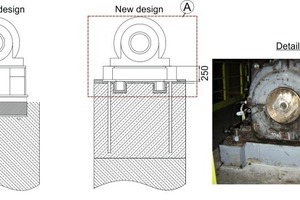

Redesign of the housing basement

for the reduction of vibrations

Conclusions

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.