Model-based kiln control for green cement production

After the development of the models and the entire automation system was complete, the application of the model predictive control was successfully proved in an initial connection trial at the reference plant CEMEX OstZement in Rüdersdorf.

1 Introduction

In this article, the authors describe a tool...

1 Introduction

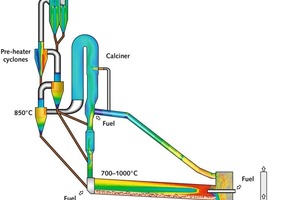

In this article, the authors describe a tool chain generated in the context of the research project MoProOpt (model-based process optimization of secondary fuel-fired cement production plants). The tool chain extends from a detailed model of the cement production process to the development of a model-based control system.

The starting point of the work was developing a complex numerical flow simulation of the entire thermal clinker firing process, taking the use of secondary fuels into particular consideration. This was accomplished by the aixprocess company in Aachen in close cooperation with the operator of the reference plant CEMEX OstZement in Rüdersdorf. The CFD model obtained in this way can be easily adapted for use with other plants, in terms of both plant geometry and special features in the combustion behavior of the secondary fuels used. The current CFD model, which already features a high level of development, offers plant operators an excellent starting point for investigating and solving existing problems in the plant.

Because a dynamic simulation of the complex CFD model requires a great deal of calculation time, such a model cannot be used directly for real time control. The challenge connected with developing the model supported control system is transferring the adapted CFD model into a model of the thermal clinker firing process that is both sufficiently accurate and capable of real time performance. To do this, in an intermediate step the model complexity is reduced to a simplified cell model.

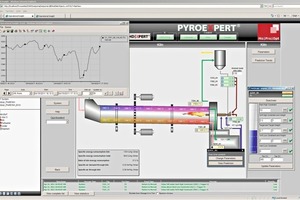

The control system developed by KHD Humboldt Wedag and the Institute of Automatic Control (IRT) in Aachen was recently tested in an initial connection trial at the reference plant CEMEX OstZement in Rüdersdorf. The test was successful.

2 Current situation in cement production process control

For this reason, due to the diversity in the substances used and the process reactions, the understanding of which has previously been insufficient, all over the world everyday operations in cement plants are carried out in such a way that there is a large gap between the actual operations and the optimum process limits in order to ensure safety.

By combining data-driven models (neural networks) with knowledge-based approaches (fuzzy rules) and model supported predictive control approaches (MPC), most of the automation products available today for cement manufacture attempt to compensate for the absence of detailed physically motivated models capable of real time performance and the lack of sufficiently available measurement information [1].

Existing control systems for the cement industry combine MPC systems with very simplified physically based models, which also concentrate only on mapping the parts of the cement manufacturing process (e.g. the calciner) [2].

With all of these approaches, however, significant process information remains hidden because these approaches cannot record or simulate it.

3 Model of the thermal clinker firing process

Taking all air and fuel flows at the burner into consideration, the CFD simulations provide insight into the combustion behavior of the various fuels, which is primarily limited by substance transport. Figure 2 shows an approximate illustration of the flame contour of a coal flame for a multi-channel burner.

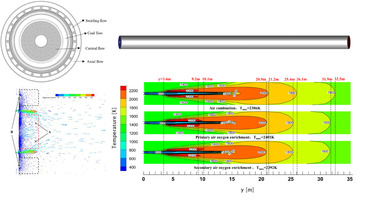

A significant advantage of the simulation technol-ogy is that it can extract information from the flame that cannot be accessed using measuring technology (Fig. 3). In this way, in a burner in which several types of fuel are used simultaneously, the contributions of the individual fuels to the flame synthesis can be worked out.

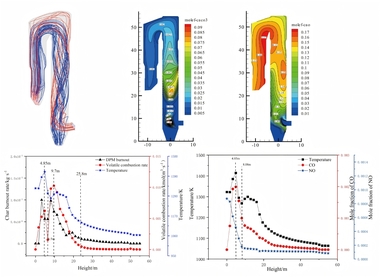

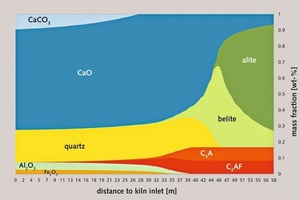

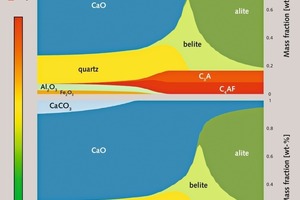

The combination of combustion and material bed enables a prediction of the product formation. It also demonstrates the progression of the clinker phase composition along the rotary kiln as generated in the simulation in the form of a typical phase diagram for the cement industry (Fig. 4). In this way, the effects of a flame of varying heat on clinker formation can be reproduced in the simulation (Fig. 5).

4 Model reduction

The commercial software package Dymola was used to develop a reduced 1D-model [4]. The gas phase was provided with a chemical reaction model that describes the fuel reactions based on a general Arrhenius approach. The parameters of the reaction kinetics were used to lead the ideal 1D-model (Fig. 7) toward the results of the CFD model. The pseudo reaction kinetics generated in this way take into consideration both the temperature dependency and the influence of local flow and mixture relationships that arise from the specific plant set up.

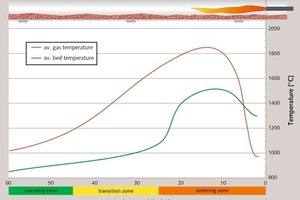

The good agreement between the 3D-CFD-model and the 1D-model based on the temperature profile in the gas and the wall lining (insulation) of the rotary kiln is shown as an example in Figure 8. The non-linear model can be further transformed into a linear model to reduce the computation time for the model-based predictive control approach. After approximations are made in the complex non-linear model for selected operating points and after the resulting linear model is reduced (truncated balanced realization), a compact linear state space model is generated that can be used for the MPC.

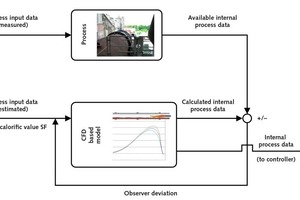

5 Observer-based model predictive controller

6 Testing the control on a reference plant

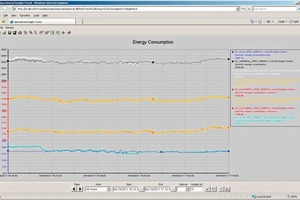

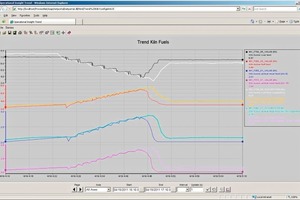

The system increased the secondary fuel rate during the connection phase in accordance with the quality function stored in the system without negatively affecting clinker production. The goal of this quality function is to provide short term control with the long term maximum application of secondary fuel. The overall energy yield in the kiln during this period remained constant.

In addition, due to the predictions of the internal state variables the system provided the operating personnel with valuable information from the process independent of the control, which had not previously been available (see Fig. 14).

7 Outlook – Changing over to “green cement

production”

For this reason, protecting the climate is a stated goal of the cement industry, which is contributing to this global effort by committing to reduce by half the CO2 emissions generated by cement production by 2050. For the cement industry, this means changing over to “green cement production” and reducing CO2 emissions by about 18 % by 2050 as compared with today‘s emissions. In addition to implementing measures for increasing thermal efficiency, operators of cement plants must plan to increase their use of secondary fuels.

From an environmental perspective, secondary fuels are more suitable for use in the cement industry than in other industry sectors because secondary fuels can be almost completely integrated into the process in terms of both their substance and thermal value. In this way, on one hand the energetic components of the secondary fuels can help replace fossil fuels and on the other, their anorganic components such as ash can be completely integrated into the clinker product, thus saving landfill space.

In 2006 the worldwide percentage of secondary fuels used was around 10 %, 7 % of which consisted of waste from industrial products and 3 % of biomass. 90 % of the fuels continued to come from conventional fossil energy sources (primarily coal).

If it is taken into consideration that in European countries, a substitution rate of over 50 % has been achieved and that in some cement plants, such as the reference plant of CEMEX OstZement in Rüdersdorf even greater average substitution rates are possible, it becomes clear that the worldwide cement industry can contribute significantly to global CO2 reduction.

Due to the increasing complexity of process control when using secondary fuels and the necessity of operating conditions that optimize energy savings, the automation concept developed here helps to simplify process control even when using secondary fuels, thus providing a great number of cement plant operators with the opportunity to contribute to CO2 reduction.

8 Conclusions

After the development of the models and the entire automation system was complete, the application of the model predictive control was successfully proved in an initial connection trial at the reference plant CEMEX OstZement in Rüdersdorf. These trials have demonstrated that the changeover to and acceptance of the control of the respective actuators can be implemented safely. In addition, the functionality of the measures for securing the operational state of the plant has also been demonstrated.

Further trial runs planned for the near future should be used to optimize the control parameters and integrate further secondary conditions into the control concept on the way to stable and reliable operation over the long term.

The principle of model predictive control introduced here was developed and tested using the cement production process as an example. However, the concept can be transferred to other high temperature processes with similar problems with respect to process automation.

Acknowledgments

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

![7 1D balance element for the kiln [4]](https://www.zkg-online.info/imgs/tok_5e3ff595d03061ad90386c76f7531afa/w300_h200_x400_y214_101530191_715be501ff.jpg)

![8 Comparison of the temperatures of the 1D-model (MODELICA) and the CFD-model [4]](https://www.zkg-online.info/imgs/tok_cfa70f19461f33fa9d66c37f57b96015/w300_h200_x400_y311_101530182_4eb2bedd45.jpg)