High-tech for “dusty” energy

With the sensible handing of resources, even those sources of raw materials which are not in the spotlight, such as lignite or similar fluidizable dust materials, become attractive. A plant manufacturer who has found a way of burning these energy sources economically using special technology has set up south of Munich. End-to-end automation based on the model of Totally Integrated Automation (TIA) plays a crucial role in the dosing and combustion of dust.

Lignite is part of the energy mix

In addition to regenerative energy, which is attracting particular attention at the present time, there...

With the sensible handing of resources, even those sources of raw materials which are not in the spotlight, such as lignite or similar fluidizable dust materials, become attractive. A plant manufacturer who has found a way of burning these energy sources economically using special technology has set up south of Munich. End-to-end automation based on the model of Totally Integrated Automation (TIA) plays a crucial role in the dosing and combustion of dust.

Lignite is part of the energy mix

In addition to regenerative energy, which is attracting particular attention at the present time, there is a series of other alternatives which can also achieve good results with the right technology. Today, energy use by means of combustion is a key issue worldwide. For example, due to its comparatively simple breakdown, lignite continues to be a part of the energy mix. This is especially true where the combustion plants are economical and work with a high degree of efficiency. “Here, our dosing systems and hot gas generators prove to be an interesting solution”, asserts Dipl.-Ing. Peter Schöfmann, head of the electrotechnology department at the plant manufacturer Carbotechnik Energiesysteme GmbH in Geretsried, to the south of Munich. This has the result that boiler systems as designed by Carbotechnik achieve a degree of efficiency of more than 92 %, according to the company.

By means of patented developments, a homogenous combustion was devised so that plants with a high degree of efficiency could be built. A significant advantage as compared to competitors is that a fast change-over from fluidizable energy sources in dust form and gaseous energy sources is possible in the Carbotechnik plants.

Dosing systems with an accuracy of more

than three percent

The homogenous mixing of dust and air is crucial for the energy-efficient combustion of energy sources in dust form. Uniform combustion in accordance with the performance requirement, as is known from gas flames, also plays an important role here. For this purpose, the Bavarian company constructs the appropriate dosing systems, which have a dosing accuracy of more than ± 3 %.

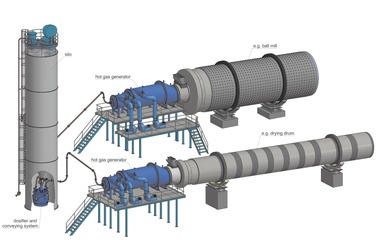

The dosing equipment (Fig. 1) consists of a cylindrical container which is pressure shock resistant up to 10 bar (for pulverized fuels). It has a flow floor at the bottom and is filled with the product to about two thirds of its capacity. If air is pushed through the flow floor from below at low speed by means of a fluidizing fan, the product fluidizes. This means that it expands by approximately one third and takes on liquid-like properties. By means of one or more horizontally rotating breaker plates, the fluidized dust is conducted in feed lines to the subordinate combustion systems.

Distributed I/O for autonomous subsystems

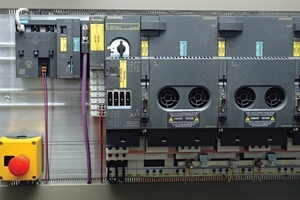

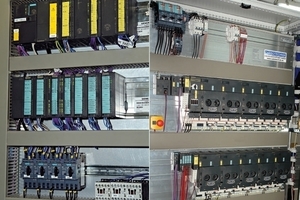

Because these dosing systems are also supplied to customers as simple subsystems, autonomous operation proves to be extremely practical. “For this reason, we use the Siemens Simatic ET 200S distributed I/O, which can be adapted flexibly to every requirement”, explains Josef Hundegger from the electrotechnology department at Carbotechnik. If the dosing system is supplied as a subsystem (Bild 2), the ET 200S is equipped with an IM 151 head module. This CPU processes all signals and communicates with the higher-level plant controller via a Profibus module which also fits into the system.

In fact, practically any I/O modules, motor starters and frequency converters can be combined with each other. Even the safety technology and standard automation can be processed on one and the same unit. While Profibus is still used frequently in the machine environment, Carbotechnik increasingly relies on Profinet. To this end, an appropriate module which makes several PN ports available can be connected to the Simatic ET 200S distributed I/O (Fig. 3). This means that the dosing systems can be easily integrated into plants and are prepared for remote service at the same time.

Visualization with archive and remote access

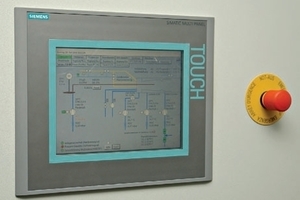

To improve both the dosing and the combustion technology it is important to be able to monitor and archive the process data at all times. For this reason in every system – wheather it is a dosing unit or a hot gas generator – a Siemens MP 277 Touch Panel is implemented for visualization. The great advantage is that these devices support an archiving function with which important values can be stored – not to mention the fact that they have high resolution and allow a color display.

In addition, the Touch Panels support the so-called Smart Service, that is, remote access via an IP address and a VPN connection. By means of remote maintenance, the company can have password-protected access to the panels at any time and does not necessarily have to intervene in the control of the plant to view the process parameters.

Comprehensive visualization options

Parameter assignment for Carbotechnik systems – either dosing systems as standalone deliveries or entire systems for heat generation – can be carried out by the process engineer almost completely via the visualization. This means that operators do not need any control engineers to use or adapt the systems.

With the visualization software WinCC and WinCC flexible, it is easy to draw plant pictures, show or change parameters, display errors, collect faults and archive values. In the software, the programmer can define, for example, which parameters should be archived – and from which threshold values or for how long these should be recorded. The archive can be backed up on a commercially available data stick which is inserted into the USB port on the MP 277. With the size of the flash memories available today, every plant can be equipped with a really huge archive in an easy and cost-effective way.

High-tech leads to energy-efficient solutions

Particularly for the hot gas generators, the sophisticated process technology plays a crucial role in combustion of the dust/air mixture from the dosing system with as little residue as possible. This type of pulse burner from Carbotechnik, for example, is characterized by the fact that a circulating movement takes place with the combustion air, mixed air and cool air, which results in a continuous, clean and self-sustaining combustion with correspondingly low residue levels. In this way, a permanent supporting flame is not necessary and fuel costs are kept low.

In addition, the external walls remain comparatively cool, which means that a refractory lining with fireclay is not needed. This not only saves on investment costs, but also has a very positive effect on the operation of the plants, because pre-heating and cooling down times can be eliminated. This also means that the burners can be heated to the highest level within a very short time.

Safety technology included

To ensure that all boundary conditions are complied with, the automation specialist uses the Siemens Simatic S7-315 F 2DP/PN controller (Fig. 4a). For him, the memory capacity rather than the high computing speed of the controller is of importance. It is also available – like the ET 200S – with a Profinet connection and a fail-safe CPU.

In the dosing system, a safe stop must be guaranteed for the frequency-controlled dosing plate during maintenance work, for example. To this end, the relevant ET 200S frequency convertor (Fig. 4b) – or, alternatively, the Sinamics G120 – is equipped with the appropriate safety functionality. However, the level probe and the motor starter for the mixer above the flow floor also require safety-oriented monitoring.

In the hot gas generator, on the other hand, everything involved in the combustion requires safety-oriented monitoring. This includes the analog measurement of the airflow, as well as the pressure switch and the gas valves for the ignition – no problem, with the Simatic S7-315 F.

TIA means that everything fits

The value of coordinated automation solutions is made clear on the basis of the example of Carbotechnik Energiesysteme GmbH in Geretsried, south of Munich. With both the dosing equipment for fluidizable dust and the burners for drying plants which the company manufactures, the automation is primarily based on Siemens systems.

Peter Schöfmann emphasizes: “The great advantage of this is that the individual components are very powerful and can easily be combined with one another.” For communication, he favors Profinet. Even the safety functions can be implemented on the same platform as the standard automation. The automation specialist is convinced of the benefits and the future of Totally Integrated Automation (TIA).

www.automation.siemens.com

www.carbotechnik.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.