Positive operating experience after separator replacement

In July 2010, Phoenix Zement in Beckum optimized a grinding plant by changing the separator (see report in ZKG INTERNATIONAL 09/2010, pp. 20-23). The background to this investment by Phoenix was the need to produce high-performance cements in an energy-efficient manner in order to remain competitive and even strengthen their position. With the old system it was either impossible to produce the high-performance cements, or it could only be done at low throughput rates and high energy costs. The experience from more than one year of operation and the results of production analyses prove that the...

In July 2010, Phoenix Zement in Beckum optimized a grinding plant by changing the separator (see report in ZKG INTERNATIONAL 09/2010, pp. 20-23). The background to this investment by Phoenix was the need to produce high-performance cements in an energy-efficient manner in order to remain competitive and even strengthen their position. With the old system it was either impossible to produce the high-performance cements, or it could only be done at low throughput rates and high energy costs. The experience from more than one year of operation and the results of production analyses prove that the optimization was well worth while.

1 Task

There are more than enough reasons to consider modernizing a plant. Surplus standard cement capacity with the associated cost pressure, demand for quality cements with high strength values and the increasing trend to substitute clinker with alternative raw materials such as blast furnace slag and limestone are often important aspects defining the demand for efficient and cost-effective production.

The Phoenix cement factory in Beckum produces various cements of types CEM I to CEM III, as well as special cements and special building materials. The factory is equipped with two closed-circuit grinding plants, both of which are supplied with primary ground clinker from a horizontal impact crusher (HIC) mixed with gypsum and other additives. The two mills are the same size but were installed and put into operation at different points in time. The older unit, cement mill 1 (CM 1), was equipped with two Heyd separators (dynamic separators of the first generation), while the cement mill 3 (CM 3) installed later was equipped with a closed-circuit cyclone separator (a dynamic separator of the second generation).

Increasing competitive pressure and high energy costs prompted the owners of the Phoenix cement factory to investigate which plant components could be optimized by means of a modernization project.

2 Modernization project

It quickly became clear that special consideration should be given to the separator circuit of cement mill 1, because it decisively influenced the ultimate quality of the cement produced with regard to fineness and particle size range. It was found that the old Heyd separators were the weak point in the plant operation because of their design and operating principle which resulted in poor separation efficiency, poor sharpness of separation and insufficient product fineness setting range.

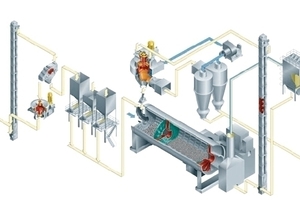

For this reason, it was decided that the separator system had to be optimized (Fig. 1).

The modernization concept involved replacing the existing two Heyd separators with a new high-efficiency separator of the latest third generation. The plant investigations performed otherwise revealed no significant weak points that could be responsible for a poor grinding system performance. For this reason, no modifications of other system components were carried out. This also ensured that later evaluation of the operating results would only show the effect of the separator replacement. The selected replacement unit was a QDK 29-NZ high-efficiency separator from Christian Pfeiffer.

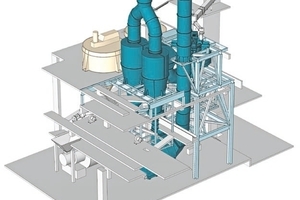

The layout concept drawn up was convincing. It enabled the new machines to be incorporated into the existing building in such a way that the old Heyd separators could remain in operation right up to the end (Fig. 2). With an actual changeover time of only three days, it was possible to implement a tight time schedule. The hot phase of the main installation work took six weeks, but was carried out without interrupting the grinding system operation. The separator circuit is equipped with cyclones for collecting the finished product. The separator and the cyclones are so incorporated into the system that the existing conveying equipment for separator feed, finished product and reject could continue in use. Thanks to good work preparation, the commissioning was absolutely trouble-free. Right from the beginning, the new components showed an extremely high degree of reliability.

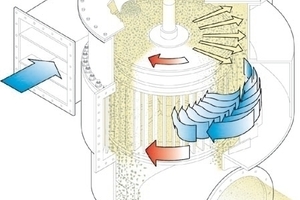

3 Functional principle of the cross-flow

rotary cage separator

The new separator is a 3rd-generation QDK 29-NZ unit. The material to be separated is fed onto the distributing plate via two diametrically arranged spouts (Fig. 3). The distributing plate rotates at high speed, throwing the material over the outer rim and against the side walls of the separator. The impact disintegrates any clumps and the dispersed material then falls into the separating area. While the material is in free fall, the separation process takes place: an air stream introduced into the separating area via the inlet spiral is diverted by guide vanes tangentially to the cage and into the falling stream of material. This cross flow of air carries the smaller and lighter particles of material through the blades of the rotor and into the rotating separator cage. Entrained in the air stream, they are transported to the cyclones and collected as fine product. In contrast, the coarse particles are not entrained in the air stream and fall into the grit outlet cone and are then returned to the mill. The separator achieves an excellent sharpness of separation and separation efficiency (recovery of fines) thanks to low bypass rates. Due to the variable-speed separator cage drive, the highest cement fineness grades can be achieved and sealing air prevents oversize particles from infiltrating into the finished product.

4 Results

Prior to and subsequent to the conversion, Phoenix Zement has produced the following cement grades according to DIN EN 197-1 in cement mill 1.

Portland Cement CEM I:

CEM I 32.5 R and CEM I 42.5 R

Portland Composite Cement CEM II:

CEM II/A-LL 32.5 R

Over and above that, the company is now able to meet the market requirement for a highest-grade cement CEM I 52.5 R, which could not be produced with the old separators of the first generation. It was only the replacement of the old separators that enabled this product to be successfully taken into the company‘s product range.

After the separator system had been converted, the cement grades were initially set to the same product fineness as before the separator replacement. The aim was to maintain the quality parameters and assure safe production of saleable products. The set parameters were the main cement quality requirements such as fineness and water demand.

In this initial phase, priority was given to product comparability instead of the most efficient possible mode of operation, because Phoenix wanted to ensure that customers continued to receive the expected products. This meant that production continued without any fluctuations, but the production capacity of the new equipment was not being fully exploited.

Around six weeks after the modification had been concluded and the system parameters had been set, an inspection of the overall system took place, including axial metre sampling, examination of the mill, appraisal of the separator etc. Subsequent to that inspection the air flow rates were optimized, so that the production parameters were precisely adjusted and optimum values were achieved for the residues and finenesses. In February and March 2011 a second inspection was carried out, with a re-audit, determination of the separator efficiency rates and a Tromp curve analysis.

Fig. 4 shows the development of production output over time (red line) during the individual operational phases, taking Portland composite cement as an example.

The production output in the quarter year preceding the commissioning, i.e. with the old system configuration, was taken as the starting basis for quantification of the optimization measure (standardized to 100 %).

Immediately after the separator replacement it was already possible to detect an increase in production output. This resulted from the significantly better fine material output of the high-efficiency separator. With the previous separator, a large proportion of already sufficiently fine particles was not separated out but returned to the mill and caused overgrinding. The amount of grinding work expended on already fine particles hardly improved the product characteristics and was no longer available for grinding coarse particles. The new high-efficiency separator brings considerably more fine particles into the fine product and therefore avoids this wasteful overgrinding effect.

The second effect is the separation sharpness achieved by the separator. With a highly selective separator, a far greater amount of particles with a fineness above the set cut size are separated out from the product. As a consequence, the same specific surface fineness according to Blaine results in a lower amount of residue on the 45, 63 and 90 µm screens. Coarse particles in the product have a negative effect on the strength development of the cement.

4.1 Case study 1: Portland composite cement

CEM II/A-LL 32.5 R

This relationship between the separator‘s selectivity and the strength development and residue values is most clearly shown by the manufacturing of CEM II/A-LL 32.5 R, which has a 13 % content of limestone.

After replacement of the separator, the same specific surface acc. to Blaine of 4100 cm²/g was initially retained (Tab. 1). This resulted in a jump from 24 N/mm² to 31 N/mm² in strength development after two days and from 48 N/mm²/g to 59 N/mm² in strength development after 28 days.

Fig. 5 clearly demonstrates that there is a direct relationship between the strength development and the specific surface of the cement. The finer the product, the higher the strength development, independent of the separator used. However, the positive influence of the high-efficiency separator can be clearly seen in the higher strength values within any fineness category.

In contrast, the results of the Heyd separator show that the ultimate strength (after 28 days) was only insignificantly affected by an increase in Blaine value. The reason for this was that the 1st generation separator always let a certain amount of oversize infiltrate into the finished product, which had a negative effect on the ultimate strength. To illustrate this relationship, Fig. 6 shows the residue value on the 63 µm screen plotted against the specific surface. In the case of the Heyd separator, the residue value of 6.5–8 % is quite high and only changes slightly over the analyzed range of 3800–4200 cm²/g. However the high-efficiency separator QDK 29-NZ achieves a significantly lower residue value of 63 µm and even at specific surfaces of 3450 cm²/g the value is below 4.5 %.

Based on these findings, Phoenix was able to progressively reduce the product fineness to again obtain the original quality values such as strength. The two cement grades prior to conversion (4100 cm²/g) and at present (3450 cm²/g) are of identical quality. The improved particle size distribution of the product resulting from the effect of the separator enables the same product characteristics to be achieved with a lower specific surface. Thanks to the production of a coarser cement, there is a lower power requirement per tonne of product. This power saving can be employed as additional grinding capacity. Even with the unchanged product fineness an increase in output is achieved, mainly due to the avoidance of overgrinding.

4.2 Case study 2: Portland cements CEM I

During the commissioning and optimization phase, samples were taken from the separator at different finenesses of a CEM I cement. These samples served as a basis for preparing Tromp curves showing the behaviour of the separator over a range of different product finenesses. Plant-specific operating data such as total feed rate, ball charge, mill ventilation etc. were left unchanged during these measurements.

Fig. 7 shows four Tromp curves for product finenesses ranging from 3000–5000 cm²/g, which covers the entire range of cement finenesses that a cement producer demands from a separator. A comparison of the Tromp curves CEM I 32.5 R (light blue) and CEM I 42.5 R (red) essentially just shows a parallel shift. The bypass value τ is practically identical in both cases (Tab. 2).

In the case of CEM I 32.5 R (light blue curve), the sharpness of separation is somewhat poorer than it is in the other cements, due to the desired coarser target fineness. As the product fineness increases further, the bypass value τ increases slightly. In the case of the finest product with 5005 cm²/g, the Tromp curve falls steeply in the particle size range 2–10 µm. As a rule, the cause of this is the adhesive force between the finest particles or between the finest particles and larger particles. These adhesive forces have a negative effect on the separator efficiency. However, it can be generally said that Tromp curves with bypass values of < 10 % indicate that the separator is functioning very efficiently.

5 Conclusions

In those areas where improvements had been planned they were, in fact, achieved. After the optimization phase, specific energy savings of around 10 % were achieved for CEM I 42.5 R and 20 % for CEM II/A-LL 32.5 R. Furthermore, the modification enabled Phoenix to produce the new cement grade CEM I 52.5 R for the first time and it has meanwhile been successfully established in their range of products.

In a little less than 1.5 years of operation there have been no significant malfunctions, which is expressed in the hitherto achieved plant availability of above 99 %. Phoenix Zementwerke and Christian Pfeiffer Maschinenfabrik have succeeded in developing a system configuration which allowed installation of the new separator parallel to the continuing operation of the old equipment. The stoppage time was therefore kept very short.

Together, we also developed a long-term commissioning and optimization plan that eliminated quality fluctuations at the commencement of commissioning and ensured a safe transition to the best possible operational settings. Christian Pfeiffer also attended to the process technological steps involved in introducing the new cement grade.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.