Ceops –

Expert analyzing system for mill operators

Cemtec as a highly reputed heavy-duty equipment manufacturer and plant design specialist continuously strives to support its customers in their daily production business even after successful commissioning. The process expertise demonstrated in the design of the mills, separators and industrial installations is extended with the development of the Ceops, a tool assisting plant operators in improving product quality and lowering operational costs throughout the lifetime of the plant.

Cement producers, especially the operators of cement grinding systems, are dependent on many factors and variables, e.g. chemical composition of clinker and additives, moisture of feed materials, particle size of feed materials and of the finished product. Furthermore, the cement grinding process requires a high energy input and the cost of electricity has a major influence on the production costs.

Therefore, an efficient mill operation requires continuous adjustment to the varying operating conditions. Measuring and controlling the particle size distribution of the finished product – cement –...

Cement producers, especially the operators of cement grinding systems, are dependent on many factors and variables, e.g. chemical composition of clinker and additives, moisture of feed materials, particle size of feed materials and of the finished product. Furthermore, the cement grinding process requires a high energy input and the cost of electricity has a major influence on the production costs.

Therefore, an efficient mill operation requires continuous adjustment to the varying operating conditions. Measuring and controlling the particle size distribution of the finished product – cement – is important for achieving the desired product performance at the lowest production cost possible.

The particle size distribution and specific surface have a large influence on cement performance. A historic technique for measuring the specific surface is the Blaine test. The Blaine test, however, has several disadvantages, e.g.:

the Blaine value is just an indication of specific surface

cements with the same Blaine value may show different performance characteristics

the accuracy of Blaine measurements is lower for finer cements

real-time measurements are not possible and operation adjustments are lagging 60 to 120 minutes behind, depending on sampling frequency

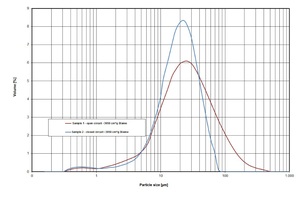

One of the most important characteristics of an analytical technique is its ability to differentiate between samples that perform differently within an application. However, two cement samples with an identical Blaine value can show different particle size distributions when measured by laser diffraction.

In the example shown in Figure 1, sample 2 contains more fines than sample 1, but also coarser material, resulting in the fact that both samples have the same specific surface. This illustrates why two samples with quite different particle size distributions can have the same Blaine value, but different cement properties.

The hydration speed of cement particles is a function of the particle size distribution and determines the strength of the set cement. In general, finer particles hydrate more quickly, giving greater strength, and within certain limits, finer cement is better cement.

Very fine cement particles in the range of 2–3 µm may cause exothermic cracking. On the other hand, particles over 50 µm may not hydrate, compromising product strength. Sample 1 contains fewer fine and coarse particles and consequently has superior cement properties, even though the Blaine value is equal to that of sample 2.

In daily cement grinding operation, a sample is taken every one to two hours and sometime later, the operator receives the fineness results measured in the laboratory and can take corrective action. Reducing the particle size of the cement too much, within limits, tends to simply improve its quality but requires significantly more energy; this so called “overgrinding” is typically the result of a late and poor grinding system control.

To overcome this constraint, Cemtec has developed the Ceops online particle sizer as a technological upgrade package especially for cement grinding circuits. The system can also be installed in other dry or wet grinding systems.

The Ceops is equipped with an online laser analysis providing real-time particle size distribution, enabling the operator to identify and evaluate changing operating conditions and to take the necessary corrective actions or make adjustments in time.

Thus, operation efficiency is improved and production costs are reduced by operating the system at the desired fineness setpoint, which is measured in real time, and overgrinding is reduced.

Further measureable advantages of the Ceops are:

stable cement quality

decreased specific energy consumption

faster automatic adjustment in case of cement quality change

increased production capacity

decreased mill operator activities

These improvements result in increased financial performance and usually, the return of investment for the Ceops system is around 6 to 12 months.

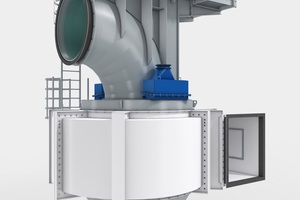

The Ceops system is a custom-made solution entirely engineered, developed and manufactured in Europe. The modular approach allows for a quick and easy adaptation to any existing grinding circuit, ball mill system or VRM system alike.

The Ceops system basically consists of:

automatic sampling device

Ceops measuring unit with a highly developed particle size characterization laser

Ceops control system

interface to existing plant operation system

KMC high performance control system (optional) with mill level measurement

recipe management (optional)

The optional KMC high-performance controller and the recipe management enable a fully automatic grinding system operation.

Usually, the automatic sampling device is installed in the discharge chute of the product separation equipment, either a bag filter or a cyclone, to obtain a representative sample of the product. It may be located in an airslide or even in a product-loaded air stream, as well. The installation of the sampling device takes only half a shift; pneumatic transport from the sampler to the Ceops unit via a hose with a quick connection coupling is foreseen. Details of this sampling device are shown in Figure 2.

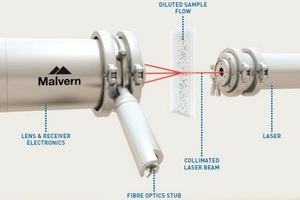

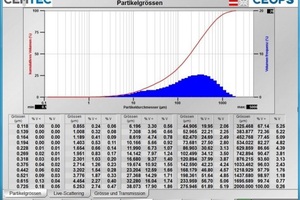

The particle size laser is installed in the Ceops cabinet. The particle measurement range is from 0.1 μm to 1500 μm. Four measurements of the collected sample are taken per second.

The design of the Ceops connects up to three sampling points. The samples are taken one after the other, transported to the Ceops and then measured in series. The schematic setup and typical measurement results are depicted in Figure 3.The distance between the sampler and the Ceops control system can be up to 50 m. Therefore, the Ceops can be connected to up to three grinding systems.

If the distance between the sampling points exceeds these 50 m, the Ceops cabinet can be equipped with rollers for an easy transport between the sampling points as shown in Figure 4. The disconnection and reconnection of the pneumatic transport hose to the sampling device take less than 10 minutes.

Interfaces to all major control system networks are provided. Therefore, the Ceops system can be integrated in the existing operator control system. Cemtec also offers the KMC high-performance control system for boosting efficiency even more.

Summarizing, the Ceops online particle sizer’s main benefits in a nutshell:

increase in production

reduction of specific energy costs

high and consistent product quality

reduction of plant start time and time for product changes

reduction of maintenance costs

three sampling points – one Ceops

distance between sampling points and Ceops max. 50 m

disconnection – connection to sample points < 10 minutes

4 complete sample measurements per second

recommended spares: laser protection glass only

delivery time 10 weeks or less

ROI in 12 months or less

Cemtec has one system available for leasing with a purchase option after the testing period, so that customers can experience the positive effects of Ceops in their plants.

//www.cemtec.at" target="_blank" >www.cemtec.at:www.cemtec.at

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.