Wet preparation at Schaefer Kalk

Schaefer Kalk, with registered offices in Diez an der Lahn, is a family-managed lime industry company with a long tradition and plants located in Germany, Europe and around the globe. Ever since the company’s foundation in 1860, innovative thinking, high quality standards and diversification into lime products for numerous industries have made Schaefer Kalk a byword for burned and unburned lime products, precipitated calcium carbonates (PCC) and premixed dry mortars. Its range of products extends from limestones and calcium oxide and calcium hydroxide, up to and including ready-for-use milk of...

Schaefer Kalk, with registered offices in Diez an der Lahn, is a family-managed lime industry company with a long tradition and plants located in Germany, Europe and around the globe. Ever since the company’s foundation in 1860, innovative thinking, high quality standards and diversification into lime products for numerous industries have made Schaefer Kalk a byword for burned and unburned lime products, precipitated calcium carbonates (PCC) and premixed dry mortars. Its range of products extends from limestones and calcium oxide and calcium hydroxide, up to and including ready-for-use milk of lime and fillers/extenders, plus pigments for special applications.

This Rhineland-Palatinate company regularly invests in production technology, in order to meet the high quality demands made on Schaefer Kalk products. One example is the preparation facility for limestones at the Hahnstätten plant, also located in Rhine-Lahn county.

This system comprises a crusher installation, in which the limestones are crushed and screened. Quality is monitored by means of camera diagnosis and rejects separated out pneumatically. After wet preparation with a closed water circuit, the material is fed via a 500 m long enclosed belt conveyor to the kilns.

1 Cleaning of washing water, sludge dewatering

On the firm foundation of the cleaning and filter know-how possessed by Baden-Württemberg’s plant engineering specialists Leiblein, of Hardheim, the basis of the assignment was defined as, on the one hand, cleaning of the washing water from preparation of “kiln stones” and, on the other hand, the dewatering of the sludge yielded. All facets of this target were fulfilled, on the basis of the interaction of the solids separator, inclined-plate (lamella) separator and vacuum belt filter used systematically in the process water circuit.

The water circuit starts with water from the preparation system which – in free fall and containing coarse elements of approx. 0.1 to 5 mm – flows into a solids separator for removal of these coarse particles.

2 Solids separator in the treatment process

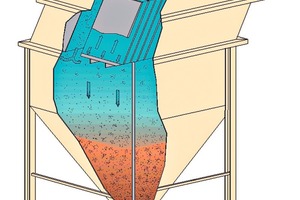

The process water is fed from above into the tank and flows downward; its flow is then reversed, and it is routed upward between plates and then leaves the tank again via an outlet weir. The sedimentable particles are removed during flow through the plates. From here, the solids slide downward into the sludge hopper, while the cleaned water flows over the outlet weir. The sedimented sludge is raised above the water level by means of a screw and is then taken to a sludge heap in skips. After passing through the solids separator, the process water finds its way again by gravity into the familiar Leiblein lamella separator.

3 Lamella separator –

Filter technology for optimum results

Similarly to the solids separator, the incoming water is firstly routed downward in the lamella separator (lamella clarifier), reversed, and then again routed upward via an array of plates. In this process, the suspended solids drop onto the inclined plates (sedimentation) and slide further into the sludge hopper. At Schaefer Kalk, the lamella clarifier, with its demanding treatment task, required an installation space of only around 3 x 4 m. Despite the low space requirement – a conventional circular thickener would have needed a site 12 m in diameter – design throughput is 100 m³ of water per hour. The low space requirement is also accompanied by a significantly lower need for flocculants, of only 70 %, against 100 % in a circular thickener. The use of a sludge level monitoring system ensures that the necessary pasteous consistency is achieved so that the thickened sludge can be reliably pumped to the vacuum belt filter to achieve the highest possible sediment extraction rate.

4 Vacuum belt filter for further sludge dewatering

This filter type is characterised by endless stainless steel filter belts of a fineness starting from 80 µm and operating with vacuum assistance. These permit the attainment of a high throughput rate and improved dewatering of the filter cake. All the filter variants achieve an extremely high saving on fresh water in the water circuit, since only 5 % to 10 % fresh water is needed to make good water losses caused by water adhering to the mineral product and the residual water content in the sludge.

5 Conclusion

Precise planning and prefabrication made it possible to complete on-site installation work in just a few days. In addition, the Leiblein filter system installed at Schaefer Kalk has a modular structure which will permit the integration of further lamella separators without difficulty if water throughput increases. Filter performance in Schaefer Kalk’s limestone preparation installation at its Hahnstätten plant is assessed unanimously as positive, and substantiates the plant’s claim to use water resources carefully and economically for the sake of the environment.

//www.leiblein.de" target="_blank" >www.leiblein.de:www.leiblein.de

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.