1 Introduction

Cement demand in India was boosted by strong economic growth and government investment in infrastructure development. The Indian cement industry experienced a good growth in cement demand from FY 05/06 to FY 08/09. Cement demand in FY 11/12 was better, however, with a consumption increase of 6.6 % across India as per Cement Manufacturer Association (CMA). Housing construction and government infrastructure investment has helped in increasing the demand. Cement consumption grew by 13.8 % in the Western region, in the Northern region by 11 %, 9.3 % in the Central region and 2.9 % in the Eastern region.

Due to the demand, almost 63 million tons of new cement production capacity has been established during the past two years as per CMA. It is expected that India’s cement growth will be 6–8 % in 2013 as housing and rural demand (for cement) have been the key drivers. Interest rate cuts have helped to stabilize the real estate markets. As per CMA, India’s cement industry will achieve a capacity of 550 million t/a by 2020, in other words, an addition of another 230 million t/a (current production is 320 million t/a).

In view of the above, the task of obtaining limestone resources suitable for cement manufacture is a challenging one as high grade deposits are depleting at a much faster rate. This situation is compelling the cement producers to go for judicial blending (of marginal grade with high grade limestone) and beneficiation of low/medium grade limestone. This act will have a significant impact on the life of mines and plants.

2 Limestone deposits – scenario

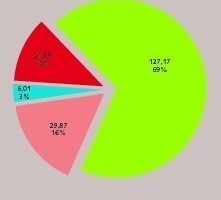

The National Council for Cement and Building Materials (NCCBM) and the Indian Bureau of Mines (IBM), government of India has been carrying out the compilation of the National Inventory of Cement Grade Limestone. As per IBM on 01.04.2010 the total limestone reserves and resources of India is 184.935 billion tons. Category-wise availability of limestone in India can be classified as given below in Figure 1.

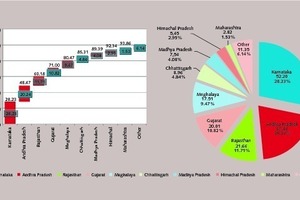

Though limestone deposits occur in 24 Indian states and 2 UTs, 48 % of the total limestone resources are concentrated in Karnataka and Andhra Pradesh only. Another 32 % are concentrated in Rajasthan, Gujarat and Meghalaya. Hence, 80 % is concentrated in five states only. The state-wise distribution of limestone in India is given in Figure 2.

As per IBM data, out of 124 539.551 million tons of Portland cement grade limestone, the total resources of cement grade limestone reserves is 8948.926 million tons and the total remaining resources is 115 590.625 million tons (Table 1).

However, approx. 30 % of the resources i.e. 34 677.188 million tons lies beneath forests (22.5 %) and other regulated areas (7.5 %), which may not be available for cement production. The availability of limestone reserves for future requirements is shown in Table 2.

Based on the expected growth and current consumption pattern, the above shown reserves are expected to last only for another 35 to 41 years. As per estimates, approx. 27 % of the total Indian limestone resources are low to marginal grade.

2.1 Brief account of marginal grade deposits in India

Many marginal grade deposits are found which are not useable directly in clinker manufacturing. Such low/marginal grade limestone deposits occur along with cement and other grade limestone in the Kaladgi and Bhima basin of Karnataka, Narji limestone of Andhra Pradesh, and Vindhyan limestone of Madhya Pradesh, Rajasthan, Uttar Pradesh and Jharkhand, Chhattisgarh Super Group in Chhattisgarh and Kallankurichchi & Niniyur limestone of Tamil Nadu. The occurrence of prominent marginal grade limestone in India is shown in Figure 3.

2.2 Specification of limestone for cement manufacture

Limestone is the principal raw material in cement manufacturing. About 1.55 tons of limestone together with minor amounts of correctives and about 0.15 tons of coal are required to produce 1 ton of cement. The broad chemical composition of limestone for cement production as per NCCBM norms should be as shown in Table 3.

3 Technological options for limestone beneficiation

A process which improves the limestone quality so as to produce it at an economical cost for its use as raw material is broadly defined as “beneficiation”. Careful quarrying and selective recovery are factors in this process, but the chief aspects of beneficiation are processes such as crushing and screening, washing, grinding, flotation and heavy-media separation. The choice of beneficiation depends on the nature of the gangue present and its association with the ore structure. Several techniques are available to enhance the quality of limestone.

The technological option for beneficiation of limestone depends mainly on the specific requirement of a particular project, keeping in view the characteristics of limestone plus the requirement of the customer – cement plant and economics.

Some of the approaches should probably not be included under the term “beneficiation”, although the goals are the same. Currently steps taken to improve the quality may be summarized as follows.

3.1 Cleaning of deposit before quarrying:

a. �Stripping by mechanical or hydraulic means

b. �Combining this process with another recovery operation that produces usable or commercially saleable material from the “overburden”

3.2 Selective recovery dictated by:

a. �Variability of deposit controlled by stratigraphic changes and/or the effects of weathering (usually a factor of “vertical” significance in a deposit, unless complicated by structure).

b. �Sedimentation and life-form variations originally imposed in the environment of deposition.

c. �Structurally imposed limits; e.g. fault planes, flow thickening, overburden thickening, etc. (the latter may require underground mining).

d. �Chemical changes due to dolomitization, leaching, mineralization, etc. Recovery may be guided by three-dimensional studies of the quarry and may be accomplished by sorting of the product in the quarry.

3.3 “In plant” processing of stone, including:

a. �Crushing and screening – with material flow arranged to reject certain selected size grades of ma-terials for quality reasons.

b. �Washing – with discard of selected size grades isolated usually by screening or classifiers.

c. �Sorting – varying from hand picking to elaborate recently developed photocell-circuit sorting, based on light-reflectivity properties.

d. �Grinding and classification – discard of selected size grades after sorting by classifiers is common.

e. �Flotation and concentration – following grinding and size classification, usually with a fairly complicated flow.

f. �Heavy-media (sink-float) separation – also relatively complicated and of particular interest when wide variations in specific gravity occur.

Blending is the most highly developed and widely used method of “beneficiation”. A system of utilizing poor-lime limestone and upgrading it to usable quality, simply by addition of high-calcium material, achieves the same end as classic beneficiation.

4 Results of a few beneficiation studies

Various studies for beneficiation of marginal to low grade limestone have been undertaken by different agencies using the methods listed above. The methodology adopted depends on the quality of limestone, the nature of impurities etc. Results of a few studies worth mentioning are discussed below:

A. �The low-grade limestone of the Shahabad area assayed at 34.0 % was subjected to various laboratory investigations for the purpose of meeting industrial requirements; the flotation process was carried out. The increase in the concentration of lime was about 9.2 %. The results of the final concentrated product is 43.2 % CaO, 16.9 % SiO2, 2.4 % Fe2O3, 6.8 % Al2O3, 0.7 % MgO and other traces.

B. �The limestone sample from Kota, Rajasthan, was analyzed with 41.45 % CaO and 13.52 % SiO2. Calcite was the predominant mineral associated with quartz, mica and minor amounts of limonite as gangue minerals. The locking and liberation studies indicated that the calcite was liberated from the gangue at a size below 105 mm size. The gravity methods of separation as a pre-concentration method did not yield encouraging results and hence froth flotation technique was chosen to reduce the silica content. Flotation studies indicated that at a grind of 86.2 % - 105 mm size, a concentrate obtained analyzed 50.15 % CaO and 5.01 % SiO2, with a yield of about 50.0 %. The concentrate thus obtained was quite suitable for the use in the industry.

C. �Beneficiation of a low-grade limestone sample from Salem, Tamil Nadu, was carried out by a pilot scale flotation column. Mineralogical studies have revealed quartz, feldspar, pyroxene and biotite as gangue minerals while pyrite, in trace quantities, appears as opaque along with dominating calcite. Reverse flotation was tried using two different commercial amines viz. Chem750F and Flotamine-D. The studies clearly suggested that it is possible to produce a limestone concentrate assaying at around 96–97 % of CaCO3 with less than 1 % SiO2.

5 Blending with sweetner grade limestone

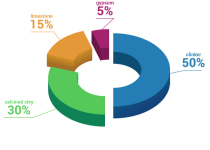

Blending of low grade limestone with high grade limestone as sweetener is a common practice in the cement industry. High grade limestone within India occurs in the states of Himachal Pradesh, Rajasthan, Madhya Pradesh, Andhra Pradesh, Karnataka and Gujarat as shown in Figure 4.

6 Conclusion

The need of the hour is to utilize such marginal grade limestone for cement manufacture in view of prolonging the life of the mine and the plant. Many beneficiation techniques are available. An appropriate, viable, sustainable method is to be implemented depending upon the mineralogy and chemistry of such marginal grade limestone deposits. This technique(s) would make such marginal grade limestone located in areas of lucrative markets useable for cement production.

Acknowledgement

The authors are grateful to Mr Arvind N. Pathak, CEO of the Reliance Cement Company Private Limited, Mumbai, for the permission to publish this paper.