Treatment of bypass dust in cement manufacturing

Indexing belt filters from BHS-Sonthofen enable the bypass dust accruing during clinker manufacturing to be completely reincorporated into the process by using up to 100 % of more cost-effective alternative fuels in cement kilns. Reincorporation of the salvaged bypass dust increases cement production by up to 3 %. Proof is provided by a new plant having a 20 000 t annual capacity that the method works reliably on a commercial scale.

1 Introduction

Fuels such as coal, oil or gas used to manufacture cement are increasingly being replaced by clearly more cost-effective alternative fuels such as car tires, plastics, sludge and municipal and industrial waste. The percentage in Europe has already increased to around 60 % and will rise even further in the years to come.

More chlorides are released in the combustion process, however, when using alternative fuels, in comparison to fossil fuels. These chloride salts evaporate in the sintering zone, which result in the formation of internal circuits (gas recirculation). The subsequent...

1 Introduction

Fuels such as coal, oil or gas used to manufacture cement are increasingly being replaced by clearly more cost-effective alternative fuels such as car tires, plastics, sludge and municipal and industrial waste. The percentage in Europe has already increased to around 60 % and will rise even further in the years to come.

More chlorides are released in the combustion process, however, when using alternative fuels, in comparison to fossil fuels. These chloride salts evaporate in the sintering zone, which result in the formation of internal circuits (gas recirculation). The subsequent condensation causes the chlorides to concentrate in the hot meal and thus to produce baked-on deposits in the plant components. Therefore, the chlorides must be discharged from the cement kilns using a gas bypass. The chlorides present as gases in the kiln infeed settle on the bypass dust during cooling of the gas flow extracted from the gas bypass. This dust exhibits a chloride content of up to 20 % in many cases. It cannot be added back into the cement, because the maximum permissible chloride content of 0.1 % is exceeded in the end product.

2 Indexing belt filters reduce the chloride content

So that cement factories can also take advantage of the cost benefits of alternative fuels and at the same time do away with disposal costs for bypass dust, the system manufacturer A TEC developed a patented process in cooperation with Holcim, which was realized in the factory located in Rohoznik, Slovakia as a complete industrial scale system with BHS belt filter system. It reduces – even when starting with high concentrations – the chloride content of the dust to below the desired threshold. The BHS belt filter, which assumes an important process step in this system, achieves a chloride wash-out efficiency of more than 95 %. Therefore, the bypass dust can be added to the cement again - i.e. sold - even when using secondary fuels. The concept from A TEC and Holcim is also based on the recovery of valuable KCl salts from the filtrate, thus turning the bypass dust into a resource for new recyclable materials. Furthermore, the system requires only a minimal amount of water.

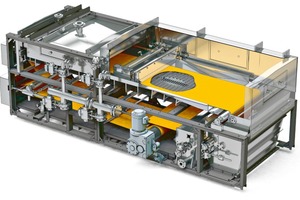

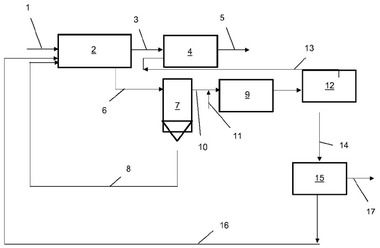

The core element of the systems is the BHS indexing belt filter, type BF. The gas flow extracted from the burning process – with which the bypass dust is discharged from the system – is cooled and freed from dust. The dust separated in the filter system is sludged with washing liquid and then filtered, washed efficiently in multiple stages counter-current wise and mechanically dewatered to the greatest possible extent. The material flows extracted from the belt filter are a mother filtrate concentrated with chlorides, which is treated or disposed of, as well as the washed out filter cake which is added back to the cement.

BHS uses indexing belt filters, because they are clearly advantageous for typical flow rates of approximately 3 to 9 t dry substance per hour – in comparison to filter presses, for example. They are especially suitable for high flow rates because they work continuously. The multi-stage counter-current washing of the filter cake works efficiently and the special mechanical dewatering system makes ongoing use of the filter cake easier. The belt filter system is fully automatic including the cake discharge and filter cloth washing. The belt filter is easy to clean and maintenance costs are low.

3 The technology in detail

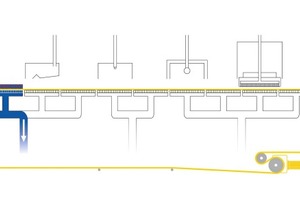

The dust to which the chlorides and combustion residues stick is first conveyed from the storage silo into a mixing unit – for example, a BHS mixer – where it is sludged with water or filtrate and then pumped to the indexing belt filter and continuously fed onto the belt.

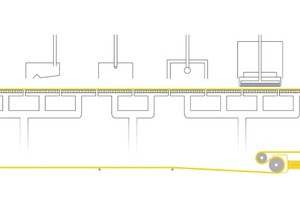

The BHS indexing belt filter is operated in cycles: The belt stands still while filtration is active and the vacuum is applied. The filtrate is drawn off in the filtration zone and an even filter cake is formed. The trays under the filter cloth are ventilated at the end of the cycle and the belt moves in the direction to the washing zone by one zone length.

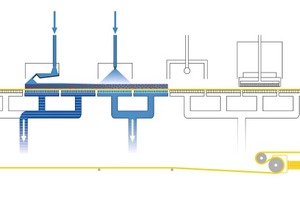

A bypass dust filter is typically equipped with two or more washing zones. The washing filtrates are extracted and collected separately. The filtrate from the first washing stage can be used to prepare the suspension; the filtrate of the second wash is recycled and used for the first cake washing. Therefore, fresh water is used only in the second stage and the need for fresh water is reduced to a minimum.

With this two-stage counter-current process, BHS achieves a washing efficiency of more than 95 % – considerably more than using two parallel washing stages using the same wash ratio, both of which need to use fresh water. The first washing filtrate to be released as a result of this operation contains a high concentration of chlorides. It is used to sludge the dust.

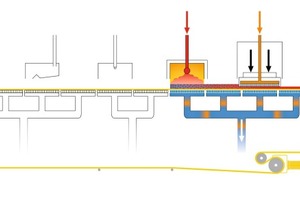

After washing, the filter cake is cycled into the dewatering zones. In order to reduce the residual moisture content of the filter cake, water is removed initially by vacuum drying after washing. An additional pressing device follows this zone. Here the filter cake is mechanically compressed. At the same time, compressed air is blown through the pressing device and filter cake, which dissipates the pore fluid in the cake. This is allowed by a perforated plate covered with a filter cloth. The pressing force is 3 to 6 bars of pressure, depending on the filter width; the blowing pressure is between 1 and 2 bars of pressure.

Using this combination of indexing belt filter and an additional pressing device, BHS reduces the residual moisture in the bypass dust to 25 to 30 %. The value also falls below the thixotropic point and handling is improved, because the dried filter cake is crumbly and can be transported away by the conveyor belt and directed back into the process.

The cake is removed from the filter cloth at the end of the filter. A scraper supports this process. Special filter cloth washing is installed after the discharge which mechanically removes adhering product residues from the filter cloth. The discharge from cloth washing can be used for cake washing. This method further minimizes the use of fresh water and the solids contained in the cloth washing water can be directed back into the filtration process.

4 A worthwhile investment

Once the bypass dust leaves the belt filter system, its chloride content is far below the level of the accruing dust from the gas bypass (wash-out rate > 95 %) and all the dust can be directed back into the process.

The quintessence: Even if cost-effective secondary fuels replace conventional fuels for the calcination of the raw material by 100 %, the accruing bypass dust can be directed back into the process. Chloride-containing filtrate, removed from the system, can be treated or disposed of.

BHS provides a complete solution for treating the bypass dust: The scope of supply includes the dosing and mixing station, the filtration system with filtration of the suspension and cake washing using a multi-stage counter-current method and the cake dewatering, all pumps and the separators as well as the complete array of measuring and control technology. The system is therefore easy to integrate into the existing process as a skid-mounted module – as a “black box”.

An initial pilot plant with a BHS indexing belt filter provided proof that the process works reliably on a commercial scale. The system has an annual capacity of 20 000 t.

5 Summary

With a new complete solution for the treatment of bypass dust, BHS makes it possible to use cost-effective alternative fuels for cement production, such as auto tires, plastics, sludge and municipal and industrial waste in place of conventional primary fuels such as coal, gas and oil. The central element is the treatment of bypass dust containing chloride using an indexing belt filter. It removes the chlorides and residues that result when burning these substances, so that 100 % of the bypass dust can be directed back into the manufacturing process and sold. As a result, the BHS belt filter increases cement production by up to 3 %. The end products of the process are only recyclable bypass dust and a filtrate concentrated with chlorides and combustion residues.

//www.bhs-sonthofen.de" target="_blank" >www.bhs-sonthofen.de:www.bhs-sonthofen.de

Please see ZKG International 11/2015,

pages 28 – 43

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.