Through the middle of the rainforest

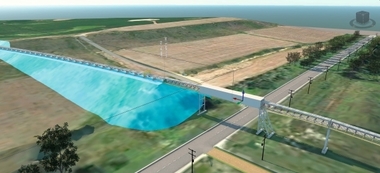

The CL Systems division of the Beumer Group has also been very successful in Indonesia. The plant construction company Sinoma International Engineering Co. Ltd. was awarded the contract by the Indonesian end-customer, Cemindo Gemilang, to supply a turnkey cement plant to Java with a clinker production of 10 000 t per day. Sinoma commissioned Beumer with the design and supply of an overland conveyor between the quarry and the plant.

The challenges in this project were not only the demanding topographical routing but also the evergreen rainforest. Joint discussions were held between the Beumer...

The CL Systems division of the Beumer Group has also been very successful in Indonesia. The plant construction company Sinoma International Engineering Co. Ltd. was awarded the contract by the Indonesian end-customer, Cemindo Gemilang, to supply a turnkey cement plant to Java with a clinker production of 10 000 t per day. Sinoma commissioned Beumer with the design and supply of an overland conveyor between the quarry and the plant.

The challenges in this project were not only the demanding topographical routing but also the evergreen rainforest. Joint discussions were held between the Beumer team, Sinoma and the end-customer, and various routes were worked out and compared. The very narrow corridor of land in addition to the tropical climate required a complex and sophisticated design. Among other things, the Beumer team designed a solution with tight horizontal curves that fitted optimally into the landscape.

The entire system now comprises six conveying plants with a total of length of 7.6 km. Beumer also supplied acceleration and discharge conveyors and a PLC plant control system.

Controlled loading ensured

The system is designed for a maximum continuous conveying capacity of 3000 t/h. The main component is a 7.4-km-long overland conveyor. Upstream of this troughed belt conveyor is an intermediate hopper with a capacity of about 120 t. The material passes from this hopper via a variable-speed discharge conveyor to a downstream acceleration belt that feeds the overland conveyor. This controlled loading system ensures cost-effective operation of the plant, especially during the start-up phase. It also has a favourable effect on the dimensioning of drive components and the belt, and reduces the operating costs.

The acceleration belt with a speed of 4 m/s protects the belt of the overland conveyor and increases its service life. For further protection there are also upstream units for collecting any iron and non-ferrous metals. The limestone is then transported to the blending bed on short troughed belt conveyors.

The troughed belt conveyor has a width of 1200 mm and a distance between centres of 7381 m. One tail drive and two head drives are installed, each with a rating of 545 kW. The plant conveys the material at a speed of 5 m/s and negotiates a height difference of minus 188 m.

Protection of people and animals

The conveying system also runs past villages and for long sections passes through rainforest that deserves to be protected. The CL Systems team has taken numerous design measures to reduce the noise impact on people and animals. Among other things, silent idler rollers and appropriately dimensioned protective hoods have been used at the drive station. This means that the limestone passes through the rainforest in virtually silent mode. The construction time lasted only a year and the plant went into operation after 1.5 months.

//www.beumergroup.com" target="_blank" >www.beumergroup.com:www.beumergroup.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.