The Three-Level-Conversion-Strategy

With the experience from more than 1000 conversions in only 15 years one thing is certain for Aumund: it will pay off for the client to modernize a tried and tested machine by conversion. A replacement investment will be significantly more expensive in most cases. For the material handling specialists, the extensive knowledge and experiences as manufacturer and the technological expertise of the company’s engineers and technicians are the base for the success of every conversion project.

1 Rising demand for conversions

The constantly rising demand for conversions prompted Aumund Fördertechnik early on to systematically offer the expertise available in the company on the market. The cooperation of young employees with experienced engineers, linked to the close cooperation with customers results in new synergies from the outset in product advancements as well as in project solutions. Also the necessary knowhow on conversions thus grows constantly.

As the conversion project at Märker GmbH indicates, there is not always the need to invest in a new machine. Often the conversion of...

1 Rising demand for conversions

The constantly rising demand for conversions prompted Aumund Fördertechnik early on to systematically offer the expertise available in the company on the market. The cooperation of young employees with experienced engineers, linked to the close cooperation with customers results in new synergies from the outset in product advancements as well as in project solutions. Also the necessary knowhow on conversions thus grows constantly.

As the conversion project at Märker GmbH indicates, there is not always the need to invest in a new machine. Often the conversion of an existing machine is economically more sensible providing the same level of quality and reliability. For instance, the reutilization of the steel structure leads to significant cost savings of about one third compared to the installation of a new machine. A further argument in favor of conversion is the short assembly time and the resulting reduced downtimes and loss of production. The conversion of a bucket elevator only needs a fraction of the time normally planned for dis-assembly and re-assembly of a new installation.

2 Four good reasons for conversion

Looking back on more than 1000 conversion projects, there are four reasons in favor of conversion: increasing the capacity of the installation, adaption of the machine to the spatial conditions and changes to the plant or to the production sequence. Besides quite frequently, the original supplier of the machine has left the market, so there are additionally problems with maintenance and obtaining spare parts.

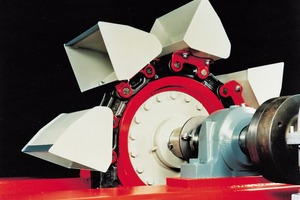

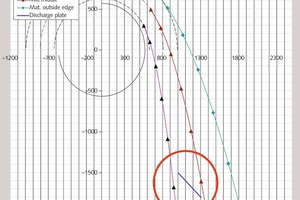

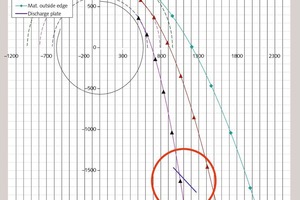

If and how far the capacity of a machine can be increased, has to be determined in each individual case. Experience shows that for example the conversion of a round link chain bucket elevator into an Aumund chain bucket elevator with central chain (Fig. 1, 2) will result in a doubling of performance. As the case may be adapting the material feed and material discharge might become necessary in this context. To achieve an optimum discharge process with a bucket elevator, the process is analyzed by means of a digitally calculated discharge parabola (Fig. 3). Adaptions of the material discharge based on the analysis of the discharge parabola optimize the discharge of the material into the discharge area (Fig. 4).

For example the transport routing or the number of discharge stations can be changed. Aumund engineers survey and record the changed situation on location and develop a suitable conversion concept for the already existing installations in close cooperation with the customer. Aumund advances its machines based on new insights form materials research and based on new technologies. That way, the company’s engineers developed a method to increase the lateral stability of bucket elevator belts.

Within its core, the respective Aumund belts have a layer of longitudinal, uninterrupted steel chords providing for longitudinal stability and a layer of transversal steel chords granting transversal stability. A conversion of chain bucket elevators to belt bucket elevators with that type of Aumund belts carries not only economic advantages. The lower weight of a belt in comparison to a chain, makes reaching significantly greater heights than with a chain bucket elevator possible. At the highest bucket elevator worldwide, covering a conveyor height of 175 m at Ambuja Cement in India, the existing bucket elevator of another supplier was converted into an Aumund bucket elevator during a conversion project.

In some industries, the life span of the machines is longer lasting than the market presence of the producer or provider. Sooner or later that will cause the problem, that maintenance and the supply with spare parts cannot be ensured by the original provider. A conversion provides a “new life” to that kind of time-tested and well working machines. When converting such an installation, the technicians and engineers first research, if there are still design drawings available. If there are no drawings, those needed for the conversion are reproduced. Necessary conversion parts are taken from the Aumund original parts product range. So apart from the conversion, Aumund can guarantee a long-term replacement part delivery service. Additionally, the company’s Preventive Maintenance Service PREMAS® can be offered.

3 The “Three-Level-Strategy” by Aumund

Conversions are always a tightrope walk between tailor-made and hence expensive solutions for the customer on one side and cost efficient but often technically limited standard solutions on the other side. Based on its producer’s authority, Aumund has developed a standardization of the parts to be used and the process steps to be executed. In each individual case, these standards are brought together to form a conversion solution optimized for this client. In the process it is rather helpful, that after more than 1000 conversions the company’s specialists are not only well versed with their own machines but also with the machines and installations of the competitors and of the producers not present in the market anymore.

Conversion Level I: the traction mechanism like chain or belt will be replaced. Usually these are central chain bucket elevators (BWZ), belt bucket elevators (BWG) or deep drawn pan conveyors (KZB, Fig. 5). The buckets of the bucket elevators, the drums or the drive train are re-used unchanged. Just a minimum of new replacement parts will be inserted into the machine.

Conversion Level II: here all parts with the exception of the steel structure are replaced. When converting a round link chain bucket elevator into an Aumund central chain bucket Elevator for example, the drive including the drive shaft and all bearings, the buckets with their mounts to the traction mechanism and the complete tension axle are replaced besides the traction mechanism.

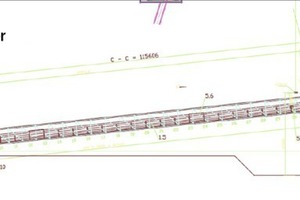

Conversion Level III: beyond the range of level II the steel structure is replaced as well. For instance, this can include changing the course of a deep drawn pan conveyor when permitted by the space available (Fig. 6).

Conversions are continuously monitored and directed by Aumund supervisors, engineers and technicians. So the customer can rely upon a sustainable quality assurance.

4 Conversions are also of interest for other

industries

The “Three-Level-Strategy” by Aumund is based on standardized and thus reliable procedures reaching from supplying replacement parts to a complex conversion solution. However, the services are not limited to the cement industry. For each enterprise relying with its production process on installations for the mechanical transport of bulk material, a conversion can be the alternative to a significantly more expensive replacement investment with a comparable result.

At the RWE Power AG power plant located in Grevenbroich-Neurath, Germany, a total of 16 arched belt conveyors serve the coal pulverizers of block-units F and G as coal feeders. The block-units produce 1100 MW each and have been equipped with an optimized systems engineering directly at construction in 2012. However, the installed pan conveyors of another producer did not correspond with the demands of the operating company. A short time after the initial start of operations already, Aumund Engineers conducted an inspection of the existing conveyor. They noticed that the existing pan conveyors based on round link chains by a third-party manufacturer were heavily worn after a short time in operation. Besides, they displayed significant mechanical shortcomings and did not fulfill the customer’s demands concerning pressure tightness. Extensive downtimes and high maintenance costs were the consequences. Due to the structural shortcomings and the connected costs of maintenance Aumund was contracted to optimize the existing pan conveyors just two years old. After a thorough survey of the situation and the existing machines, a conversion according to Level II was started.

During the rotationally planned downtimes of the plant the existing conveyors were converted by conversion specialists while the boiler kept working. Thus a general overhaul of the heavily worn conveyors resulting in unplanned boiler downtime could be avoided.

The housings of the old machines were mostly preserved and additionally reinforced. At the machines exterior transmission, drive and bearings were reused. In contrast, in the interior all components including the drive shafts were replaced with Aumund Machine Parts of the BPB 250 line. To reduce the chain breaking load and to avoid the warpage of the catches, the existing cleaning conveyor was converted from two-strand to three-strand design. All drive units of the 16 coal feeders of the machine as well as of the cleaning conveyor were retained. During conversion RWE decided to introduce light pan conveyors with an average performance of 150 t/h. During peak times, the conveyors can transport 200 t/h.

The adaption of the new machines to the existing casings made some constructive changes necessary, to achieve simultaneously accuracy of fit and the necessary conveying performance of the machines. Aumund decided upon welded pan conveyors, which had to be adapted very individually for the connection to the hopper.

To reach the demanded conveying performance at maximum speed, the conveyor cross section was optimized in a way that it could be inserted into the existing space. Due to the feeding of the coal pulverizers at negative pressure, special attention to an improved sealing of the entire casing was paid.

The occurrent material loads at the bunker chutes could not be taken by the original angular sheets. The occurrent material loads at the bunker chutes were brought under control by installing a baffle beam. With an increased board height, the feedback conveyor had to be lowered. Besides, a smaller sprocket wheel was used. While equipping the pan conveyors, the designing engineers selected the Aumund chain AU6052. With the newly selected chain system the service life could be significantly extended compared to the previously used round link chain. The use of new catches between the chain strands and the lowering of the tensioning axis completed the conversion. Within this project, Aumund undertook construction, production and installation supervision.

5 Conversions have a future

During the last more than 90 years, Aumund Fördertechnik GmbH has developed into a specialist for the transport and storage of difficult bulk material. For the last 15 years, conversion and modernization of existing machines from own or external production has been a special area of expertise. Those machines can be found in the cement industry as much as in metallurgy, in power plants, in the minerals industry and in mining. With all these industries, the international competition is permanently growing. On the one hand that makes costs a permanent issue. On the other hand the minimizing of downtimes gains significantly in importance. Downtimes mean a loss of production and loss of production quickly sees the loss of customers and the weakening of the own position in the market as the consequence. Therefore, shorter downtimes at low costs are two deciding characteristics granting a future to conversions in this market environment (Fig. 7).

However, with the successful conversion of a machine, the work is not done yet. With Aumund, its maintenance and monitoring is also in well-tried hands. The worldwide network of eight branch offices and numerous representations, six spare parts depots and service centers guarantee a comprehensive service close to the customer for a long time after the conversion and a longtime secured spares supply.

6 Summary

For economical and forward-looking as well as technological reasons, the conversion of a machine is a notable alternative to the new acquisition of a bucket elevator, a pan conveyor or another machine for conveying bulk material. Cost savings of 30 % and more speak a clear language. Besides, a conversion causes significantly less downtime and loss of production than the installation of a new machine.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.