Samson Feeder in new operation modus

Quick reaction to changing demand and changing short-term fuel or raw-material costs is the most decisive factor to a profitable plant operation in the modern cement industry. However, a production process involving deep pits, bunkers or bins demands the construction of massive foundations and a geography, where it is possible to dig deep down. A quick relocation of the machinery due to changing production processes or evolving market situations is impossible. Flexibility remains rather limited. Thus, Aumund Corporation located in Atlanta, GA/USA has found an additional application for the...

Quick reaction to changing demand and changing short-term fuel or raw-material costs is the most decisive factor to a profitable plant operation in the modern cement industry. However, a production process involving deep pits, bunkers or bins demands the construction of massive foundations and a geography, where it is possible to dig deep down. A quick relocation of the machinery due to changing production processes or evolving market situations is impossible. Flexibility remains rather limited. Thus, Aumund Corporation located in Atlanta, GA/USA has found an additional application for the Aumund Samson® Feeder.

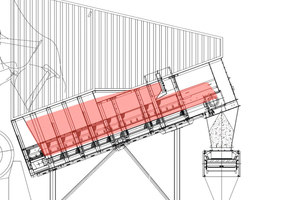

As it turns out however, the cement industry rarely needs the vast buffer storage provided by bunkers and bins. The storage capacity provided by a Surface Storage Feeder (SSF) like the Samson® feeder has proven to be fully sufficient. It is surface mounted without the need for special foundations and it can be relocated rather easily within the plant or even between sites, should the need arise. Furthermore the SSF can handle materials of different consistency from cohesive and sticky to abrasive and beyond. It can be supplied in virtually any size and length to build a buffer capacity based on the plant’s needs (Fig. 1).

The SSF receives material directly from either rear tipping trucks or front end loaders. The entry section provides a certain storage capacity within the unit itself for initial material receiving with quick vehicle turnaround times, and the total amount of storage depends upon the application, material density, feed rate and size of the unit. The SSF keeps a constant level of material within its head chute to act as a surge bin which is then extracted at an either constant or variable rate determined by the customer by means of a weigh feeder, weighing belt or a similar device.

A combination of several SSF units can be used when more than one material is to be added. The different materials can be metered at determined percentages based on the plant’s needs. Enclosures on the SSF can also be included to prevent environmental impact when handling dusty materials or materials that need to be kept dry. The key element of the feeder’s flexibility and performance is the fact that material is stored horizontally. In no case can the material height exceed the width, therefore bridging is impossible. Also due to the large width, high storage capacity is possible. The conveying and discharge function is carried out at very low belt speed. This allows a higher belt angle than would be otherwise considered, resulting in compact elevation rise to allow weight feeder or conveyor belt loading.

Cement plant design for raw mill feed incorporates an additive covered storage area which frequently utilizes front-end loaders to load multiple materials via a hopper and feeder. This feeder, apron or other type, feeds a long conveyor belt system with reversible belts or multi-chute system to distribute the additive to 3 to 5 bins. Such a layout dictates that the additive storage area must be some distance from the feed bins to allow a 15 degree belt to convey material to the top of the raw mill feed bins. The various additives are then metered out of the feed or buffer bins. Depending upon the material properties these bins will have to be of special construction and inefficient storage shapes in an attempt to resolve anticipated flow problems. Often expensive liners and special feeders, like rotary plough type, have to be used. If hard rock limestone or additives are required, apron feeders combined with belt weigh feeders may be needed. These metering devices and the assortment of feeders then finally feed onto the mill feed belt. All in all this is a very complex and expensive installation. It requires a lot of maintenance and by experience it is a main cause of mill downtime. Not to mention that if the plant wants or needs to use other raw material resources in future, significant modifications or feeding problems might occur.

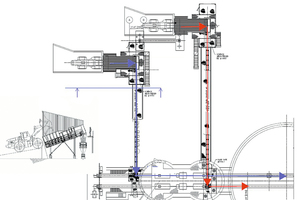

To avoid all these complications, in the ideal plant layout, the additive storage building could now be placed next to the mill feed belt by using the Samson® Feeder as an SSF. The entire special bins, feeders, belt transfer and distribution systems are to be eliminated. The loader now feeds additive directly to the SSF units. A bank of 3 to 5 of those units can be arranged along the storage building which would feed, via weigh belt feeders, directly onto the mill feed belt. Each feeder receives material by loader. The feeder in turn maintains a level of material in the outlet chute, which feeds the weigh feeder. Due to the SSF’s wide profile of ten feet, maintaining such a material level is no problem. Even if time between loading the unit creates gaps on the feeder, the constant material supply to the production process can be maintained by relying upon the buffer function of the SSF. Its variable speed maintains the needs of the weigh feeder and the weigh feeder meters the requirements of the raw meal mix and grinding process. For operation and maintenance, the plant has only 3 or 4 SSF and belt feeders to deal with. All those are located on ground level.

Aumund provided two Samson® feeder systems to Lehigh Cement at Edmonton in Canada (Fig. 2, Fig. 4). The task was to feed synthetic gypsum into separate finish mill lines. The material is loaded into the Samson® feeders by front end loaders. Through a weigh feeder and a TKF chain conveyor it is then fed directly onto the finish mill belt conveyor.

To the Lafarge cement mill at Whitehall in Pennsylvania/USA (Fig. 3), Aumund supplied one Samson® feeder. In conjunction with a weigh feeder and a transfer conveyor belt, it feeds lime mud directly onto the finish mill belt. The material is fed into the Samson® by both, rear tipping truck and front end loader.

Beyond simplifying the material feeding process at a cement plant, the use of the Samson® feeder opens up many further new opportunities. This type of wide surface storage feeder offers a flexibility far beyond conventional storage/feeder systems with less installed cost and less maintenance. Horizontal storage, although not a new concept, may now be a concept that has come of time, due to equipment development and evolution.

In the Americas installation costs have become by far the greater percentage of the overall total cost of any industrial project. Equipment, such as the SSF, offers an opportunity to reduce installed cost in some critical areas of a plant, while also offering some real operational benefits.

The Samson® feeder used as an SSF is providing an all-purpose solution for the reception of many types of bulk material cargoes transferred from the port to storage or production facilities by tipping truck or front end loader. For new plant developments the surface mounted SSF solution has offered an economical and flexible alternative to conventional underground unloading systems, storage bins and feeders.

//www.aumund.com" target="_blank" >www.aumund.com:www.aumund.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.