Quality assurance and process control in modern cement plants

Modern analytical methods are meanwhile standard in the cement industry for use in quality and production control.

Assurance of quality and performance

The functions of a modern plant laboratory are numerous and diverse, must be completed promptly, and exceed the scope of testing required by the applicable standards. In addition to the obviously necessary assurance of the conformity of the products to the relevant...

Assurance of quality and performance

The functions of a modern plant laboratory are numerous and diverse, must be completed promptly, and exceed the scope of testing required by the applicable standards. In addition to the obviously necessary assurance of the conformity of the products to the relevant standard, HeidelbergCement’s overriding priority is to supply customers with products of constant high quality.

The attainment of this quality target necessitates monitoring of the product by means of sampling at regular intervals and during every production operation in the company’s cement plants, starting with the feed materials, and continuing up to and including shipment. The production operations conducted in the cement plants are comparable in principle, but nonetheless differ in their details, with the result that the emphases on quality assurance vary slightly from individual plant to individual plant.

Location-specific approaches

Laboratory solution in Ennigerloh

The feed materials are sampled at regular intervals by the shift laboratory technician. While the raw meal grinding facilities are operating, a manual sample is taken twice per shift from the belt weighers below the crushed limestone silos. All these samples are blended to prepare the above-mentioned daily average sample, and then forwarded to the chemical and mineralogical laboratory.

The first process operation at the Ennigerloh cement plant consists of production in the raw meal grinding facility of the kiln-feed raw meal from the feed materials. An average sample is collected for 30 minutes in each case downstream of the grinding installation and upstream of the raw meal silo, and then transferred to a container and conveyed to the central laboratory by means of a pneumatic post system. The sample is received every half-hour in the laboratory’s fully automated laboratory automation system, prepared, and its chemical composition then determined using the X-ray fluorescence (XRF) spectrometer. The digitally drafted analytical-result records are continuously checked by the duty shift. Any deviations in the raw meal’s chemical composition from the target values are corrected automatically, making it possible to balance out even slight fluctuations in the chemistry of the natural limestone and limestone marl. The result is a raw meal with an extremely homogenous composition – a precondition for the production of clinker of constant high quality. Storage of this raw meal in high-capacity raw meal silos results in further homogenisation prior to feed to the kiln.

Laboratory solution in Lengfurt

The first operation in Lengfurt is considerably more complicated. Due to the natural chemical composition of the limestone, which varies within certain limits, operations in the quarry are orientated around local geological circumstances. The location’s quality manager specifies how much material from which areas of the quarry are to be fed to the blending bed, where the first homogenisation of the feed material upstream of the raw mill takes place. Defined quantities of corrective components (silicon dioxide, iron oxide) are added to the freshly quarried material upstream of the raw mill. Downstream of the raw mill, a raw meal sample is taken automatically every hour and then analysed in the fully automated laboratory. The analytical data obtained is used for automatic adjustment of corrective component metering. The raw meal is then temporarily stored in six raw meal silos. The Lengfurt plant also features five kiln-feed silos. Each kiln-feed silo is filled simultaneously from a number of raw meal silos via a recirculating bucket elevator. The kiln feed is then fed from a number of kiln-feed silos via a bucket elevator to the kiln. This procedure serves the purpose of homogenising the kiln feed. The effectiveness of these homogenisation processes can be demonstrated on the basis of the lime saturation factor: standard deviation in the lime saturation factor downstream of the raw meal mill is 2 to 3 %, but only ≤ 1 % in the kiln meal.

Sampling on the cyclone preheater

The Ennigerloh and Lengfurt plants each operate a four-stage cyclone preheater. Samples of hot meal are taken continuously and automatically from the bottom cyclone and chemically and mineralogically analysed. Conclusions concerning the stability of the rotary kiln atmospheres are drawn from the results of analysis of these samples.

Analytics in the rotary kiln system

At Lengfurt, a defined sample quantity of clinker is taken once each hour from the flow of material and conveyed to the automated laboratory system by means of an automatic pneumatic post system. At Ennigerloh, only daily average samples are currently analysed. Chemical analysis (XRF) and quantitative mineral-phase analysis (Rietveld) by means of X-ray diffraction analysis (XRD) are performed on the clinker samples. The classical Bogue method of calculation of clinker-phase composition is an indirect procedure based on chemical analysis, whereas the Rietveld method achieves direct determination of mineral-phase composition.

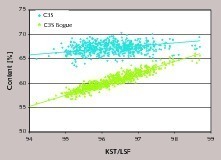

The direct Rietveld measuring method is used to determine elevated C3S contents in the clinker as an indirect Bogue calculation based on chemical analysis (Fig. 6). It is apparent here that the C3S content actually measured diverges from the lime saturation factor less strongly than that calculated indirectly. The Rietveld method thus supplies better substantiated information for control of production.

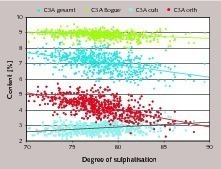

For the C3A contents significant trends can also be observed. The Rietveld method indicates significantly lower C3A contents than the Bogue approach (Fig. 7). The correlation between the orthorhombic and cubic C3A contents and degree of sulphation is also clearly apparent.

Thus, the Rietveld procedure supplies information which describes clinker composition significantly more accurately. Continuous measurement of mineral-phase composition with maintenance of constant Rietveld measuring parameters is used, on the one hand, for control of quality and, on the other hand, also supplies important information and statistical trends concerning the kiln process. The Rietveld method makes it possible to register deviations in mineral composition from the plant’s targets promptly and enables the laboratory to initiate corrective action, in close cooperation with the production department, extremely quickly.

Other feed materials

Cement grinding

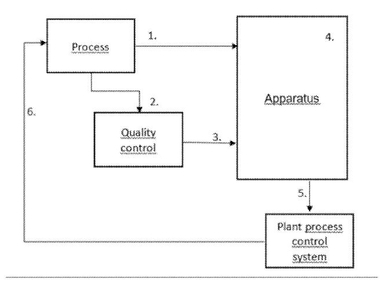

At both plants, the analytical results are continuously compared against the targets specified by quality management. The control room and shift foreman are informed promptly if the analysis data for a particular sample are outside the tolerance range. The shift foreman immediately begins his inspection of the plant system while the control room initiates the specified corrective action or, if necessary, stops the grinding process.

Test standards

At HeidelbergCement AG cement plants, all results are fed into the company’s internal laboratory information management system (LIMS) and compared against the plant-specific targets by the laboratory management at regular intervals. Special-property test requirements (low-alkali cements, high sulphate resistance or approval for use in carriageway surfaces, etc.), and country-specific monitoring tests (e.g. the Dutch KOMO symbol, the Belgian Benor mark), may be performed for non-German markets in addition to the testing requirements of DIN EN 197, Part 1. The conformity of the cements produced to the standards is certified by the Testing Laboratory/Inspection and Certification Body (German abbreviation: PÜZ) of the Research Institute of the Cement Industry. This outside monitoring body takes its own samples at regular intervals without prior notice and verifies in detail the plant’s own production control system.

In addition to performing round-the-clock quality assurance, the quality laboratories are also continuously available as contacts for customers. Solutions for specific applications or customers’ production problems are drafted rapidly throughout Germany on the basis of interdisciplinary cooperation with the construction consultancy department. This special service is an additional function which necessitates a high level of commitment and technical expertise on the part of the laboratory staff.

Expansion of the product range

Conclusions

In view of the high technical competence of the laboratory staff working in all three laboratory units, the extensive equipment and instrumentation installed, their direct proximity to cement production and the product diversity of the three locations (Ennigerloh, Geseke, Paderborn) they support, each central laboratory has a predestined role as a training establishment. A number of building materials inspectors are therefore also trained at Ennigerloh every year. In principle, HeidelbergCement also has an interest in training in the context of a so-called “dual study course”; one female laboratory employee is currently pursuing a Bachelor of Engineering degree. The cement industry will thus be able to rely on finding highly qualified staff for quality assurance, production monitoring and product development also in the future.

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.