Pneumatic conveying technology

for Dyckerhoff

Pneumatic conveying technology features prominently in handling the flow of materials in the cement industry. Blowers convey the fine material in pipelines throughout the production process. The requirements for the availability of the assembled units are high, as production would come to a standstill without blower air. Dyckerhoff has used Aerzen solutions for decades in its Lengerich cement plant, convinced by the innovative approach to air compression.

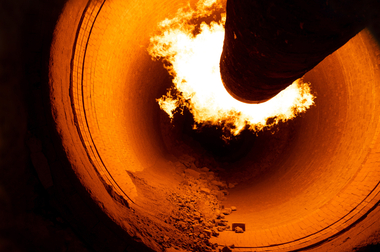

Hot process air is one of the most important energy sources in a cement plant. Dyckerhoff uses fuel oil for heating up, and then switches to pulverised lignite which is blown into the rotary kiln by means of a burner lance. The lignite burns immediately. In its kilns, Dyckerhoff can also burn derived fuels like fluff, a fibrous and high-calorific mass that consists mainly of chlorine-free plastics.

1 Blower technology for fuel supply

Dyckerhoff also uses the principle of pneumatic conveying technology to supply the burner. Positive Displacement Blowers (GM 25, 304 to 1452 m³/h, 55 kW max) of the...

Hot process air is one of the most important energy sources in a cement plant. Dyckerhoff uses fuel oil for heating up, and then switches to pulverised lignite which is blown into the rotary kiln by means of a burner lance. The lignite burns immediately. In its kilns, Dyckerhoff can also burn derived fuels like fluff, a fibrous and high-calorific mass that consists mainly of chlorine-free plastics.

1 Blower technology for fuel supply

Dyckerhoff also uses the principle of pneumatic conveying technology to supply the burner. Positive Displacement Blowers (GM 25, 304 to 1452 m³/h, 55 kW max) of the Delta Blower series are used here. The unit supplies a volume flow of 16 m³/min at a motor connected load of 36 kW for the transport of the pulverised lignite and fluff. The new Generation 5 Delta Blowers from Aerzen impress especially with their effectiveness.

The two units at Dyckerhoff ensure that the fuel from the silos reaches the burner nozzle under optimal pressure and in sufficient quantity.

Dust is generated during the production process, which consists of raw material, is separated by electrical gas cleaning (EGC) and collected in silos. Afterwards, the EGC dust is returned in the process – this is achieved by means of a conveying system where Aerzen Delta Screws (VML 18, 380 to 1190 m³/h, 75 kW max) provide the necessary volume flow of 18 m³/min in the pipes. Today, electric filters are an established technology for removing dust from exhaust air and for ensuring that the content of pure dust is significantly below 10 mg/m³. Dyckerhoff applies smaller positive displacement blowers (GM 4 S, 46 to 342 m³/h, 15 kW max) from Aerzen, which blow air into the silo via a pneumatic bottom, and which regularly mix the material with an air volume of 6 m³ per minute.

The unit is located in the area where the raw preparation of the untreated meal takes place. A vertical mill crushes the limestone into a fine pre-dried meal which is blown through transport piping from a storage silo into the heat exchanger which is more than 100 m high. Here, the raw meal is brought to temperature and flows through zones which are progressively hotter and hotter, until it finally reaches the furnace intake of the rotary kiln. The mineral mixture has now reached a temperature of about 850 °C. In order to achieve maximum energy efficiency, Dyckerhoff feeds the heat exchanger with the hot air from the clinker cooler at the end of the rotary kiln. Thus, it is possible to supply less energy to the heat exchanger.

Delta Screws of the type VML 18, with a motor rating of 45 kW, a pressure of 2.25 bar and a volume flow of 1080 m³/h each, keep the transport network running from the storage silo to the kiln. Aerzen offers single-stage, oil-free screw compressors in different sizes, with volume flows between 950 und 15 000 m³ per hour. The units are designed as universal tools, dimensioned for maximum energy efficiency, offering the possibility of combining any compressors and accessory components on a modular basis. The compressors can thus be adapted to suit the relevant application.

2 Close cooperation in service too

Dyckerhoff exclusively applies technology which ensures maximum availability – supported by services. The cooperation with Aerzen on service level is very close, and the engineering always seeks to standardise as much as possible to limit the stocking of spare parts.

The company and its supplier work hand-in‑hand on preventive maintenance. As soon as the service technician from Aerzen sets off, the maintenance team in Lengerich begins the preparation work. Dyckerhoff’s engineers are well trained and experienced in blower technology. Therefore, the experts visit only to do fine-tuning jobs.

3 In continuous operation

Dyckerhoff operates about 130 units from Aerzen in Lengerich – most of them for 6000 to 7000 h per annum – scheduled operating standstill deducted, meaning that they are in quasi-continuous operation. In particular, the blowers installed at the rotary kiln need to provide maximum availability and high values for energy efficiency at the same time.

//www.aerzen.com" target="_blank" >www.aerzen.com:www.aerzen.com

Überschrift Bezahlschranke (EN)

tab ZKG KOMBI EN

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

tab ZKG KOMBI Study test

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.

This is a trial offer for programming testing only. It does not entitle you to a valid subscription and is intended purely for testing purposes. Please do not follow this process.